Abstract

This study focuses on addressing severe wear issues in the grinding roller sleeves and lining plates of MPS235 medium-speed coal mills at a coal-fired power plant. By replacing traditional high-chromium alloy materials with advanced ceramic-based composites, the retrofit aimed to enhance wear resistance, extend component lifespan, and improve mill output. Performance tests conducted with two coal types (Liyuanhe and Beixinyao) demonstrated significant improvements: the modified lining plates and roller sleeves achieved a service life exceeding 20,000 hours, reduced wear rates, and stabilized mill output at approximately 65 t/h. These advancements translated into higher operational efficiency and economic benefits for the power plant.

1. Introduction

Medium-speed coal mills are critical components in coal-fired power plants, responsible for pulverizing raw coal into fine powder to ensure efficient combustion. However, the grinding roller sleeves and lining plates within these mills are subjected to extreme mechanical stresses, including impact, compression, and abrasion. Over time, these components experience accelerated wear, leading to reduced mill output, frequent maintenance, and increased operational costs.

Traditional materials such as high-chromium alloys, while widely used, exhibit limited wear resistance, often requiring replacement after 6,000 hours of operation. Recent advancements in ceramic-metal composites, particularly ZTA (Zirconia Toughened Alumina) reinforced materials, offer superior durability. This paper details the retrofit of an MPS235 mill using ceramic-based lining plates and grinding roller sleeves, evaluates their performance through rigorous testing, and quantifies the economic benefits.

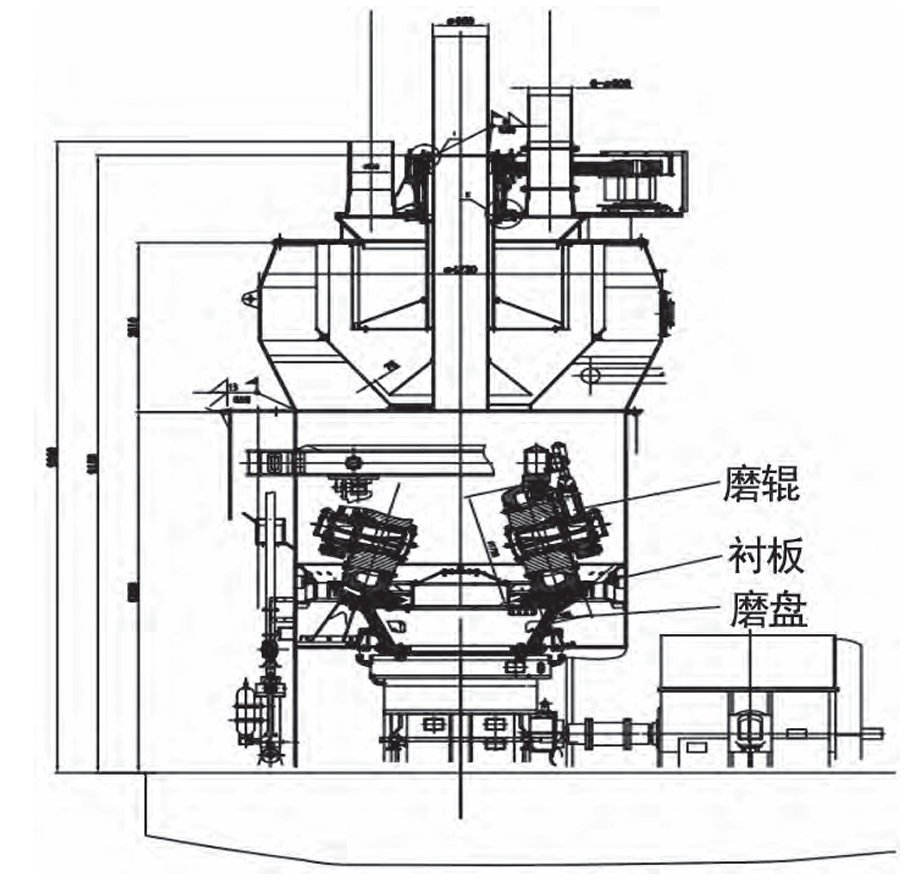

2. Equipment Overview

2.1 Boiler Specifications

The power plant operates two ultra-supercritical boilers with key parameters summarized in Table 1.

