In my extensive experience developing automotive drivetrains, the transmission housing, or the ‘shell’, stands as one of the most critical and complex components. It is not merely a container but the foundational chassis that defines the spatial and functional integrity of the entire transmission system. A successful shell casting design is not born from CAD software alone; it is the result of a meticulous, iterative process where engineering design is inseparably woven with the realities of manufacturing and assembly. This article details my first-person perspective on this holistic approach, emphasizing the pivotal integration of design with process to create robust, manufacturable, and high-performance transmission shell castings.

The Integrated Design Flow: From Concept to Validated Product

The journey of a transmission housing begins with constraints and ends with validation. Rushing into detailed modeling without a systematic flow is a recipe for costly revisions and production issues. The following flowchart encapsulates the essential, iterative process I adhere to:

- Boundary Condition Definition: This is the foundation. Inputs include engine interface geometry (mounting points, output flange), internal component layout (gears, shafts, clutches), external packaging limits (vehicle underbody clearance), and performance targets (strength, NVH, weight).

- Preliminary Concept & Topology Optimization: Using these boundaries, I create a basic envelope. Modern tools allow for topology optimization early in the cycle. By defining keep-out zones for components and load paths from bearings, software suggests a material layout that maximizes stiffness-to-weight ratio. This often reveals efficient ribbing patterns and load-bearing walls for the final shell casting design.

- Detailed Design & Multi-Disciplinary Analysis: The optimized shape is developed into a solid model. Concurrently, several analyses are launched:

- Structural FEA: Static and dynamic load cases (shaft loads, mounting loads) are simulated to check stress and deformation. The goal is to stay well within the fatigue limits of the casting alloy.

- Process Simulation: This is where design meets manufacturability. Mold filling and solidification simulations for the shell casting process are crucial.

- Machinability & Assembly Review: The model is scrutinized for machining access, tool clearance, and logical assembly sequences.

- Prototype & Validation: Rapid prototyping (e.g., 3D printed sand molds for casting) creates physical samples for fit-check, rig testing, and ultimately, transmission-level durability tests. Results feed back into design refinement.

