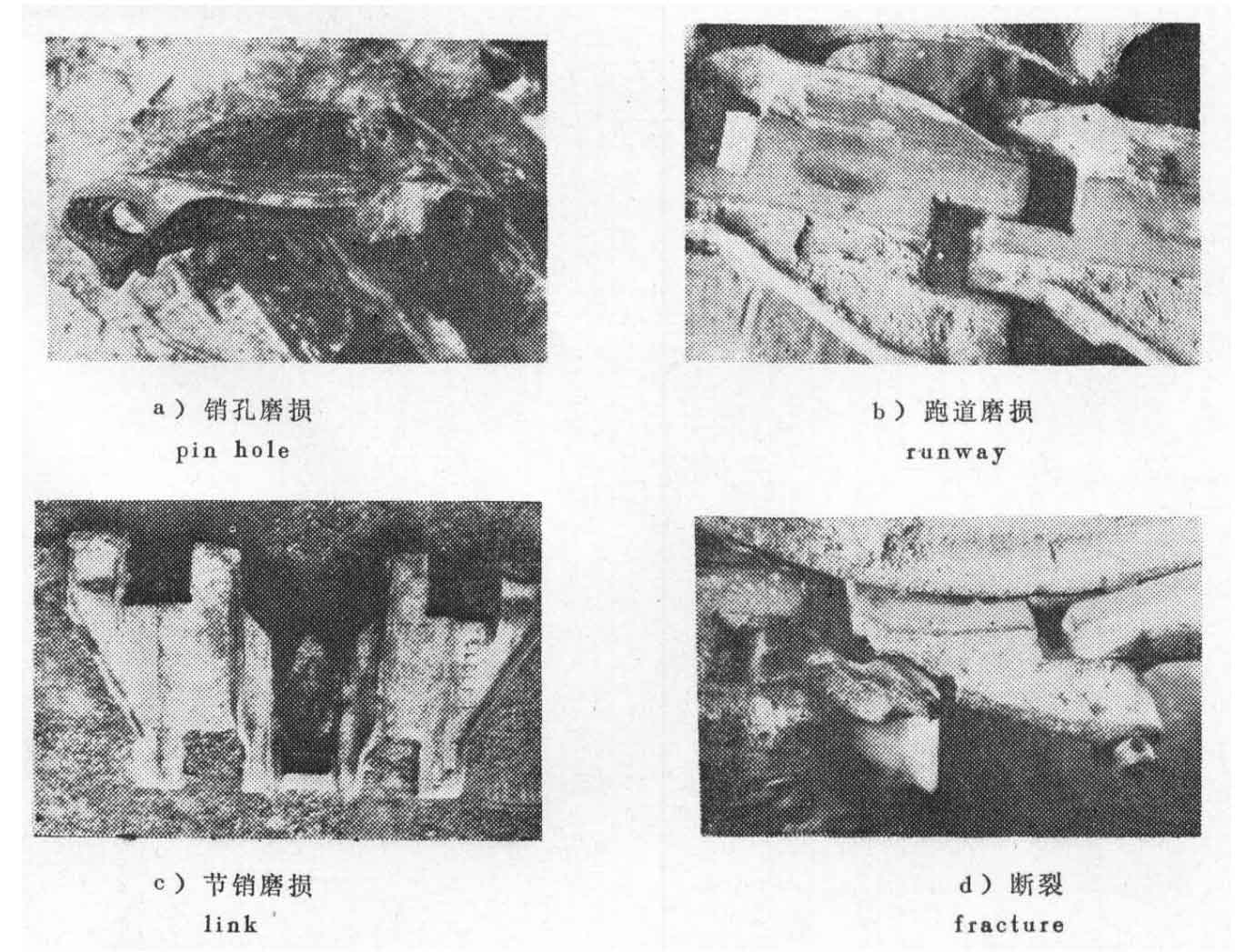

The working conditions of tractor track shoes are relatively poor. The relative motion characteristics and tribological characteristics of the contact parts at the joint are very inconsistent. Therefore, its wear failure type is more complex than other parts such as plough birch, rake blade and so on. The service life of tractor track shoes is also affected by the characteristics of soil abrasive particles, environmental water and corrosive substances. The data show that the service life of the existing tractor high manganese steel track shoes in paddy soil is 600-1000 hours, 1000-3000 hours in sandy soil area and 4000-6000 hours in clay and black soil area. Therefore, the service life of tractor track shoes separated from soil and medium conditions is not accurate. Due to the different characteristics of soil abrasive particles, tractor track shoes will show “priority wear” in some parts in different areas. For example, in paddy field, the pin hole is mainly worn and pulled into a trumpet shape and scrapped, but other parts are rarely worn. Fig. a, in clay and black loam, the runway is usually “preferentially” thinned and collapsed Fig. B, while in sandy soil, the pitch pin is worn first and scrapped Fig. c. In addition to wear failure, there is also the fracture damage form caused by microcracks Fig. d.

Let’s analyze the stress characteristics and wear characteristics of various parts of tractor track shoes:

The knuckle pin mouth is the most stressed part of the tractor track shoe, and the contact stress here is said to reach 910mpa.. Due to the impact of the gear teeth, according to the calculation of 2000 working hours in Zaotian, the joint pin of the tractor track shoe has to bear more than 6.86 million small energy and multi impact.

The contact stress between runway and tractor track shoe is 125mpa. The contact stress of the pin hole is about 6.8mpa. In the middle of these parts, there are often soil hard abrasives, forming three body abrasive wear with a small amount of impact and under the action of extrusion and other stress. The tooth claw part is in direct contact with soil and sand. This part will be seriously worn only when it works under hard sand and stone conditions. The above wear characteristics can be confirmed by the microscopic analysis and observation of the actual wear surface of tractor track shoes. These observations also show that the stress state and wear conditions of tractor track shoes are complex. Therefore, it is very difficult to use a simple simulation test method to fully represent the wear characteristics of each part of tractor track shoe under various soil conditions.