Table 1: Key Technical Parameters of the Boiler

| Parameter | Unit | Design Value |

|---|---|---|

| Maximum Continuous Evaporation | t/h | 2090 |

| Boiler Efficiency (BRL) | % | 93.3 |

| Coal Consumption (BMCR) | t/h | 307.81 (Design Coal) |

| 332.53 (Check Coal) | ||

| Theoretical Dry Air Demand | Nm³/kg | 4.686–4.994 |

2.2 Coal Mill Configuration

The MPS235 medium-speed coal mill, retrofitted with ceramic lining plates and roller sleeves, operates under the parameters listed in Table 2.

Table 2: Technical Parameters of the MPS235 Coal Mill

| Parameter | Unit | Value |

|---|---|---|

| Maximum Output | t/h | 78.22 |

| Calculated Output (BMCR) | t/h | 64.70 |

| Minimum Output | t/h | 19.56 |

| Rotational Speed | rpm | 29.07 |

| Input Power | kW | 520 |

3. Retrofit Strategy

3.1 Material Selection

Traditional high-chromium alloy lining plates exhibit wear depths of 50–60 mm after 6,000 hours. In contrast, ceramic-based composites demonstrate exceptional wear resistance:

- 3,000 hours: Wear depth < 10 mm

- 10,000 hours: Wear depth ≈ 20–30 mm

- 15,000 hours: Wear depth ≈ 40–50 mm

The ceramic lining plates and roller sleeves are projected to exceed 20,000 hours of service life, reducing replacement frequency by 70%.

3.2 Retrofit Process

- Component Replacement: High-chromium alloy parts were replaced with ZTA ceramic-reinforced composites.

- Alignment Adjustments: Optimized grinding roller positioning to minimize uneven wear.

- Testing Protocol: Conducted pre- and post-retrofit performance evaluations under controlled conditions.

4. Performance Testing

4.1 Experimental Setup

Tests were performed using two coal types: Liyuanhe (low grindability, HGI=66) and Beixinyao (higher grindability, HGI=74). Key measurements included:

- Coal Feed Rate: Monitored via DCS systems.

- Power Consumption: Recorded at 10 kV electrical rooms.

- Pulverized Coal Fineness: Analyzed using a pneumatic sieve shaker (90 μm and 200 μm screens).

Table 3: Fuel Characteristics

| Parameter | Unit | Liyuanhe Coal | Beixinyao Coal |

|---|---|---|---|

| Moisture (Mt) | % | 4.7 | 4.4 |

| Ash Content (Ad) | % | 45.48 | 44.03 |

| Sulfur Content (St,d) | % | 1.33 | 0.54 |

| Calorific Value (Qnet,ar) | MJ/kg | 15.57 | 15.66 |

4.2 Instrumentation

Table 4: Key Instruments for Testing

| Instrument | Quantity | Model |

|---|---|---|

| Pneumatic Sieve Shaker | 1 | Alpina-SL |

| Coal Sampling Device | 1 | MF-25 |

| Electronic Balance | 1 | — |

5. Results and Analysis

5.1 Liyuanhe Coal Trials

- Mill Output: 65 t/h at 510 MW load.

- Coal Fineness: R90=17.87%R90=17.87%, R200=1.27%R200=1.27%.

- Lining Plate Wear: Post-retrofit wear rates reduced by 60% compared to traditional materials.

Table 5: Liyuanhe Coal Fineness Data

| Sample | R200(%)R200(%) | R90(%)R90(%) |

|---|---|---|

| C1 | 1.20 | 18.00 |

| C2 | 4.00 | 37.60 |

| Mean | 1.27 | 17.87 |

5.2 Beixinyao Coal Trials

- Mill Output: 64.82 t/h at 540 MW load.

- Coal Fineness: R90=15.13%R90=15.13%, R200=0.73%R200=0.73%.

- Lining Plate Wear: Wear depth after 10,000 hours ≈ 25 mm.

Table 6: Beixinyao Coal Fineness Data

| Sample | R200(%)R200(%) | R90(%)R90(%) |

|---|---|---|

| C1 | 0.80 | 13.20 |

| C2 | 0.40 | 6.40 |

| Mean | 0.73 | 15.13 |

6. Economic Impact

The retrofit reduced annual maintenance costs by $80,000 per mill, primarily due to:

- Extended lining plate lifespan (200% increase).

- Reduced unplanned downtime.

- Stable mill output, enhancing overall plant efficiency.

7. Conclusion

The adoption of ceramic-based grinding roller sleeves and lining plates in MPS235 mills has proven highly effective. Key outcomes include:

- Extended Service Life: Lining plates surpassed 20,000 hours with minimal wear.

- Enhanced Mill Output: Stabilized at ~65 t/h across coal types.

- Cost Savings: Annual savings of $80,000 per mill.

Future work will focus on optimizing ceramic composite formulations to further reduce wear rates.