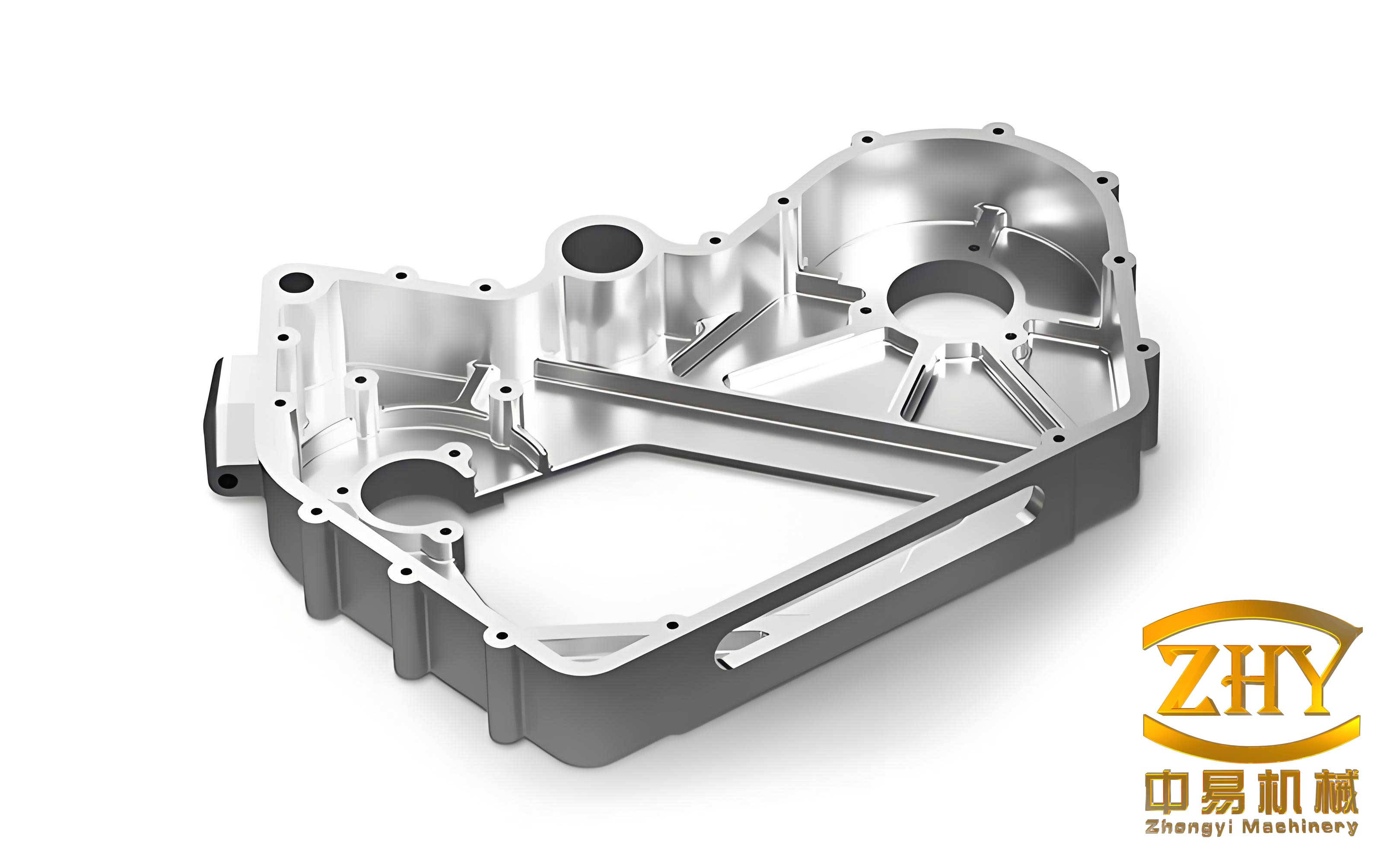

The image above illustrates a high-quality aluminum shell casting, showcasing the complex geometry and integrated features that are the end goal of this synergistic design process.

Casting Process: The Genesis of the Shell

Since most modern transmission housings are high-pressure die-cast aluminum, their design is fundamentally constrained and guided by the casting process. Ignoring these constraints leads to defects, high scrap rates, and compromised performance.

Wall Thickness Design: Uniformity is king. Sudden changes in wall thickness create hot spots leading to shrinkage porosity, which can leak under pressure. A core principle I follow is to maintain nominal wall thickness within a tight tolerance. While strength calculations might suggest thicker sections, the casting process often dictates otherwise. Reinforcement is achieved through strategic ribbing, not bulk. The table below summarizes key guidelines:

| Design Feature | Recommended Practice | Rationale |

|---|---|---|

| Nominal Wall Thickness | 3.0 mm ± 0.5 mm typical for Al die-castings | Ensures rapid, uniform solidification; minimizes weight and porosity risk. |

| Rib Thickness | 60-80% of adjacent wall thickness | Prevents hot spots at rib-wall junctions, reducing shrinkage. |

| Fillet Radii | Minimum R1.0 mm at internal corners; larger for stress-critical areas. | Improves metal flow, reduces stress concentration, and enhances mold life. |

| Draft Angles | 1° to 3° on surfaces perpendicular to mold opening. | Essential for part ejection without damaging the casting or mold. |

The pressure and velocity of molten metal injection are critical. A simple relationship governs the fill time to prevent cold shuts (premature solidification):

$$ t_{fill} \leq \frac{V_{cavity}}{A_{gate} \cdot v_{metal}} $$

where \( t_{fill} \) is the cavity fill time, \( V_{cavity} \) is the volume of the shell casting cavity, \( A_{gate} \) is the total cross-sectional area of the gate system, and \( v_{metal} \) is the injection velocity. Process simulation software solves the complex fluid-thermal dynamics, but this principle underscores the need for adequate gating.

Overflow Wells (Vents & Ladles): These are not an afterthought but a design feature. Strategic placement of overflow wells at the end of fill paths traps cold, oxide-laden metal and air, preventing them from becoming entrapped in critical sealing surfaces or bearing bore areas of the shell casting.

Machining Philosophy: Designing for Precision Manufacturing

A raw shell casting is a near-net-shape part; precision machining creates the functional interfaces. The design must enable accurate, stable, and efficient machining.

Datums and Location Strategy: I adhere rigidly to the “3-2-1” locating principle. The primary datum is a large, stable machined plane (often the mating surface to the engine or another housing). Secondary and tertiary datums are two precision-machined holes (or bosses) perpendicular to the primary plane. This “one face, two pins” system ensures repeatable positioning across all machining operations. The positional tolerance of these datum features on the casting is critical. The resultant machining error can be approximated by:

$$ \delta_{mach} = \sqrt{ \delta_{loc}^2 + \delta_{fix}^2 + \delta_{tool}^2 } $$

where \( \delta_{mach} \) is the total machining error, \( \delta_{loc} \) is the error from datum variation on the raw shell casting, \( \delta_{fix} \) is fixturing/clamping deformation error, and \( \delta_{tool} \) is tool wear/deflection error. Minimizing \( \delta_{loc} \) through robust casting design is my first responsibility.

Design for Machining Access: Features must be accessible to standard cutting tools. Deep, small-diameter bores or pockets with tight corner radii should be avoided. Where possible, I design sealing surfaces (for gaskets or O-rings) to be machined in a single, continuous tool path to guarantee flatness and surface finish (typically Ra ≤ 3.2 µm for static seals). The table below provides a checklist for machining-oriented design:

| Machining Feature | Design Guideline | Benefit |

|---|---|---|

| Bearing Bores | Provide continuous, unobstructed tool access from one side; include a lead-in chamfer. | Allows boring/reaming in one setup; improves bore roundness and finish. |

| Sealing Flanges | Ensure uniform flange width (min 5mm, 1.5x bolt diameter preferred). Keep surfaces clear of adjacent raised features. | Enables fly-cutting; ensures uniform clamping pressure for leak-free joints. |

| Threaded Holes | Design adequate boss thickness around holes. Follow standard tap drill depth/diameter ratios. | Prevents boss cracking during casting and provides sufficient thread engagement strength. |

| Mating Surfaces | Avoid interrupted cuts on critical sealing planes (e.g., by sinking bolt holes deeper). | Improves surface finish integrity and simplifies leak path sealing. |

Assembly Integration: Designing for the Production Line

The shell casting must facilitate, not hinder, the assembly of the transmission. This perspective influences several key design aspects.

