1. Introduction

Casting is a widely used manufacturing process in various industries, especially in the production of complex – shaped components such as lifting boxes. Lifting boxes play a crucial role in equipment like oil drilling and mining machinery. The quality of casting directly affects the performance and service life of these components. The material of the lifting box studied in this paper is ZG25CrNiMo, which has specific mechanical properties requirements. Due to its complex structure with an uneven wall thickness, special attention must be paid during the casting process to avoid defects such as shrinkage porosity and looseness. This paper aims to comprehensively explore the casting process design and optimization of the lifting box through theoretical analysis, process scheme comparison, and numerical simulation.

2. Structural Analysis of the Lifting Box

2.1 Geometric Dimensions and Shape Characteristics

The lifting box is mainly in the shape of a solid of revolution. Its external dimensions are 1040 mm×776 mm×933 mm, and it has a net weight of 1058 kg. The majority of the box wall has a thickness of 45 mm, but there are significant variations. The thickest part reaches 165 mm (excluding external convex platforms), and the thinnest part is 30 mm. This large difference in wall thickness leads to the formation of thermal nodes during the solidification process of molten steel, which is a major factor causing casting defects. A thermal node is an area where heat accumulates due to a larger mass of metal, resulting in slower cooling and potential shrinkage problems.

| Feature | Details |

|---|---|

| Overall Dimensions | 1040 mm×776 mm×933 mm |

| Wall Thickness (Most) | 45 mm |

| Wall Thickness (Thickest) | 165 mm |

| Wall Thickness (Thinnest) | 30 mm |

2.2 Influence of Structure on Casting Quality

The uneven wall thickness of the lifting box causes non – uniform heat dissipation during solidification. The thick – walled parts cool down more slowly than the thin – walled parts. As a result, when the thin – walled parts solidify first and shrink, the molten metal in the thick – walled parts cannot effectively compensate for the shrinkage, leading to the formation of shrinkage porosity and looseness. These defects can seriously affect the mechanical properties of the lifting box, such as its fatigue strength and load – bearing capacity. For example, shrinkage porosity can act as stress concentrators, reducing the fatigue life of the component under cyclic loading.

3. Process Scheme Formulation

3.1 Scheme One: Horizontal Molding and Vertical Pouring Process

3.1.1 Process Description

In this process, the model is divided into upper and lower halves. The model making is relatively simple, and it is convenient for molding and core – setting operations. After horizontal molding and core – setting, the mold is erected for pouring. Considering the structure of the lifting box, in order to ensure the density of the casting, risers must be placed at one end of the casting for feeding, and pouring is carried out at the other end.

| Process Step | Description |

|---|---|

| Model Division | Divided into upper and lower halves |

| Molding Method | Horizontal molding |

| Pouring Method | Vertical pouring after erecting the mold |

| Riser Placement | At one end of the casting for feeding |

| Pouring Location | At the other end of the casting |

3.1.2 Feasibility Analysis

However, in practical operation, regardless of which end the riser and runner are set, the placement of the riser is extremely difficult. It is hard to achieve precise positioning, which is not conducive to the operation of workers. This is mainly because the complex shape of the lifting box makes it difficult to find a suitable position for the riser to ensure effective feeding. Therefore, this process scheme is not suitable for the production of lifting boxes.

3.2 Scheme Two: Vertical Standing and Pouring

3.2.1 Scheme 2A: Vertical Standing and Pouring – Large Surface Upward

- Process Design: This scheme requires three – part (upper, middle, and lower) box – opening molding. To ensure effective feeding of the casting, especially for thick – walled and hot – spot parts, four risers with a size of ø300 mm×500 mm are initially determined and evenly distributed on the upper end face. The HZCAE11.0 software developed by Huazhong University of Science and Technology is used for numerical simulation of the casting process. The solidification simulation is carried out through the instantaneous filling of molten steel and the pure temperature field without considering fluid flow.

- Simulation Results and Analysis: The simulation results show that when the molten steel solidifies to 572 s, there are two obvious isolated areas in the middle – lower part of the lifting box casting. The risers have little effect on feeding these two areas. When solidification reaches 3552.41 s, the upper half of the lifting box has completely solidified, but significant shrinkage cavities are formed in the lower hot – spot areas. This will undoubtedly affect the fatigue strength and service life of the lifting box. So, this scheme is not advisable.

| Time of Solidification | Observation |

|---|---|

| 572 s | Two obvious isolated areas in the middle – lower part of the casting, and the risers have little feeding effect |

| 3552.41 s | The upper half of the casting is completely solidified, and significant shrinkage cavities are formed in the lower hot – spot areas |

3.2.2 Scheme 2B: Vertical Standing and Pouring – Large Surface Downward

- Process Advantage: In this process scheme, the thick – walled and hot – spot parts are placed at the top. In this way, the thin – walled parts at the lower part of the casting solidify first, and the upper hot – spot parts can be fed through the risers, achieving sequential solidification and obtaining a dense structure.

