1. Ordinary white cast iron

Ordinary white cast iron can only be used in as cast state, and carbon atoms mainly exist in the form of Fe3C. The matrix structure of as cast ordinary white cast iron is pearlite or ferrite, i.e. ledeburite structure, and the hardness is about 500 Hb. However, due to the continuous network distribution of carbides along the pearlite grain boundary, large cleavage of the matrix, high brittleness, low hardness and poor wear resistance, it can only be used in the case of small impact load. Because the hardness of carbide m3c (HV 900 ~ 1100) is higher than that of martensite (HV 550 ~ 950), the wear resistance of ordinary white cast iron is better than that of high manganese steel and low alloy steel under low load conditions.

2. Nickel hard cast iron

Nickel hard cast iron is used in the as cast state. The matrix structure is a mixture of austenite and martensite. The eutectic cementite m3c is distributed in a network along the austenite grain boundary, with high brittleness and hardness of 550 ~ 650 Hb. It is only suitable for manufacturing castings that do not bear large impact load.

3. Chromium cast iron

Chromium cast iron can be divided into low chromium cast iron, medium chromium cast iron and high chromium cast iron according to chromium content. Low chromium cast iron (CR ≤ 5.0 wt.%) adopts as cast stress relief treatment or high-temperature air quenching + low-temperature tempering treatment. The microstructure after heat treatment is pearlite + eutectic carbide (Fe, Cr) 3C (m3c), or martensite + eutectic carbide m3c + residual austenite. The hardness after heat treatment is 50 ~ 62 HRC, the toughness of the material is not good, and brittle fracture is easy to occur. Low chromium cast iron is usually used in industrial applications with low stress and low hardness requirements.

The chromium content of medium chromium cast iron (CR 5.0% – 10.0%) is treated by high temperature air quenching + low temperature tempering. The matrix structure is pearlite or martensite + austenite, and the eutectic carbide is M7C3 + a small amount of m3c. The hardness after heat treatment is 55 ~ 65 HRC, which has certain toughness and wear resistance.

The as cast structure of high chromium cast iron (CR 12.0% ~ 28.0%, C 2.4% ~ 3.6%, Cr / C ratio not less than 3.5) is austenite + eutectic carbide (Fe, Cr) 7C3 (M7C3). The microstructure in heat treatment state is martensite + eutectic carbide M7C3 + secondary carbide + a small amount of retained austenite. After heat treatment, it can reach high hardness value, i.e. 60 ~ 67 HRC.

Various structures cooperate with each other to make high chromium cast iron have high hardness and excellent wear resistance. However, wear-resistant cast iron still has some disadvantages, such as high brittleness, poor plasticity, easy damage and fracture under strong impact stress.

