1. Selection of smelting process

According to the material test results, the chemical composition of vermicular graphite cast iron cylinder block is formulated, as shown in Table 1. 500 kg spheroidizing ladle shall be used for tapping. 0.6% vermicular graphite cast iron vermicular agent and 0.6% inoculant (75 ferrosilicon) shall be added into the ladle in turn, and a certain amount of iron chips shall be covered on it. The tapping temperature is controlled at 1 480~1 510 ℃, and the pouring temperature is controlled at 1 380~1 420 ℃.

| C | Si | Mn | S | P | Cu | Sn |

| 3.6~3.9 | 2.1~2.4 | ≤0.5 | 0.03±0.005 | ≤0.03 | 0.6~0.8 | 0.03~0.05 |

2. Casting process design

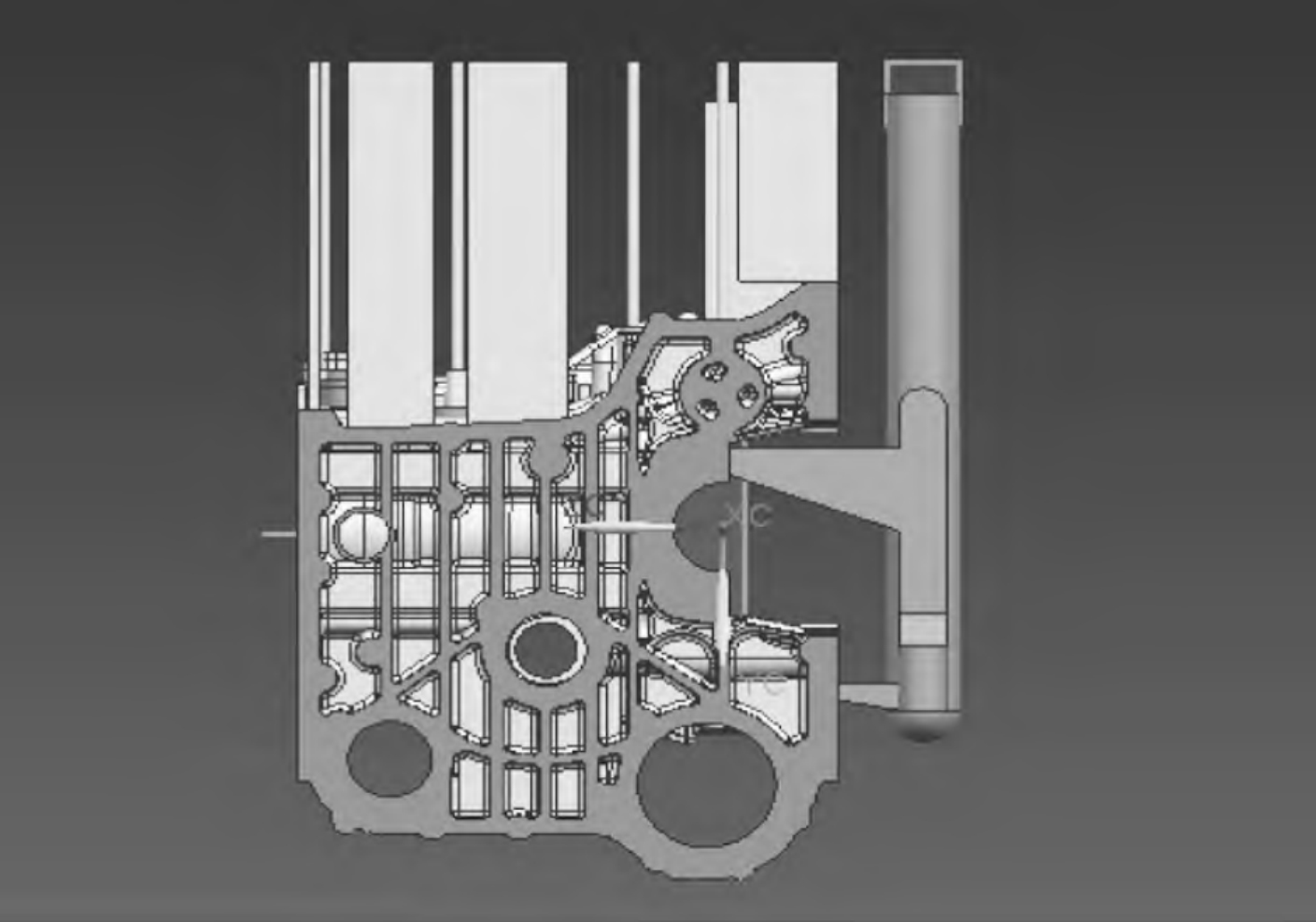

