Abstract:

This paper presents a comprehensive analysis and repair process for the crack defects observed in ZG15Cr1Mo1V steel castings used for high-pressure combined main steam valves in a 300MW supercritical coal-fired power plant. The study investigates the root causes of crack formation, evaluates the suitability of repair materials and techniques, and details the step-by-step repair process. Special emphasis is placed on ensuring repair quality, preventing further cracks, and restoring the integrity of the castings to their original specifications. The paper concludes with a discussion on the effectiveness of the repair method and its potential applications in similar steel casting repair scenarios.

1. Introduction

Steel castings are widely used in various industrial applications, particularly in power generation, petrochemical, and heavy engineering sectors, due to their ability to withstand high temperatures, pressures, and corrosive environments. However, steel castings are prone to crack defects during casting, heat treatment, or during service under severe operating conditions. These cracks can significantly compromise the structural integrity and functionality of the components, necessitating timely and effective repair measures.

ZG15Cr1Mo1V is a low-alloy heat-resistant steel casting material commonly used for critical components such as high-pressure steam valves due to its excellent creep resistance, thermal fatigue resistance, and high-temperature strength. Nevertheless, crack defects have been reported in ZG15Cr1Mo1V castings, particularly under high-temperature and pressure conditions.

This paper focuses on the repair process of crack defects in ZG15Cr1Mo1V steel castings used in high-pressure combined main steam valves of a 300MW supercritical coal-fired power plant. The study aims to provide insights into the root causes of crack formation, the selection of appropriate repair materials and techniques, and the detailed repair process, with a focus on ensuring the quality and durability of the repaired casting.

2. Material and Defect Description

2.1 Material Overview

ZG15Cr1Mo1V is a low-alloy steel casting material that exhibits excellent mechanical properties at elevated temperatures. Its chemical composition (Table 1) and mechanical properties (Table 2) make it suitable for applications requiring high-temperature resistance and creep strength.

Table 1: Chemical Composition of ZG15Cr1Mo1V Steel Casting (wt%)

| Element | C | Mn | Si | Cr | Mo | V | S | P | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.23 | 0.35 | 0.09 | 2.59 | 0.65 | 0.01 | 0.001 | 0.001 | 4.8 |

Table 2: Mechanical Properties of ZG15Cr1Mo1V Steel Casting

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | ≥490 | MPa |

| Yield Strength | ≥343 | MPa |

| Elongation | ≥14 | % |

| Reduction of Area | ≥30 | % |

| Impact Toughness | ≥29.4 | J |

| Hardness | 140-200 | HB |

2.2 Defect Description

During routine maintenance inspections in 2022, crack defects were detected in the high-pressure combined main steam valves of a 300MW supercritical coal-fired power plant. The valves, made of ZG15Cr1Mo1V steel casting, exhibited significant cracks on the internal surfaces of the steam inlet chamber. The cracks were found to be deep (up to 40mm) and extensive, compromising the structural integrity of the valves.

3. Root Cause Analysis

Crack formation in steel castings can be attributed to various factors, including material properties, casting process, heat treatment, and service conditions. The following analysis explores the potential root causes of crack defects in the ZG15Cr1Mo1V steel castings:

3.1 Material Properties

ZG15Cr1Mo1V is a low-alloy steel with good high-temperature strength and creep resistance. However, the material’s microstructure and properties can be sensitive to casting defects, such as porosity, inclusions, and segregation, which can serve as stress raisers and initiate cracks.

3.2 Casting Process

Casting processes can introduce defects such as porosity, inclusions, and cold shuts, which can lead to stress concentrations and crack initiation. Inadequate pouring and venting during casting can also result in uneven cooling rates and thermal stresses, contributing to crack formation.

3.3 Heat Treatment

Incomplete or improper heat treatment can leave residual stresses in the casting, which can cause crack propagation under service conditions. Inadequate stress relief can also lead to the formation of new cracks.

3.4 Service Conditions

High-temperature and pressure cycling during operation can cause thermal fatigue and stress corrosion cracking in the steel castings. These conditions, coupled with residual stresses, can accelerate crack propagation.

4. Repair Material and Technique Selection

The selection of an appropriate repair material and technique is crucial for successful crack repair in steel castings. The following factors were considered in the selection process:

- Compatibility with the base material: The repair material should have similar chemical composition and mechanical properties to the base material to ensure a seamless bond.

- Weldability: The material should be easily weldable using conventional welding techniques.

- Resistance to crack propagation: The repair material should have high crack resistance under service conditions.

- Post-weld treatment requirements: The material should either require minimal post-weld treatment or be compatible with commonly used treatments.

Based on these considerations, ENiCrMo-3 nickel-based welding consumables were selected for the repair process. ENiCrMo-3 offers several advantages, including:

- Good compatibility with ZG15Cr1Mo1V, minimizing the risk of galvanic corrosion.

- Excellent weldability and crack resistance.

- Low tendency to form brittle intermetallic phases during welding.

- Minimal post-weld heat treatment requirements.

5. Repair Process

The repair process for the ZG15Cr1Mo1V steel casting cracks was meticulously planned and executed to ensure the highest quality repair. The following steps outline the repair process:

5.1 Preparation

- Safety Precautions: Ensure all safety precautions are in place, including proper ventilation, fire protection, and personal protective equipment.

- Disassembly: Disassemble the affected valves and thoroughly clean the casting surfaces to remove any contaminants or corrosion products.

