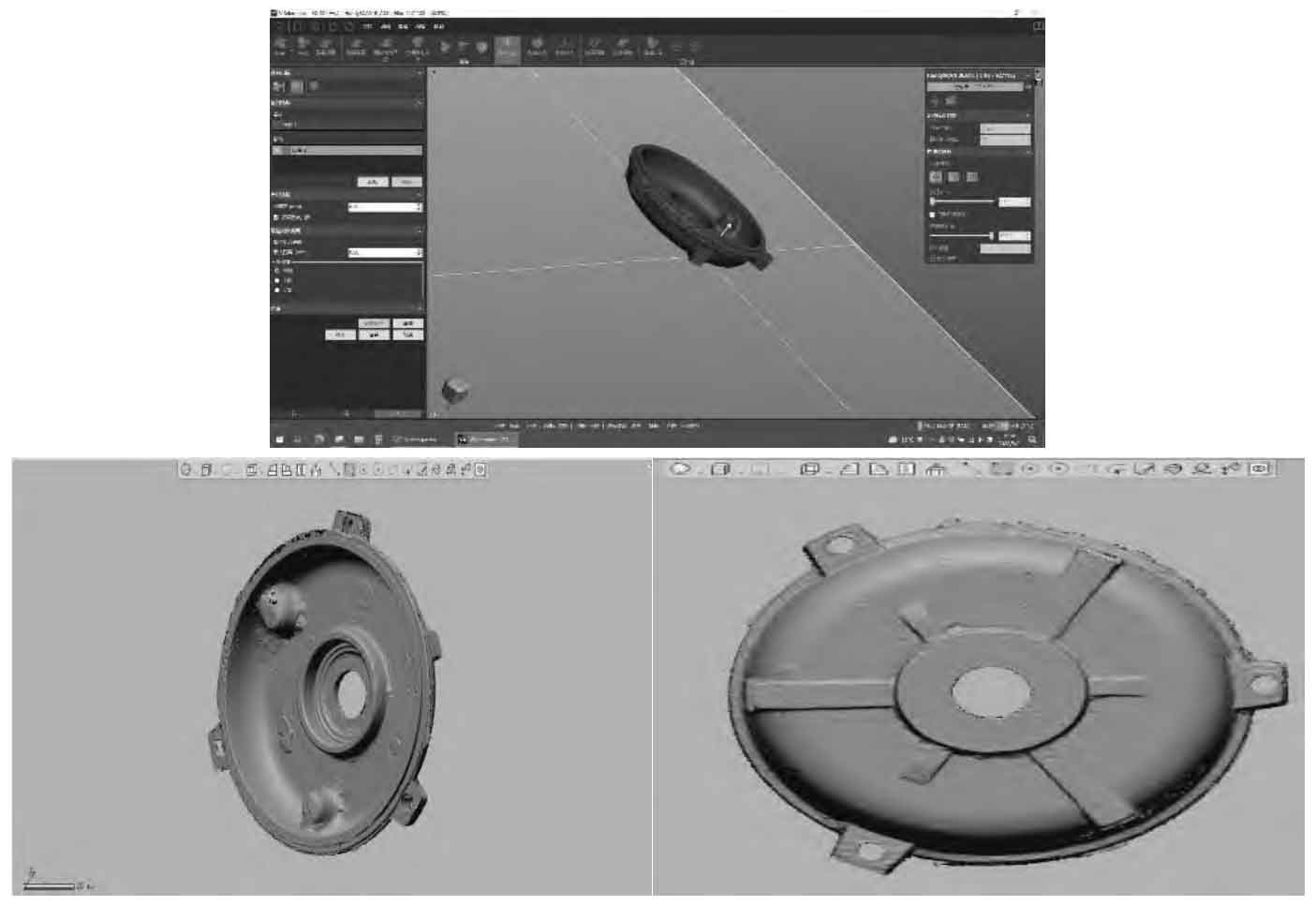

The model reconstruction is realized by reverse engineering, and the surface of the end cover casting is scanned by reverse equipment to obtain the point cloud file of the surface. Through point cloud processing, patch fitting and model establishment, the 3D model reconstruction of end cover casting is realized. The reverse equipment used in reverse is HandySCAN 3D scanning platform, equipped with a hand-held 3D scanner, which uses multiple laser lines to form a scanning area to scan the end cover casting. The equipment can track the relative motion of the end cover casting and the scanner during the scanning process, and can also automatically track the position of the surface points of the parts, achieving real-time scanning effect, and the scanning accuracy can reach 0.025mm.

For the scanning end cover casting, the end cover casting material and color shall have weak absorption of laser and good reflection consistency. The end cover can be sandblasted to meet the requirements, and the surface with serious color difference or high absorption rate can be sprayed with contrast agent to achieve the consistency of the surface characteristics of the end cover casting.