| Si | Mg | Ti | Sr | Zn | Cu | Al |

| 7.275 | 0.391% | 0.0518% | 0.0123% | 0.00089% | 0.00197% | 92.2% |

Table 1 shows the chemical composition analysis results of AlSi7Mg alloy for automobile. The raw material of the test die casting is made of Al-Si master alloy, pure aluminum and pure magnesium. Resistance graphite crucible is used for smelting. The crucible is heated to 680 ℃ in advance and kept warm, and then test materials other than pure Mg are added to the furnace for smelting; Then heat up and control the furnace temperature at 680~720 ℃. After complete melting, stop heating, reduce the molten metal to about 660 ℃, add pure magnesium block, then reheat, and start degassing and refining. When the melt temperature drops to the pouring temperature, let it stand for 10 minutes, and use Toshiba JS350 die-casting machine for die-casting molding, including: mold locking force 2600 kN, injection force 320 kN, injection speed 6 m/s, and filling speed 0.3~3.0 m/s, The die stroke is 350mm. The projected area of alloy sample is about 320mm × 220mm × 30mm。 The pouring temperature and initial mold temperature of alloy test are: pouring temperature 680, 700, 720 ℃, mold preheating temperature 150, 250, 350 ℃ (Table 2).

| Pouring temperature | 680°C | 700°C | 720°C |

| Mold preheating temperature | 150°C,250°C,350°C | 150°C,250°C,350°C | 150°C,250°C,350°C |

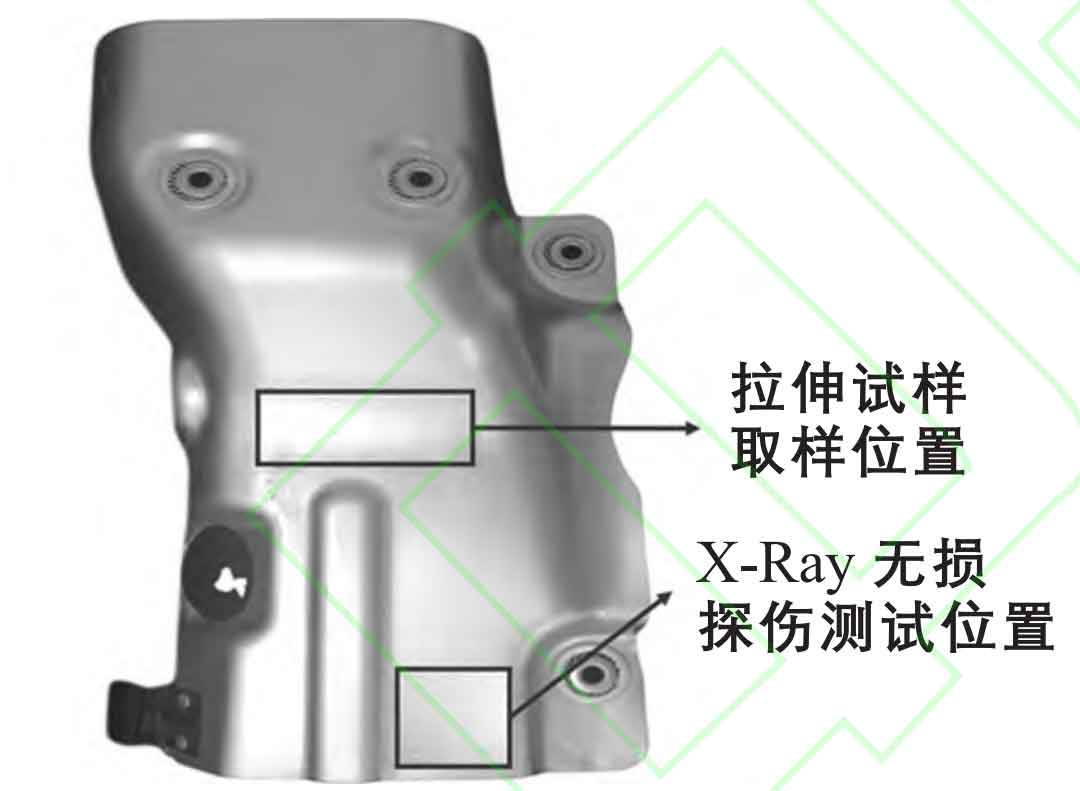

The die cast AlSi7Mg alloy parts are cut with a wire cutting machine to obtain tensile samples. The polishing equipment is PG-2C metallographic sample polishing machine, which uses hydrofluoric acid etching solution with a mass fraction of 0.5% for corrosion, and finally uses Zwick-Z150 electronic universal material testing machine for mechanical properties testing. The figure shows the appearance and test sampling position of the studied automobile parts, with the overall dimension of 200mm × 100mm × 100mm, the X-ray NDT position is at the internal stiffener of the part, the tensile sample sampling position is at the smooth part of the part center, and there is no stiffener structure in the corresponding interior.