1. Casting Structure and Requirements

| Specification | Details |

|---|---|

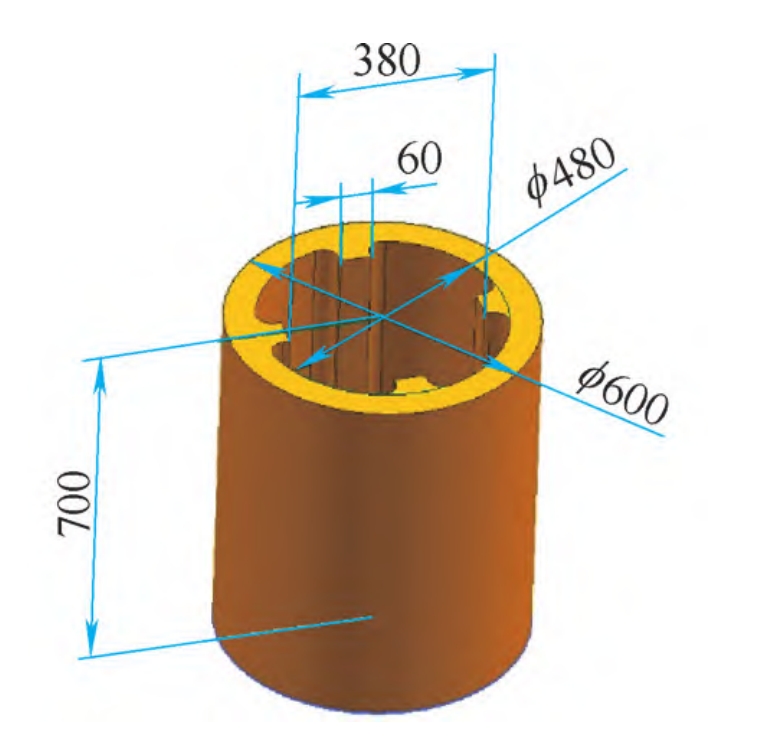

| Structure | Typical tubular structure, outer diameter 600mm, inner diameter 480mm, height 700mm, with 4 T – shaped bosses inside |

| Weight | 190kg |

| Material | ZL205A aluminum alloy |

| Quality Standard | GB/T 9438 – 2013, no shrinkage, porosity, cracks, or pores on internal and external surfaces after machining |

2. Previous Trial Casting Process

2.1 Molding Method

| Molding | Details |

|---|---|

| Pouring Method | Gravity pouring, bottom gating |

| Resin Sand Molding | Upper, middle, and lower three – box process |

2.2 Gating System Design

| Pouring System Component | Specification |

|---|---|

| Straight Runner | 1 conical, bottom diameter 30mm, cross – sectional area 7cm² |

| Cross Runner | 1 annular, trapezoidal cross – section, area 8.4cm² |

| Ingate | 4 trapezoidal, total cross – sectional area 14cm², area ratio 1:1.2:1.7 (straight:cross:ingate) |

| Risers | 4 top risers, size 280mm×60mm×100mm for T – shaped boss compensation |

2.3 Aluminum Ingot Melting and Pouring

| Process | Details |

|---|---|

| Raw Material | ZL205A aluminum ingot |

| Melting | Surface cleaning, compound multi – element refining agent, nitrogen stirring for dehydrogenation |

| Pouring Temperature | 710°C, pouring time 1.5 – 2min |

2.4 Previous Trial Casting Quality

| Defect Detection | Results |

|---|---|

| X – ray Detection | Shrinkage and porosity defects in multiple internal locations, larger in T – shaped boss area |

| Machining | More obvious internal defects, large – area shrinkage porosity on machined surface |

| Defect Distribution | Upper (riser end) and lower (gate end) regions, with different shrinkage areas in each zone |

2.5 Casting Defect Cause Analysis

| Cause | Explanation |

|---|---|

| Pouring Method | Bottom gating causes temperature gradient opposite to sequential solidification, blocking compensation in middle and lower parts, leading to more severe shrinkage porosity |

| Material Properties | Wide solidification range (544 – 633°C), paste – like solidification, poor casting performance, and blocked compensation channels, prone to shrinkage defects |

| Gating System Design | Simple design, limited riser compensation ability for high – height casting, lack of compensation system in other parts, resulting in shrinkage porosity |

3. Process Improvement

3.1 Improved Gating System Design

| Pouring System Component | Specification |

|---|---|

| Straight Runner | 2 conical, diameter 30mm |

| Ingate | 8 trapezoidal |

| Risers | 4 top risers and 8 side risers (section: approximately trapezoidal, 150mm×70mm×90mm, height 700mm, wedge – shaped bottom) |

| Cross Runner | 1 middle rectangular (side length 30mm), connecting side risers |

3.2 Improvement Measures

| Measure | Effect |

|---|---|

| Increase Pouring Components | Shorten pouring time, reduce temperature difference, improve riser compensation ability, and promote simultaneous solidification |

| Add Side Risers | Compensate the whole casting, with wedge – shaped bottom for better compensation |

| Middle Cross Runner | Equalize aluminum liquid temperature, ensure top – down temperature gradient, and improve casting compensation ability |

| Top Riser Re – pouring | Ensure highest temperature of top riser for better compensation |

4. Effect Verification

| Verification Method | Results |

|---|---|

| X – ray Detection | Shrinkage porosity defects basically eliminated, meeting quality standards |

| Machining | Dense and smooth surface, no obvious shrinkage porosity defects |

5. Conclusion

| Conclusion | Details |

|---|---|

| Defect Solution for Bottom Gating | Increase risers and modify gating system to reduce temperature difference and achieve sequential or simultaneous solidification |

| Current Method Evaluation | Low process yield, high cleaning workload and cost, need for further optimization |