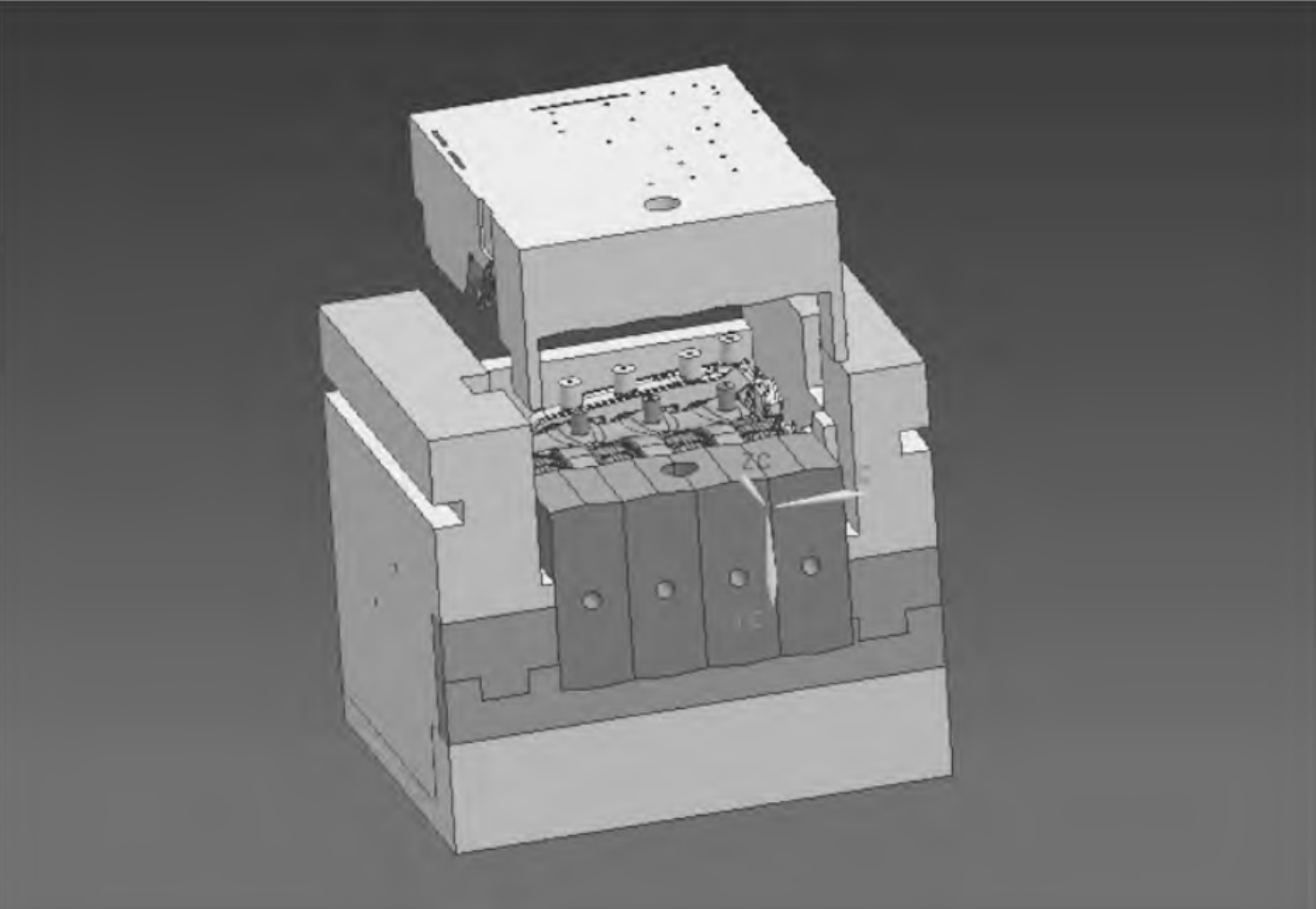

The casting process of vermicular graphite cast iron cylinder block is similar to that of gray iron, so the same horizontal casting scheme as gray iron cylinder block is adopted. The casting process design is shown in Figure 1. In order to reduce the trial production cost and shorten the trial production period, 3D printing technology is used to carry out the trial production of vermicular cast iron cylinder block. The sand mold of the cylinder block is divided into the following parts: 1 upper cover plate, 4 side plates, 1 lower bottom plate, 4 cylinder barrel cores, 1 oil channel core, 1 water jacket core, and 1 tappet chamber core. The assembly effect after parting is shown in Figure 2.

