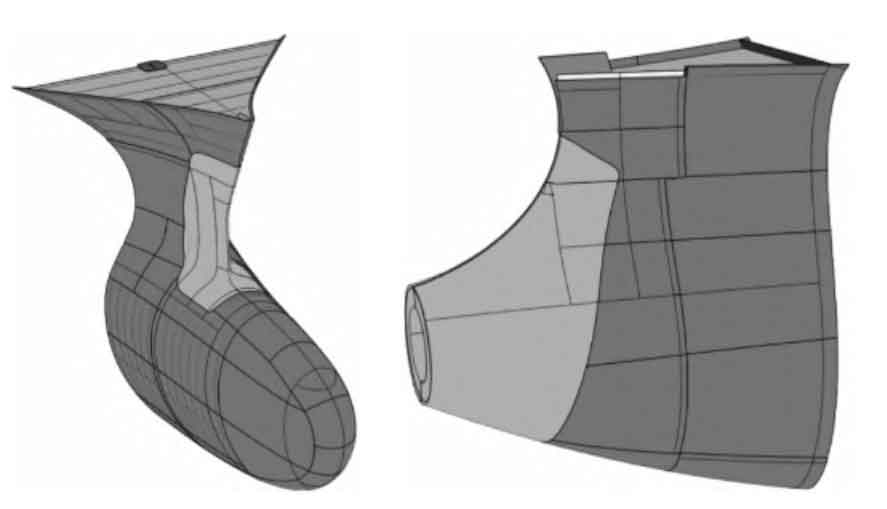

By conducting 3D modeling design on the steel castings of the bow column of a 13000t heavy lifting vessel, the drawbacks of traditional 2D design of steel castings, such as single perspective and overlapping lines, have been overcome. The external structure of the ship’s steel castings is expressed more intuitively, and the difficulty of construction is reduced. At the same time, through three-dimensional modeling and design of steel castings, collaborative design between ship steel castings and ship structure can be achieved in design management, avoiding problems such as excessive docking errors and significant weight estimation errors caused by the complex structure of the outer plate docking area, and improving the efficiency of the overall design of ship structures. The use of three-dimensional modeling to estimate the quality of steel castings can reduce the error caused by traditional methods. For example, the error of the three-dimensional model quality estimation of the bow column of a 13000t heavy crane ship compared to actual results is reduced by more than 10%, which can enhance the initiative of enterprises in steel casting construction quotation and commissioned construction negotiation, and save construction costs.

The CATIA three-dimensional design modeling method for steel castings can be used to complete the design and quality estimation of ship steel castings, and can also achieve collaborative design between ship structure and ship steel castings, effectively improving the accuracy and intuitive expression of ship structure and steel casting design, which has certain engineering significance and practical value.