- Final Process Determination: Through the above – mentioned comparative analysis, the vertical standing and pouring process with the large surface facing down and the small surface facing up is finally determined as the most suitable process scheme for the lifting box casting.

4. Model and Core Design

4.1 Outer Mold

4.1.1 Mold Structure

The outer mold of the lifting box is divided into three parts: upper, middle, and lower. The upper part is the riser box, the middle box is the main body of the model, and the lower box is used for core positioning and runner inlet. The model is separated from the middle and removed upward and downward from the middle box.

| Mold Part | Function |

|---|---|

| Upper Part (Riser Box) | Accommodates the risers |

| Middle Part | Forms the main shape of the casting |

| Lower Part | Core positioning and runner inlet |

4.1.2 Special Design Considerations

- Activity Pad: There is an activity pad between the top end face of the model and the upper surface of the convex platform. When making the middle box, the pad and the outer mold are combined. When making the upper box, the pad is removed, and the molding sand in this area is connected to the upper box.

- Movable Blocks: A “260 mm×210 mm” convex platform model is made into a movable block. After the main body model is removed downward, the movable block is removed inward from the cavity. In addition, the two convex parts with flanges are made into “dovetail – groove” movable blocks with a 5° slope and the thinnest part thickness of 20 mm. After the outer mold is removed, these two movable blocks are removed radially inward, and the molding sand in the square holes is retained to form a complete square – hole shape with the 1# core.

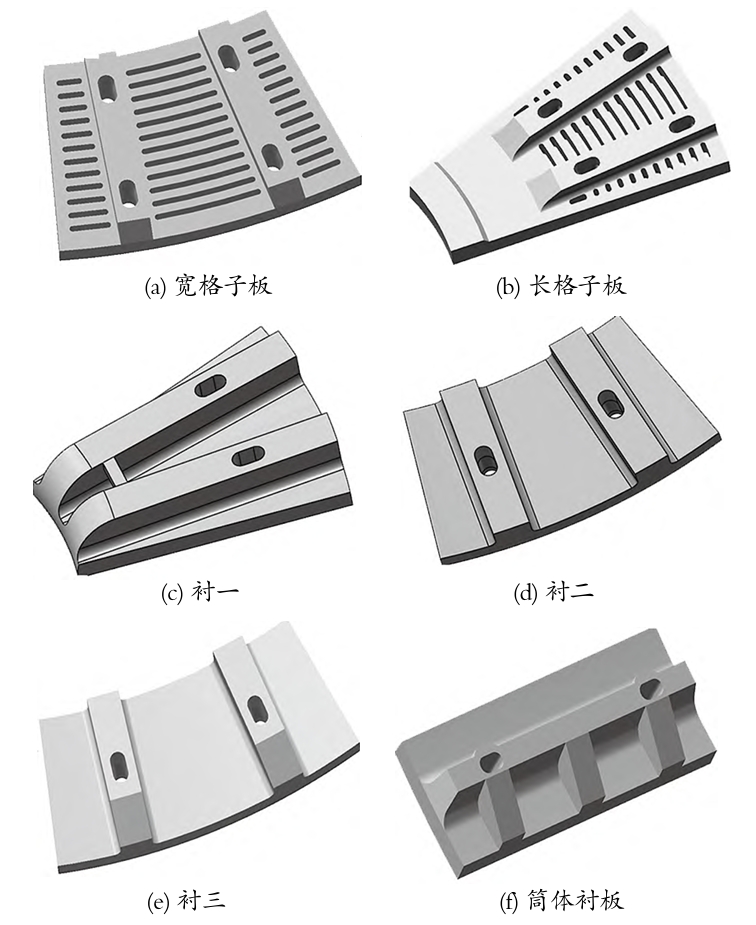

4.2 Sand Cores

4.2.1 Main Core

The main core has a core head height of 80 mm and a slope of 5°. Due to the position requirements of the convex platform on the outside of the core, the core head has a step for positioning, with a height of 40 mm and a thickness of 40 mm. The inner holes of the convex platforms are made on the core, and after setting the core, they are connected to the outer wall of the sand mold. Special attention should be paid to aligning the core head of the convex – platform flange with the sand mold formed by the movable block.

| Core Parameter | Value |

|---|---|

| Core Head Height | 80 mm |

| Core Head Slope | 5° |

| Step Height for Positioning | 40 mm |

| Step Thickness for Positioning | 40 mm |

4.2.2 Lifting Ring Shaft Hole Core

The lifting ring shaft hole core is made in pairs, and only one core box is required. The core head has a height of 40 mm and a slope of 5°.