3. Cylinder block pouring and analysis

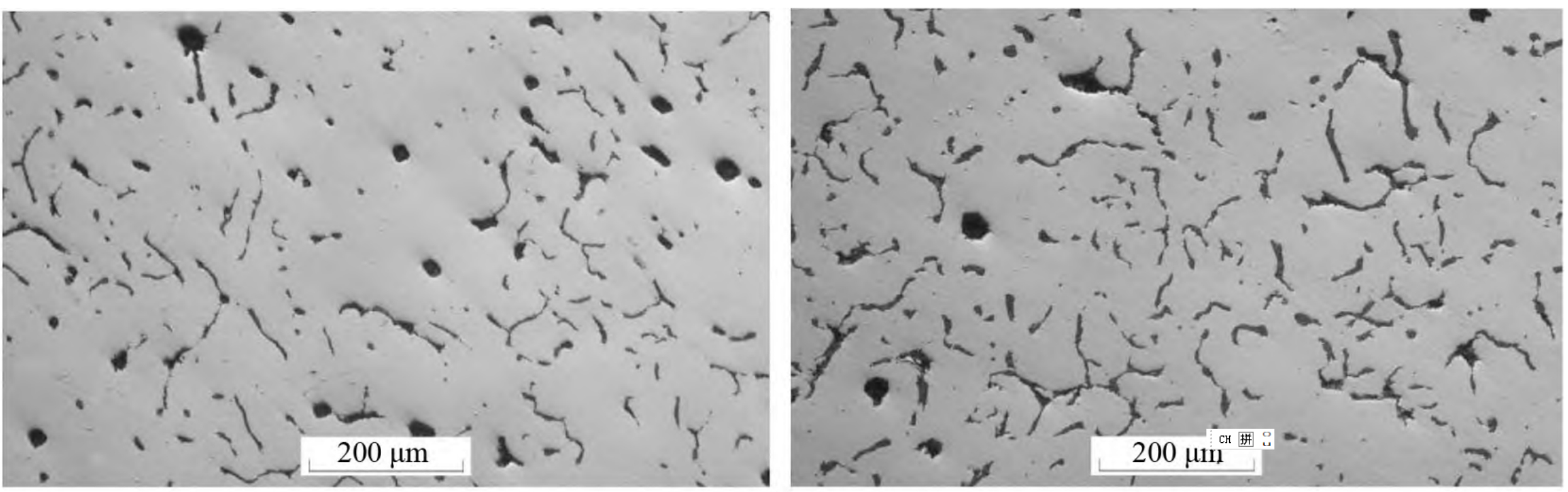

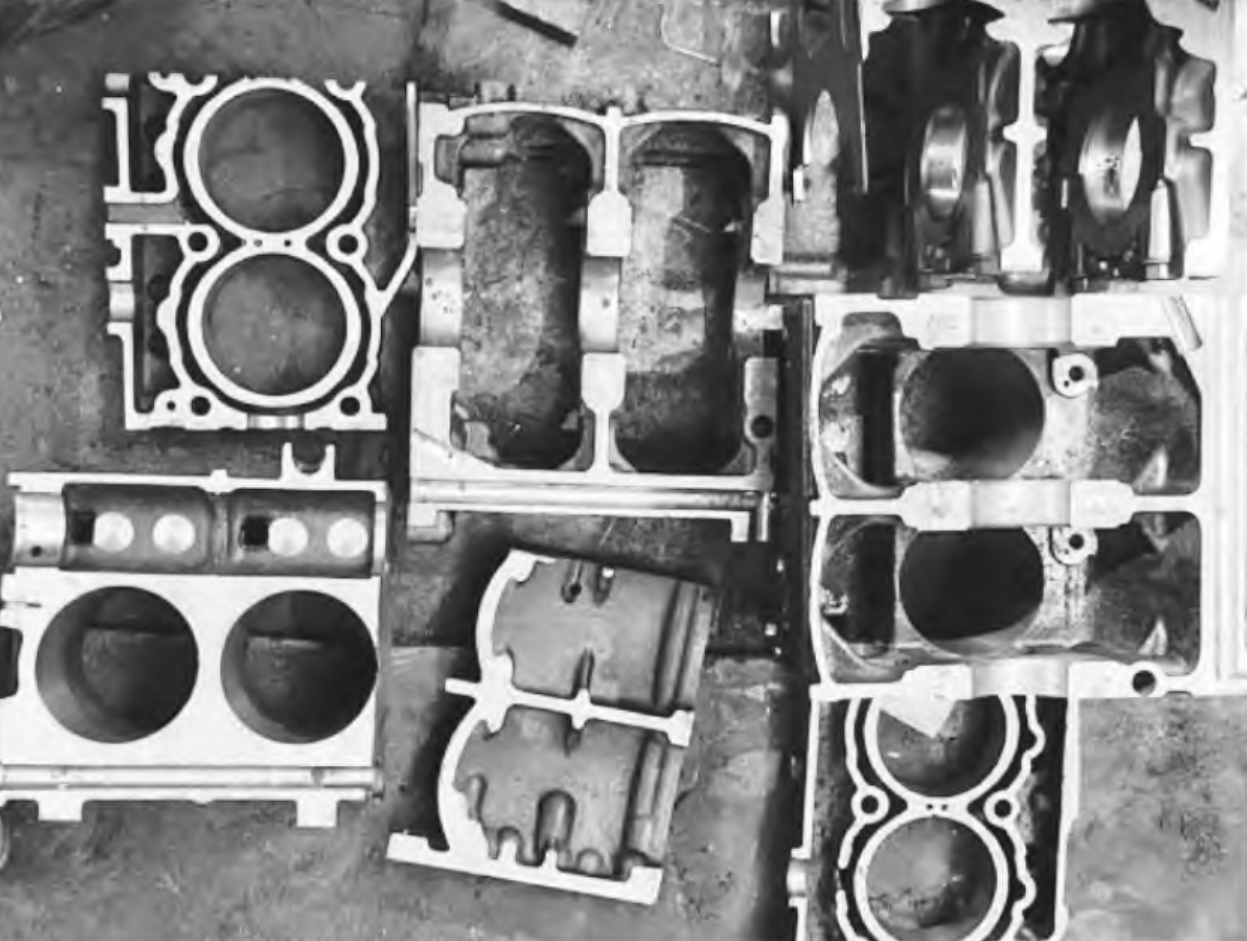

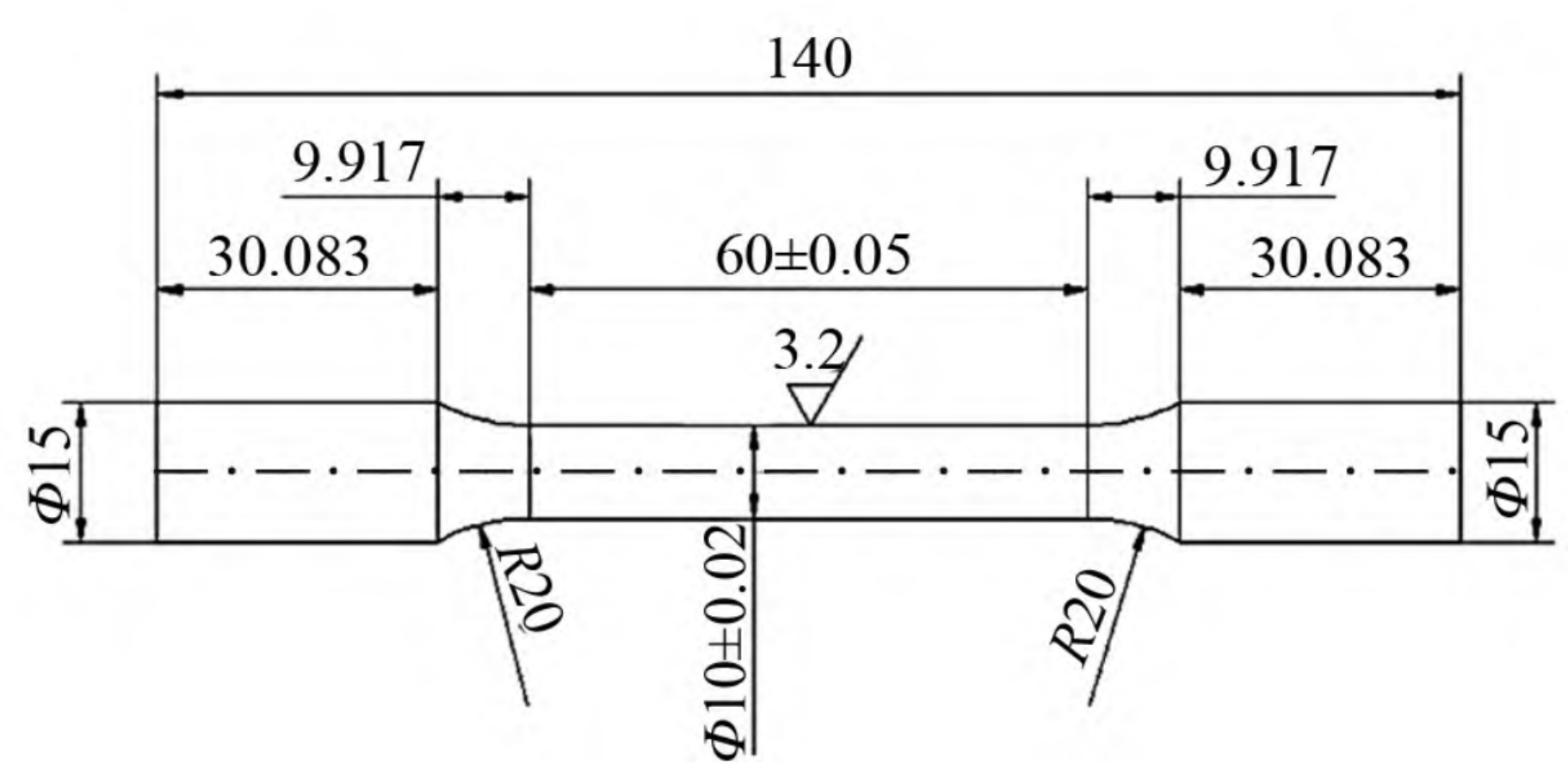

After 3D printing of sand mold according to the designed casting process, the cylinder block is brushed and dried with graphite paint, and then assembled and boxed. The molten iron is melted and pretreated according to the melting process before pouring. After cooling, the casting was dissected (Fig. 3), and no casting defects were found. Take samples from the bearing bush and cylinder barrel of the cylinder block respectively, and make standard samples with d0=10 mm according to GB/T26655-2011 to test their metallographic and mechanical properties. See Table 2 and Figure 4 for the test results.

| Sampling location | Yield strength/MPa | Tensile strength/MPa | Elongation/% |

| Bearing bush | 487 | 388 | 1.1 |

| Cylinder barrel | 509 | 402 | 1.9 |

The mechanical properties of the cylinder body meet the requirements of RT450, and the vermicular graphite cast iron vermicular rate of the body reaches more than 80%, which can fully meet the requirements of high-strength engine cylinder body.