Handling and Orientation Features: On the assembly line, the transmission is lifted, rotated, and positioned. I incorporate dedicated, non-functional pads or lugs designed for robotic grippers or overhead lifters. The line connecting these grip points should ideally pass through the center of gravity of the sub-assembly to prevent tipping. Similarly, support points on the assembly pallet are positioned to stably cradle the shell casting.

Sealing System Design: A multi-piece housing must be leak-tight. The design of the joint is paramount. I apply a bead of RTV (Room Temperature Vulcanizing) silicone sealant. To prevent excess sealant from being squeezed into the transmission interior—where it could break off and block oil passages—I design a continuous “anti-squeeze” or “glue trap” channel on the inner side of the bolt circle. The volume of this channel \( V_{channel} \) must accommodate the displaced sealant volume \( V_{disp} \), which is a function of the flange gap \( h \) and sealant bead cross-sectional area \( A_{bead} \):

$$ V_{disp} \approx A_{bead} \cdot P_{flange} \cdot \frac{h_{initial} – h_{final}}{h_{initial}} $$

$$ V_{channel} > V_{disp} $$

where \( P_{flange} \) is the perimeter of the sealing bead. This ensures contamination-free assembly.

Bolt Pattern & Joint Integrity: Bolt placement is a science. Bolts should be spaced evenly, and the “pressure line” between any two adjacent bolts should fall within the sealing flange width. A common rule is to space bolts at 6-7 times the bolt diameter. The clamping force \( F_{clamp} \) from a bolt torque \( T \) is roughly:

$$ F_{clamp} \approx \frac{T}{k \cdot d} $$

where \( d \) is the bolt diameter and \( k \) is a nut factor (~0.2). This force, distributed over the gasket area, must create a surface pressure exceeding the internal fluid pressure. My design ensures sufficient flange width and bolt count to achieve this while avoiding distortion of the shell casting.

Navigating Design Challenges: Lubrication and Dimensional Integrity

The most intricate aspects of housing design often involve secondary functions and cumulative tolerances.

Integrated Lubrication Management: The housing is not passive; its internal walls form the oil gallery network. I design cast-in channels to direct oil from the pump to bearings, clutches, and gears. Baffles and weirs are often cast-in to prevent windage loss from rotating gears (like the differential) and to ensure the oil pickup is always submerged. These features add complexity to the mold but are essential for system efficiency and are a hallmark of a well-integrated shell casting.

Bearing Bore Alignment Across Split Lines: This is arguably the greatest challenge in multi-piece housing design. A gear shaft supported by bearings in two separate housings requires near-perfect coaxiality. Misalignment induces bending loads, noise, and premature bearing failure. My strategy involves:

- Designing large-diameter, precision-machined locating dowel pins (typically 2) very close to the critical bearing bores to maximize angular alignment.

- Specifying tight positional tolerances for bearing bores relative to their respective housing’s datum system. For a DCT or automatic transmission, I typically specify a position tolerance of Ø0.06 mm for bearing bores relative to their housing’s dowel pins.

- Controlling the datum features on the raw shell casting to ensure the machined dowel holes themselves are accurately located.

The resulting system coaxiality \( \phi_{sys} \) can be statistically derived from the individual tolerances:

$$ \phi_{sys} = \sqrt{ \phi_{boreA}^2 + \phi_{boreB}^2 + \phi_{dowel}^2 + \phi_{mating\_surf}^2 } $$

where each \( \phi \) represents a tolerance contributor (bore position, dowel position, surface flatness). Keeping \( \phi_{sys} \) within 0.05 mm per 100 mm of span is a common target for quiet, durable gear operation.

Conclusion: The Shell as a System Integrator

Designing a transmission housing is an exercise in systems engineering. It requires balancing conflicting demands: minimal weight versus maximal stiffness, casting simplicity versus functional integration, and design elegance versus manufacturing cost. A successful shell casting is the physical manifestation of this balance. It begins with a deep understanding of the casting process to ensure a sound, leak-free foundation. It is then refined with machining and assembly needs as primary drivers, not afterthoughts. Finally, it fulfills its ultimate role as the precision-aligned, lubricated, and protected environment for the transmission’s core kinematics. By viewing the housing through this integrated lens—where every design decision is interrogated for its manufacturing and assembly consequence—we move from creating a mere component to delivering a robust, reliable, and producible system cornerstone. The process is iterative and demanding, but the result is a transmission shell casting that performs flawlessly on the road and efficiently on the production line.