4.2.3 Lifting Lug Core

The lifting lug core is also made in pairs with only one core box. The thinnest part of each side wall of the sand core is 30 mm. The outer mold is separated at the junction of this core and the conical surface of the box body to facilitate mold removal.

5. Riser Design

5.1 Riser Design Principles

The position of the riser directly affects its feeding efficiency and the quality of the casting. Riser design should be based on the structural characteristics of the casting. The casting is divided into several parts that need to be fed, and then the size and number of risers for each part are determined. Risers should be set at the highest or last – solidifying parts of the casting. If necessary, measures such as changing the position of the inner runner, adding subsidies, using chills, or special sands can be taken to promote sequential solidification towards the riser.

5.2 Riser Design Method

There are many methods to determine the size of the riser, such as the modulus method, the cubic – equation method, the feeding liquid – volume method, the proportion method, the shape – factor method, the hot – spot – circle method, and the shrink – pipe method. Due to the complex structure of the lifting box, it is difficult to determine the riser size with a single method. In this design, a combination of the modulus method and solidification simulation calculation is used.

5.3 Riser Configuration and Simulation Results

A waist – shaped open riser with dimensions “240 mm×360 mm×400 mm” and two cylindrical open risers with dimensions “ø240 mm×400 mm” are set at the top of the casting. After conducting the “filling + solidification” coupling simulation, the results show that although the shrinkage cavities in the thick – walled and hot – spot parts are basically eliminated, there is still looseness at the junction of the two walls in the middle of the casting and at the junction of the bottom lifting ring shaft hole and the inner side wall. This looseness cannot be eliminated by increasing the size of the riser. Therefore, an external chill is set at the bottom of the casting during molding production. The molding sand used is a special sand with a higher heat – storage coefficient than silica sand. These measures can control the sequential solidification of the casting through chilling effects, increase the feeding distance of the riser, and form a dense structure on the surface of the casting.

| Riser Type | Dimensions |

|---|---|

| Waist – shaped Open Riser | 240 mm×360 mm×400 mm |

| Cylindrical Open Riser | ø240 mm×400 mm |

6. Numerical Simulation of the Casting Process

6.1 Simulation Software and Its Role

The HZCAE11.0 software is used in this study. This software can simulate the filling and solidification processes of molten metal in the casting process. By inputting the geometric model of the casting, material properties, and process parameters, it can predict the formation of defects such as shrinkage porosity and looseness during the casting process. This helps engineers optimize the casting process design, such as adjusting the position and size of the riser, runner, and chills, to improve the quality of the casting.

6.2 Simulation Results and Process Optimization

Through multiple simulations, the effectiveness of different process schemes and riser designs can be evaluated. For example, in the simulation of the vertical standing and pouring process with different riser settings, the results show the distribution of solid – phase and liquid – phase regions at different times of solidification. Based on these results, the position and size of the riser can be adjusted. The final simulation results indicate that the optimized process with the determined riser configuration and the addition of an external chill can achieve better sequential solidification and reduce the occurrence of defects, although some looseness still exists but is within an acceptable range.

7. Conclusion

7.1 Summary of Process Design

The vertical standing and pouring process with the large surface of the lifting ring shaft hole facing down and the small end face of the lifting lug and thick side wall facing up is selected for the lifting box casting. The upper, middle, and lower three – part box – opening molding method is used, and risers, model bodies, core heads, and runners are set respectively. The wooden model consists of 1 outer mold (with the middle part separated), 3 core boxes, 1 movable – block pad, 1 movable block, and 2 dovetail – groove movable blocks.

7.2 Riser Design and Defect Control

The risers are designed using the modulus method and solidification simulation. One waist – shaped open riser and two cylindrical open risers are determined for feeding on the thick – walled end face. The simulation results show that the shrinkage porosity in the thick – and – large hot – spot parts is basically eliminated. However, looseness still exists at the junction of the two walls in the middle of the casting and at the junction of the bottom lifting ring shaft hole and the inner side wall. To address this, an external chill is set at the bottom to achieve better sequential solidification and feeding.

7.3 Future Research Directions

Although the current casting process design has achieved certain results, there is still room for improvement. Future research can focus on further optimizing the process parameters, such as the pouring temperature, pouring speed, and cooling rate, to further reduce the remaining looseness. In addition, exploring new materials and casting techniques, such as using advanced composite materials or novel casting methods like 3D printing – assisted casting, may also provide new solutions for improving the quality of lifting box castings.