Abstract

This article delves into the wear analysis and structural optimization of lining plates used in Semi-Autogenous Grinding (SAG) mills. Utilizing laser 3D scanning technology and software for data processing, we reconstructed 3D models and wear chromatograms of test lining plates from Wushan Copper Mine. The results revealed distinct wear patterns among different types of lining plates, prompting targeted structural optimizations to extend their service life and reduce downtime.

1. Introduction

Semi-Autogenous Grinding (SAG) mills are widely used in the mining industry for ore grinding. Lining plates, as crucial components, play a dual role in lifting the ore and protecting the mill cylinder. However, due to constant impact, abrasion, and slurry corrosion, lining plates undergo significant wear, necessitating regular inspection and replacement. This study aims to comprehensively analyze the wear of lining plates and propose structural optimizations based on the findings.

2. Methodology

2.1 Data Acquisition Using Laser 3D Scanning

Laser 3D scanning, a non-contact surveying technique, was chosen for its high speed and accuracy in acquiring spatial coordinate information over large areas. The test lining plates, randomly selected from a batch used in the Wushan Copper Mine Semi-Autogenous Grinding (SAG) mill, were cleaned to remove oil, dust, and other contaminants that could affect scanning accuracy. Magnetic reflective markers were then randomly attached to the surfaces and sides of the lining plates at intervals of approximately 10 cm.

2.2 Wear Analysis

The collected point cloud data was processed using specific software to generate 3D reconstruction models and thickness distribution maps for different regions. This not only allowed for the prediction of the remaining service life of the lining plates but also provided a basis for comprehensive wear analysis and subsequent design improvements.

3. Results and Discussion

3.1 Wear Characteristics of Different Lining Plates

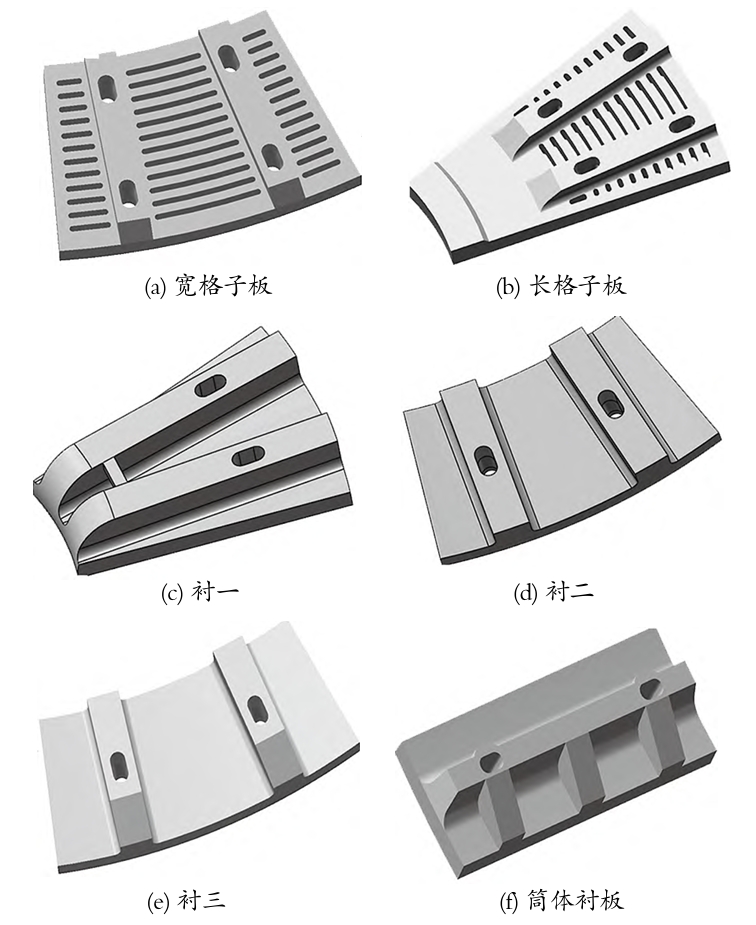

The 3D reconstruction models clearly showed the wear morphology of the lining plates. The following observations were made:

- Wide Lattice Plate and Long Lattice Plate: Wear was concentrated at one end, with the grid screening at the arcuate interface wearing more severely than other locations.

- Feed End Liners (Liner 1, Liner 2, Liner 3): Liner 2 exhibited the most severe wear, while Liner 1 showed the most uneven wear.

- Cylinder Liner: The addition of transverse reinforcing ribs effectively eliminated cracking, outperforming other liners.

Table 1: Summary of Wear Characteristics of Different Lining Plates

| Lining Plate Type | Wear Characteristics |

|---|---|

| Wide Lattice Plate | Wear concentrated at one end, severe grid screening wear at arcuate interface |

| Long Lattice Plate | Similar to wide lattice plate, wear concentrated at one end |

| Liner 1 | Most uneven wear, wear concentrated at the large head end |

| Liner 2 | Most severe wear |

| Liner 3 | Moderate wear |

| Cylinder Liner | Effective elimination of cracking with transverse reinforcing ribs |

3.2 Structural Optimization Design

Based on the wear characteristics, structural optimizations were carried out to prolong the service life and reduce the variance in failure times among different lining plates. The optimizations included:

- Increasing the height of lifting bars and thickness of some grid screenings for wide lattice plates, long lattice plates, and Liner 2.

- Modifying the shape of the lifting bars of Liner 1 from flat to left-low and right-high.

- Reinforcing the bolt hole positions of each lining plate with ribs.

Table 2: Structural Optimization Measures for Different Lining Plates

| Lining Plate Type | Optimization Measures |

|---|---|

| Wide Lattice Plate | Increased lifting bar height, increased grid screening thickness, reinforced bolt holes |

| Long Lattice Plate | Increased lifting bar height, increased grid screening thickness, reinforced bolt holes |

| Liner 1 | Modified lifting bar shape (left-low, right-high), reinforced bolt holes |

| Liner 2 | Increased lifting bar height, reinforced bolt holes |

| Liner 3 | No immediate optimization needed, monitoring for future needs |

| Cylinder Liner | Retained transverse reinforcing ribs, proven effective in eliminating cracking |

4. Conclusion

This study employed laser 3D scanning technology and reverse modeling software to measure and reconstruct 3D models of test lining plates from Semi-Autogenous Grinding (SAG) mill at Wushan Copper Mine. Wear analysis based on these models revealed distinct wear patterns among different types of lining plates. Subsequently, structural optimizations were proposed to extend their service life and reduce the variance in failure times.

4.1 Key Findings

- Wear Patterns: Wide lattice plates and long lattice plates showed wear concentrated at one end, with severe grid screening wear at the arcuate interface. Liner 2 exhibited the most severe wear, while Liner 1 showed the most uneven wear. The cylinder liner, with transverse reinforcing ribs, performed best in eliminating cracking.

- Structural Optimizations: Based on wear patterns, specific optimizations were implemented, such as increasing lifting bar height and grid screening thickness, modifying lifting bar shapes, and reinforcing bolt hole positions.

4.2 Implications

The proposed optimizations have the potential to significantly extend the service life of lining plates, reduce downtime for replacements, and lower operational costs. The methodology and findings of this study can serve as a reference for future wear analysis and structural optimization of lining plates in Semi-Autogenous Grinding (SAG) mills.

5. Future Work

Continued monitoring of the optimized lining plates is necessary to validate the effectiveness of the proposed changes. Additionally, further research could explore the use of advanced materials and coating technologies to further enhance the wear resistance of lining plates.