As the primary vulnerable component in ball mills, the lining plate undergoes continuous impact and extrusion friction from grinding media during operation, leading to significant wear. We adopt the Archard model to simulate the mixing of equal quantities of 5mm and 10mm media under varying lining plate configurations: absent liners, different shapes (rectangular/trapezoidal), and varying heights. Discrete Element Method (DEM) simulations using Rocky-DEM software provide insights into particle motion dynamics and their impact on lining plate degradation. Our methodology aims to optimize liner performance, enhance mill efficiency, and reduce wear through understanding stratification mechanisms and energy interactions.

1. Discrete Element Method Framework

The Archard wear model quantifies material volume loss from solid surfaces under particle impact. The fundamental equation is expressed as:

$$V = k \frac{F_\tau s}{H}$$

where \(V\) is the worn material volume, \(F_\tau\) denotes tangential force, \(s\) represents sliding distance, \(H\) is material hardness, and \(k\) is a dimensionless wear coefficient. For DEM implementation, the incremental form is applied:

$$\Delta V = C \Delta W_\tau$$

where \(\Delta V\) is volume loss per time step, \(\Delta W_\tau\) is tangential work done by particle-surface collisions, and \(C = k/H\). This formulation underpins our lining plate wear quantification.

2. Simulation Methodology

We modeled a simplified industrial mill cylinder (305mm diameter × 150mm length) with variable liner configurations. Binary steel media (5mm/10mm) were simulated at 25% filling rate and 50% critical speed (47 rpm). The filling rate is calculated as:

$$G = \frac{\pi}{4} D^2 L \gamma \psi$$

where \(G\) is media mass, \(D\) is mill diameter, \(L\) is cylinder length, \(\gamma\) = 4.8 t/m³ (bulk density), and \(\psi\) is filling percentage. Critical speed \(n_c\) = 96 rpm defines the rate parameter \(\phi_n\):

$$\phi_n = \frac{n}{n_c} \times 100\%$$

Material and contact parameters are detailed below:

| Parameter | Value |

|---|---|

| Cylinder & Particle Density (kg/m³) | 7,800 |

| Cylinder & Particle Poisson’s Ratio | 0.3 |

| Cylinder & Particle Shear Modulus (GPa) | 70 |

| Transparent Cover Density (kg/m³) | 1,500 |

| Transparent Cover Shear Modulus (GPa) | 0.198 |

| Contact Pair | Static Friction | Dynamic Friction | Restitution |

|---|---|---|---|

| Particle-Particle | 0.5 | 0.1 | 0.5 |

| Particle-Transparent Cover | 0.8 | 0.45 | 0.5 |

Simulations compared five configurations:

| Configuration | Liner Shape | Height (mm) | Lifter Count | Filling Rate | Speed Rate |

|---|---|---|---|---|---|

| No liner | – | 0 | 0 | 25% | 50% |

| Rectangular | Rectangle | 7.5 | 12 | 25% | 50% |

| Rectangular | Rectangle | 10 | 12 | 25% | 50% |

| Rectangular | Rectangle | 15 | 12 | 25% | 50% |

| Trapezoidal | Trapezoid | 10 | 12 | 25% | 50% |

3. Results and Analysis

3.1 Particle Dynamics and Stratification

Without lifters, small particles (5mm) concentrated centrally due to lower mass, while large particles (10mm) distributed peripherally. Introducing lifters altered axial distributions: small particles migrated toward cylinder ends, forming new stratification patterns, while large particle distributions remained stable. Velocity distributions revealed:

- No liner: Predominant cascading motion with large inactive zones

- Rectangular liners: High-velocity cataracting particles increasing volumetric efficiency but intensifying direct lining plate impacts

- Trapezoidal liners: Reduced high-velocity particles lowering fragmentation efficiency but mitigating wear

3.2 Wear Mechanisms and Energy Spectra

Energy dissipation spectra (10⁻¹⁷–10⁻¹ J range) showed higher collision frequencies for impact energy than dissipation energy. Large particles consistently exhibited higher energy transfer due to mass effects. Key observations:

- Rectangular liners increased small-particle collision frequency by 18% versus trapezoidal designs

- Dissipation energy from large particles correlated strongly with lining plate wear volume (\(R^2 > 0.89\))

- Impact energy contributions were negligible in Archard predictions, highlighting model limitations

Wear patterns consistently showed maximum degradation at lifter leading edges due to direct impingement.