- Inspection: Conduct a detailed inspection of the crack defects using non-destructive testing (NDT) methods such as magnetic particle inspection (MPI) or dye penetrant inspection (DPI). Document the location, size, and extent of the cracks.

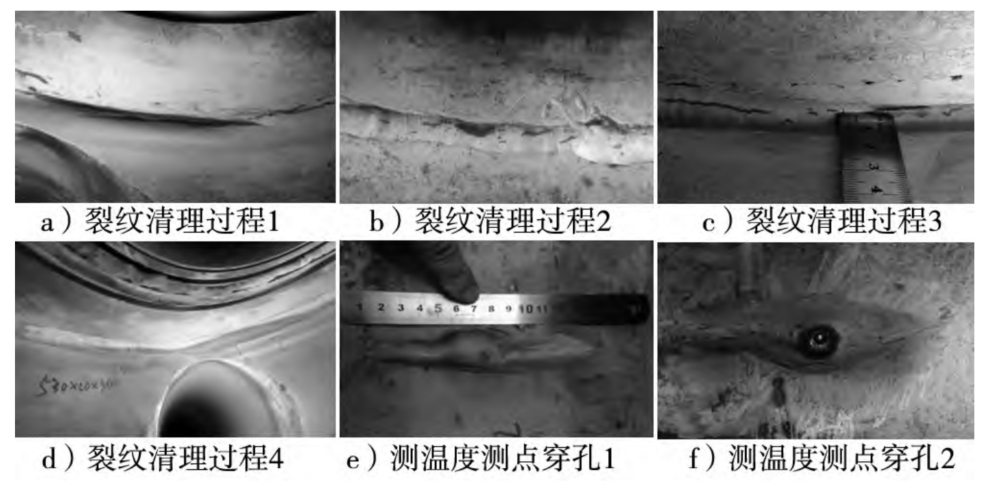

5.2 Crack Removal

- Grinding and Milling: Use abrasive grinding wheels and milling cutters to remove the cracked material, ensuring that all visible cracks are eliminated.

- Re-inspection: Repeat the NDT inspection to confirm the complete removal of cracks and identify any new defects that may have been exposed during the removal process.

5.3 Preparation of Weld Joints

- Joint Preparation: Machine the weld joints to ensure a smooth, even surface suitable for welding. Use appropriate joint geometries to minimize stress concentrations.

- Cleaning: Clean the weld joints thoroughly to remove any oil, grease, rust, or other contaminants that could compromise the weld quality.

5.4 Welding

- Preheating: Preheat the weld area to a temperature range of 80-100°C to minimize the risk of cracking during welding.

- Welding Parameters: Set the welding parameters (current, voltage, welding speed) according to the manufacturer’s recommendations for ENiCrMo-3 welding consumables.

- Welding Technique: Use the gas tungsten arc welding (GTAW) process with a pulsed current to control the heat input and minimize distortion.

- Interpass Temperature Control: Maintain the interpass temperature within the recommended range to prevent overheating and cracking.

- Stress Relief: Use mechanical stress relief techniques such as hammer peening to reduce residual stresses in the weld area.

5.5 Post-Weld Treatment

- Cooling: Allow the weldment to cool slowly to room temperature to minimize the risk of cracking due to thermal stresses.

- Post-Weld Inspection: Conduct a thorough inspection of the weld area using NDT methods to identify any weld defects or new cracks.

- Final Inspection: Verify the dimensional accuracy and functionality of the repaired valves before reinstallation.

6. Quality Control and Assurance

Quality control and assurance measures were implemented throughout the repair process to ensure the highest standards of workmanship and reliability. The following measures were taken:

- Documentation: Maintain detailed records of all steps in the repair process, including inspection results, welding parameters, and post-weld inspection results.

- Traceability: Ensure traceability of all materials and consumables used in the repair process.

- Personnel Qualification: Ensure that all personnel involved in the repair process are properly qualified and trained for the tasks they perform.

- Independent Inspection: Conduct independent inspections at critical stages of the repair process to verify compliance with specifications and standards.

7. Results and Discussion

After successful completion of the repair process, the repaired valves were subjected to a series of tests and inspections to evaluate their structural integrity and functionality. The following observations were made:

- Visual Inspection: The repaired areas showed a smooth, even weld surface with no visible defects or irregularities.

- NDT Inspection: Non-destructive testing confirmed the absence of any cracks or other weld defects in the repaired areas.

- Mechanical Testing: Tensile testing and impact testing were performed on samples cut from the repaired areas. The test results showed that the mechanical properties of the repaired material were comparable to those of the base material.

- Service Performance: The repaired valves were reinstalled and monitored during operation. No issues related to the repaired areas were reported during the monitoring period.

8. Conclusion

The successful repair of crack defects in ZG15Cr1Mo1V steel castings for high-pressure combined main steam valves demonstrates the feasibility and effectiveness of using ENiCrMo-3 nickel-based welding consumables and appropriate welding techniques. The repair process, which included crack removal, weld joint preparation, welding, and post-weld treatment, resulted in a high-quality repair that restored the structural integrity and functionality of the valves. The quality control and assurance measures implemented throughout the repair process ensured compliance with specifications and standards, providing confidence in the reliability of the repaired components.

The experience gained from this repair project can serve as a valuable reference for similar steel casting repair scenarios, particularly in critical applications where reliability and durability are paramount. Further research into the long-term performance of repaired steel castings under service conditions can provide additional insights into the effectiveness of different repair techniques and materials.