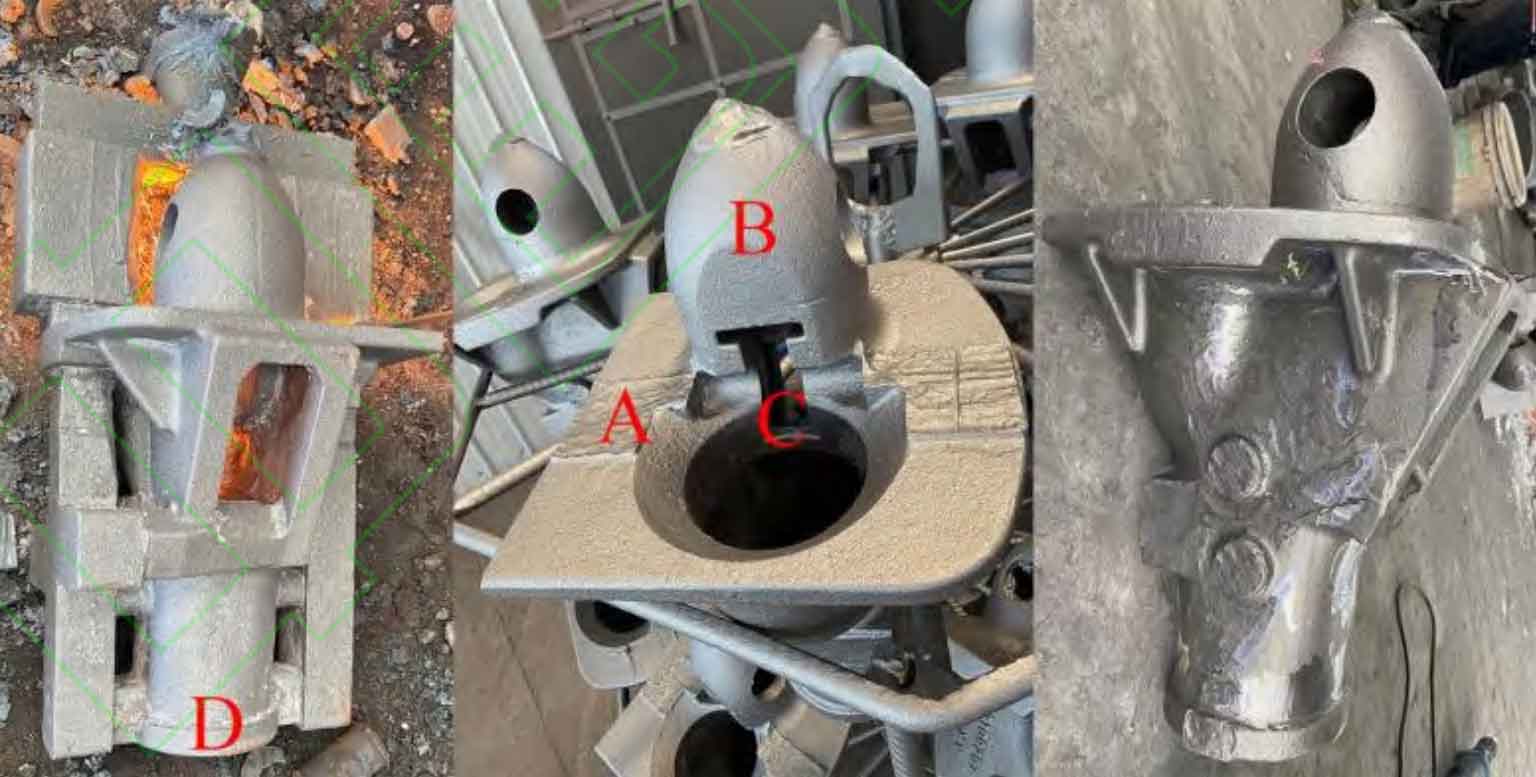

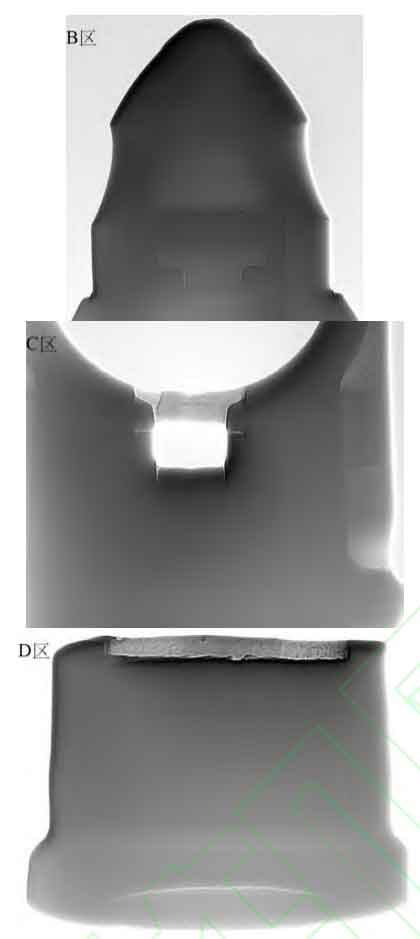

The coupler casting scheme adopting the gating system of scheme B is trial cast. The appearance of the trial cast is smooth and free of surface pores, inclusions and other macro defects, as shown in Figure 1 (a). One casting cutting section was randomly selected from the trial production parts of the same batch, and the X-ray nondestructive testing was carried out on the hook head, hook tongue connection part B and base part C. no cracks and shrinkage cavities were found in the key parts.

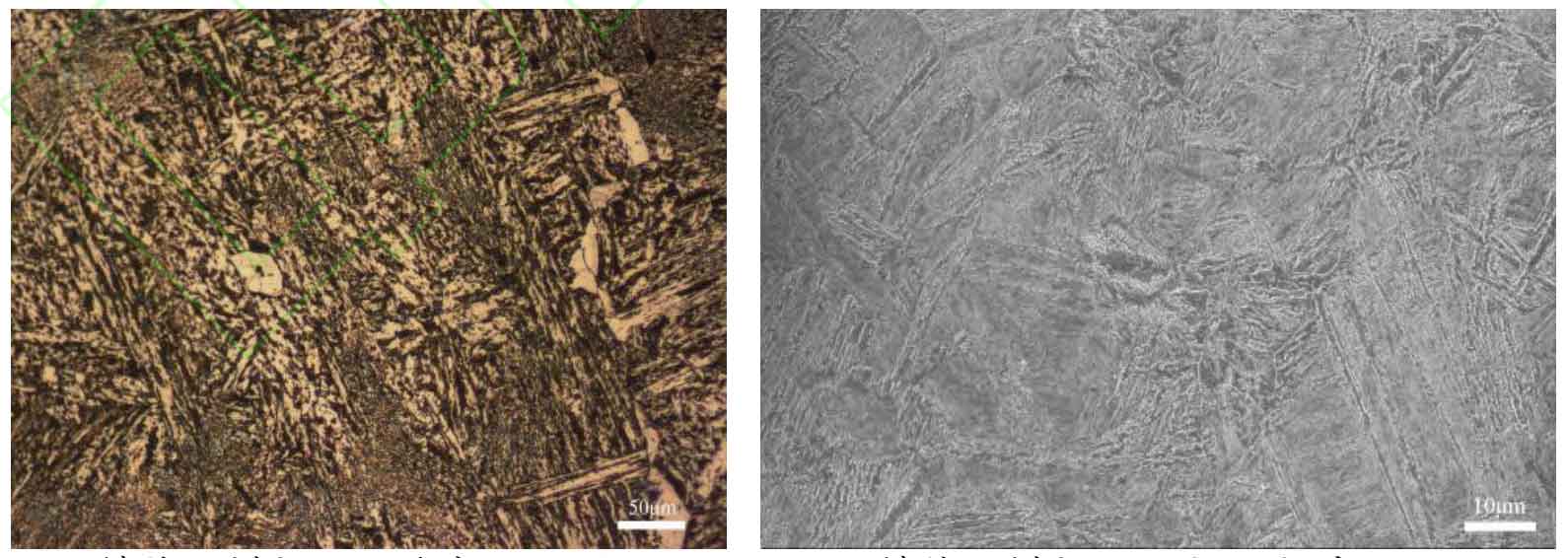

The microstructure of shoulder position a of the casting was observed. It was found that the grain size was uniform and the grain grade was in Grade 1 ~ 3, as shown in Figure 2, which met the requirements of TB / T 2942.2-2018 standard of China railway industry. The structure of the casting is mainly composed of fine grain ferrite distributed on the grain boundary of primary austenite and the mechanical mixture of intragranular needle strip ferrite and pearlite. The tensile strength at room temperature under as cast condition reaches 675mpa, and the performance meets the TB / T 2942-2015 standard of China railway industry.