Abstract:

The challenges associated with the traditional manual grinding process of cylinder block and cylinder head castings and introduces the adoption of robotic grinding technology as a solution. By analyzing the key difficulties and highlighting the critical technical aspects, this study aims to elucidate the overall scheme, action flow, and system composition of a robot grinding workstation. Furthermore, it emphasizes the utilization of floating fixtures, air-floating flexible motorized spindles, and laser detection systems to address the inconsistencies in castings and parts to be polished. The application of this technology is briefly explained, highlighting its effectiveness in improving grinding reliability and addressing labor issues.

1. Introduction

The cleaning process in casting production is one of the five essential procedures. It involves removing excess material, burrs, gating systems, vent pin residuals, and adhering sand from the casting surface to obtain finished castings. This process directly impacts the cost, efficiency, and quality of casting production. Traditionally, most casting enterprises rely on manual hammering and grinding wheel methods, which pose numerous challenges, including high labor costs, intense labor intensity, poor working conditions, low efficiency, and inconsistent cleaning quality. Moreover, with the evolving social landscape, labor protection concerns and difficulties in recruiting grinding workers have become common issues for casting enterprises.

The transition from manual to automated grinding methods, specifically focusing on the implementation and key technologies of robotic grinding for cylinder block and cylinder head castings in our factory.

2. Problems with Manual Grinding of Cylinder Block and Cylinder Head Castings

2.1 Original Cylinder Block and Cylinder Head Cleaning Process

Our factory produces gray iron and vermicular iron cylinder block and cylinder head castings for over ten types of engines, such as Dongfeng commercial vehicles and Dongfeng Cummins, using the same imported hydrostatic molding line. The cleaning process employs a mixed-flow production line.

After sand removal, the castings undergo rough shot blasting by a hanging chain shot blasting machine, followed by four-side grinding (not shown in the layout, located in another workshop and transported to the secondary shot blasting machine via basement motorized rollers and elevators). Subsequently, they are processed by a robotic shot blasting machine for secondary shot blasting. The castings are then conveyed and distributed to parallel manual grinding rooms where workers use pneumatic grinding wheels, pneumatic picks, and other tools to remove burrs, gating systems, vent pin residuals, and adhering sand from the surfaces and internal cavities of the cylinder block and cylinder head. After manual grinding, the cylinder block and cylinder head are conveyed to a U-shaped roller path for supplementary cleaning by workers. The supplementarily cleaned cylinder block and cylinder head undergo a third precision shot blasting by a robotic shot blasting machine, followed by inspection, rust prevention, and final storage.

2.2 Issues with Manual Grinding

- High labor costs due to a large workforce.

- High labor intensity and harsh working conditions.

- Low grinding efficiency.

- Inconsistent grinding quality due to worker discretion.

- Difficulty in recruiting grinding workers.

3. Automated Grinding Technology and Selection

Currently, the primary automated grinding technologies are machine tool grinding and robotic grinding. Table 1 compares the advantages and disadvantages of both methods.

Considering the relatively lenient precision requirements for casting cleaning and grinding (within 0.5mm is acceptable) and investment costs, our factory adopted robotic grinding, particularly since the maximum cylinder block weighs over 300kg, necessitating a robotic setup with grinding tools.

| Advantages | Disadvantages |

|---|---|

| Machine Tool Grinding | – High rigidity, strong bearing capacity, suitable for large cutting volumes.<br>- High processing accuracy.<br>- High processing efficiency. |

| Robotic Grinding | – High flexibility, adaptable to multiple varieties.<br>- Lower investment. |