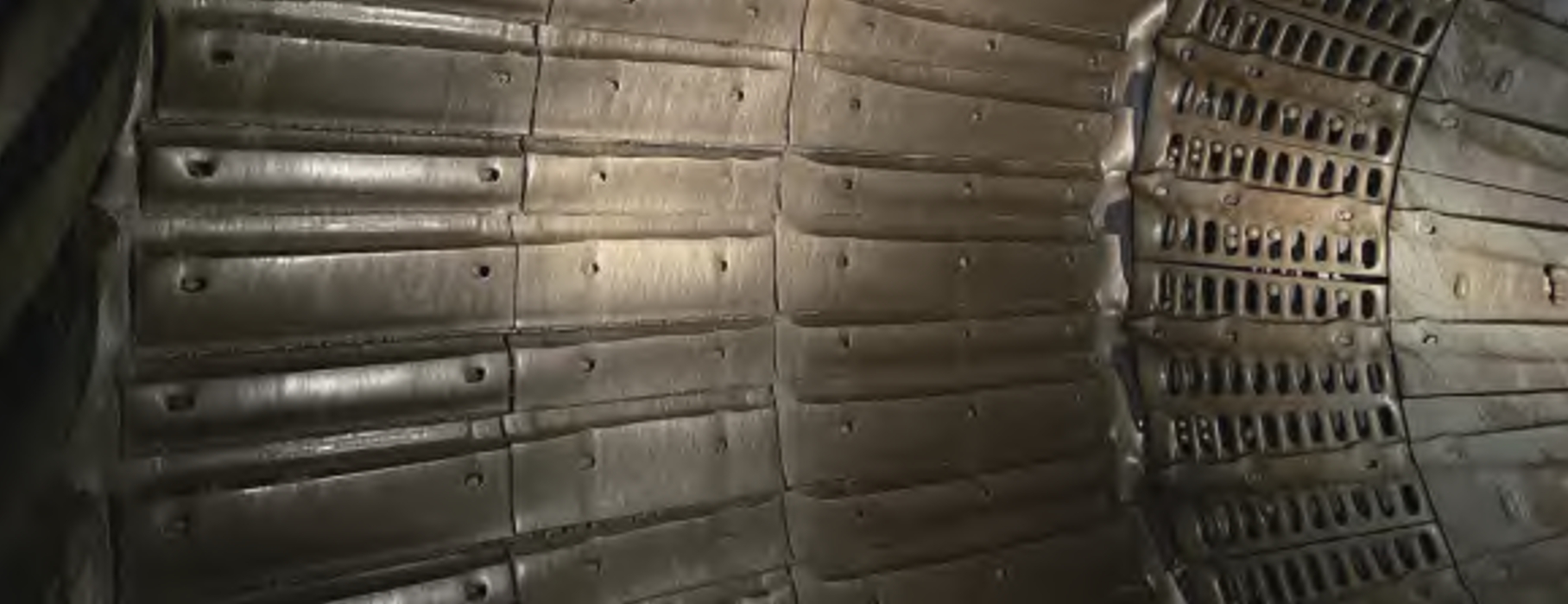

3.3 Liner Geometry Effects

Lining plate shape critically influenced wear:

- Rectangular vs. Trapezoidal: 22% higher wear volume for rectangular profiles due to intensified particle-liner engagement

- Height variation: Increasing lifter height from 7.5mm to 15mm reduced cylinder wear by 35% but increased lifter wear by 28%

Radial wear displacement maps confirmed asymmetric wear profiles concentrated at impact zones. Volume loss measurements after 50-100s simulations revealed:

- No-liner configuration: Extreme wear (terminated at 50s to avoid numerical instability)

- 10mm trapezoidal liners: Minimal volume loss (benchmark case)

- 15mm rectangular liners: 40% less wear than 7.5mm counterparts

4. Conclusions

- Particle stratification originates from end-wall effects and differential lifter lifting capacities. Without lifters, size-based radial segregation occurs. Introducing lifters triggers axial migration of small particles while large particles remain stable. This directly affects impact distribution on the lining plate.

- Rectangular lifters increase lining plate wear by 22% compared to trapezoidal designs due to enhanced particle engagement. However, increasing lifter height reduces cylinder wear by transferring energy to reinforced structures.

- The Archard model underestimates wear by neglecting impact contributions. Large-particle dissipation energy (\(>10^{-2}\) J) correlates strongly with observed wear, while impact energy remains unaccounted for. Future models must integrate impact mechanics for accurate lining plate wear prediction.

Optimizing lining plate geometry requires balancing fragmentation efficiency and wear resistance. Trapezoidal profiles and increased heights demonstrate significant wear reduction, extending liner service life in binary-media grinding systems.