Table 1: Comparison of Machine Tool and Robotic Grinding

4. Overall Technical Scheme for Robotic Grinding

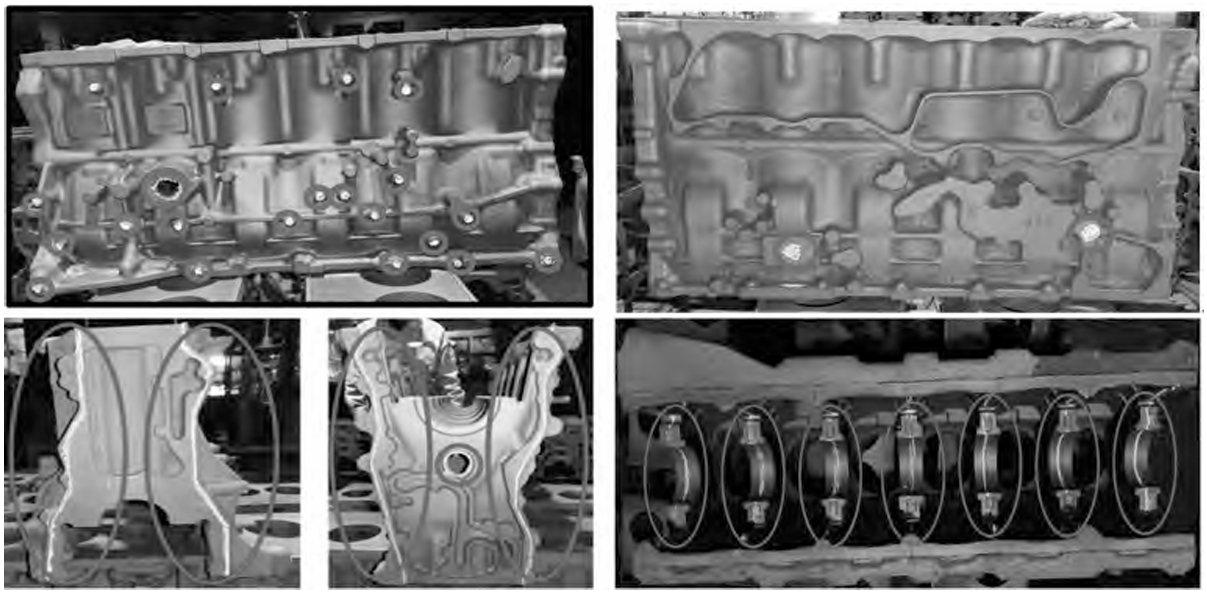

4.1 Grinding Areas and Requirements for Cylinder Block and Cylinder Head Castings

Taking a certain cylinder block as an example, the grinding areas include the gating system, vent pins, and parting line residuals on five surfaces, excluding the top surface used as the positioning surface. The grinding quality requirements are ±0.5mm for parting line residuals and less than 0.5mm for gating system residuals.

4.2 Key Challenges and Focus Areas of Robotic Grinding for Cylinder Block and Cylinder Head Castings

- Inconsistent Castings: Limited by casting process characteristics, castings have low dimensional accuracy, posing a significant challenge for positioning.

- Inconsistent Parts to be Polished: The shapes and sizes of burrs, gating systems, and vent pin residuals are uncertain. Since robots operate along fixed trajectories, they face varying loads, impacting their limited rigidity.

- Multi-variety Production on a Single Line: Our factory produces multiple types of cylinder block and cylinder head castings. A single robotic grinding workstation must cover all varieties.

- Grinding Tools: Rapid tool wear due to fixed robot trajectories affects costs and processing accuracy.

- Grinding Efficiency: Must match or exceed the efficiency of current manual grinding lines to align with subsequent processes.

4.3 Overall Plan

- Robot Selection: Based on robot load, cutting force, and processing needs for five surfaces of the cylinder block and cylinder head, the ABB IRB6700 series six-axis industrial robot with a 2.6m reach and 200kg payload was selected.

- Grinding Method: The robot holds the grinding tool while the cylinder block and cylinder head casting are fixed in position.

- Grinding Spindle: A domestic electric spindle cooled by cooling water, lubricated by oil and gas, driven by hydraulic pressure for tool changing, and sealed by blowing air was chosen. A domestic air-cooled chiller is used for spindle cooling.

- Double-station Grinding: To match the grinding cycle and productivity of subsequent processes, a double-station grinding setup with dual slides is adopted.

- Integrated Slide and Fixture Structure: Uses the “one face, two pins” principle for positioning and hydraulic clamping.

- Modular Fixture Design: To accommodate multi-variety cylinder block and cylinder head grinding on a single line and reduce fixture quantity, modular fixture design allows for the replacement and adjustment of positioning and clamping elements when switching varieties.

- Enclosed Grinding Unit: The grinding unit is enclosed in a sheet metal room, isolated from the dusty environment of the cleaning department to prevent interference with the precise operation of robots and electric spindles.

- Alarm Functions: The system includes alarms for spindle current, flexible floating air pressure of the spindle, tool clamping/unclamping pressure, and laser detection of workpiece position and posture.

5. Robotic Grinding Workstation and Key Technologies

5.1 Composition and Workflow of the Robotic Grinding Workstation

The robotic grinding workstation comprises an ABB IRB6700 series 200/2.6 six-axis industrial robot, a 20kW domestic air-floating electric spindle, a 16-tool disk tool magazine, dual-station in/out motorized roller paths, cylinder block and cylinder head positioning fixtures serving as slides, a hydraulic power station, a domestic air-cooled chiller, robot control cabinets, electrical control cabinets, an enclosed sheet metal room, etc. The sheet metal room is connected to the factory dust removal pipeline.

5.2 Key Technologies of the Robotic Grinding Workstation

5.2.1 Grinding Simulation

During the design and deployment of the robotic grinding workstation, comprehensive modeling and simulation were conducted using ABB’s RobotStudio software. This process not only covered the five critical grinding surfaces of cylinder block and cylinder head castings (including the left and right end surfaces, upper and lower case surfaces, and bearing shell surfaces) but also involved detailed trajectory planning, simulation debugging, and collision interference simulation. Through simulation technology, technicians can pre-evaluate and optimize grinding paths, ensuring that the robot can accurately and efficiently complete grinding tasks in actual operations while effectively avoiding collisions with workpieces or surrounding equipment. This significantly enhances the safety and reliability of grinding operations.

5.2.2 Reliability and Quality Control of Grinding Cylinder Block and Cylinder Head Castings

Cylinder block and cylinder head castings, due to their special casting process, often exhibit issues such as low dimensional accuracy and inconsistent grinding areas, posing significant challenges for robotic grinding. To overcome these challenges, the following key technologies and measures were adopted:

Reliable Fixture Design: To address the issue of inconsistent casting dimensions, a reliable fixture system was designed. This fixture employs the “one face, two pins” positioning principle, utilizing adjustable-height support screws and floating locating pins to ensure accurate positioning of the castings during grinding. Additionally, the fixture features hydraulic clamping functionality, reliably fixing the castings to prevent movement or deformation during the grinding process.

Application of Flexible Electric Spindle: To address the inconsistency in grinding areas, an air-floating flexible electric spindle was introduced. This spindle features automatic tool changing and adjustable flexibility based on grinding requirements. During the grinding process, when encountering uncertain shapes or sizes in the grinding areas, the flexible electric spindle can adaptively deflect, avoiding damage to the workpiece itself. Meanwhile, an overload protection device can timely alert and stop the grinding process when the feed rate or cutting volume is excessive, protecting the electric spindle and tools.

Assistance of Laser Detection System: To improve grinding accuracy and reliability, a laser detection system was also introduced. This system groups the grinding areas of the workpiece before robotic grinding and selects the appropriate grinding program based on the burr conditions of each area. By using laser sensors to detect the relevant planes of the burrs, the robot trajectory can accurately match the actual shape and size of the workpiece. For workpieces with excessive deviations, the robot will automatically return to the origin and prompt workers to inspect and confirm, thereby avoiding grinding quality issues caused by workpiece size errors.

In summary, through reliable fixture design, the application of flexible electric spindles, and the assistance of laser detection systems, the robotic grinding workstation can overcome many challenges encountered during the grinding of cylinder block and cylinder head castings, achieving efficient and precise grinding operations. At the same time, the application of these key technologies provides powerful support for improving the reliability and quality control levels of robotic grinding.