4. Current standards for wear resistant cast iron

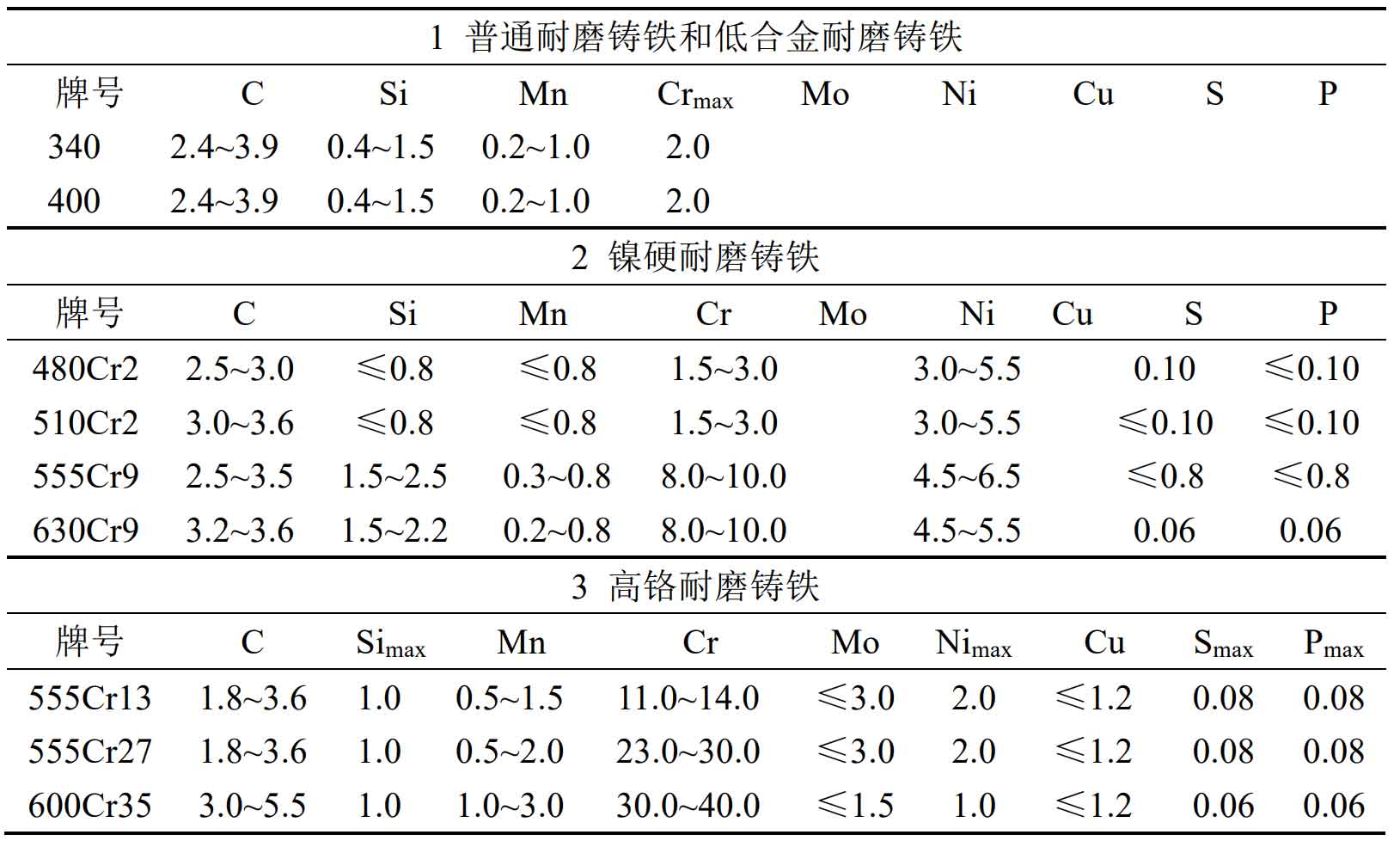

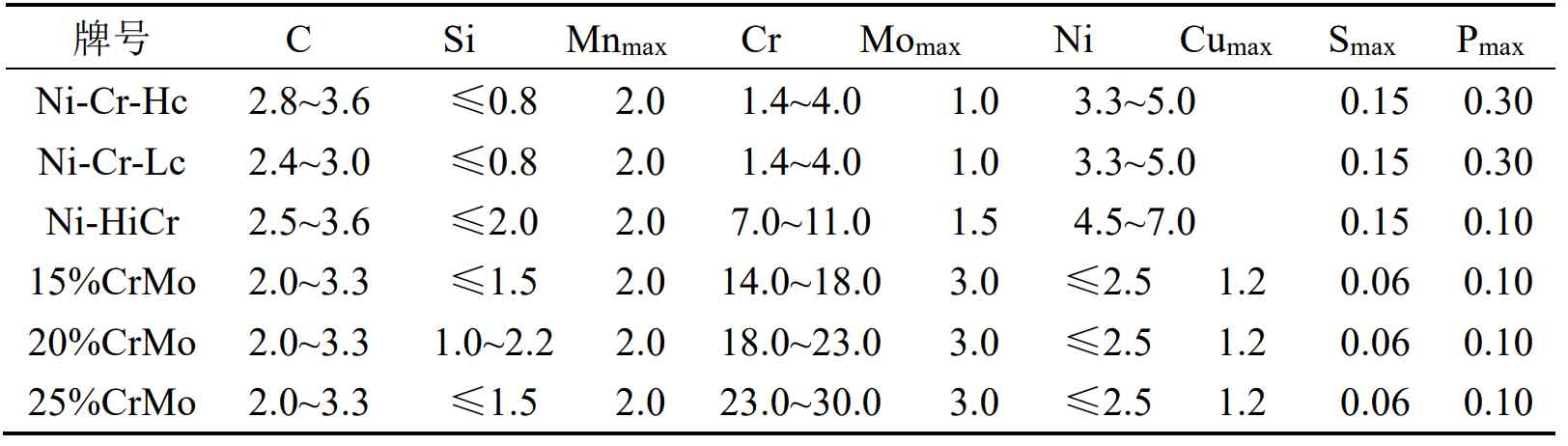

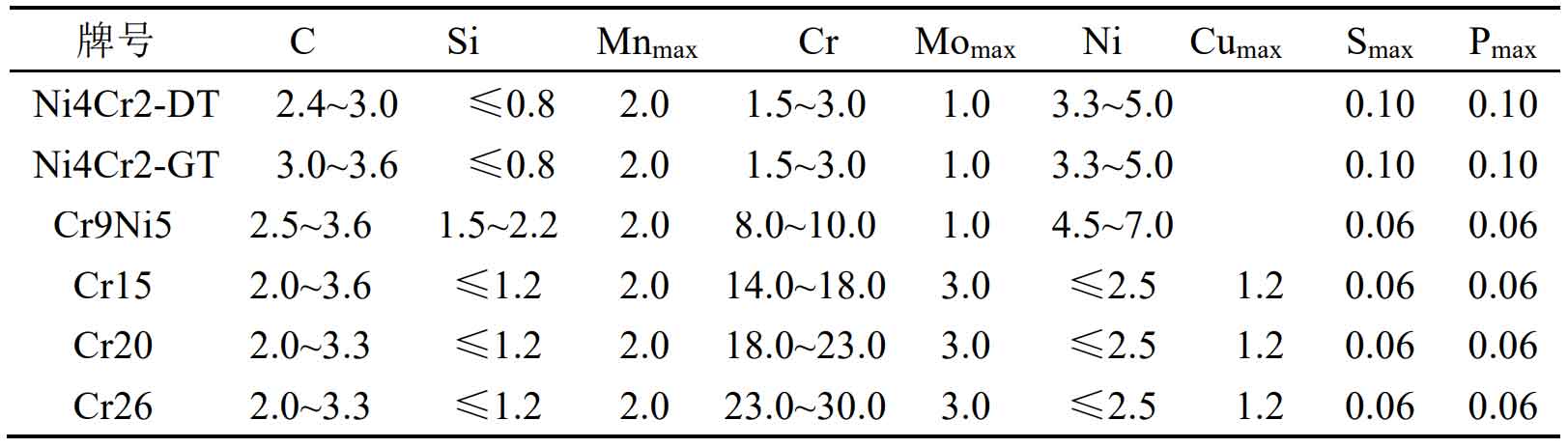

Wear resistant cast iron is mainly characterized by high hardness, high wear resistance and low toughness. It is a brittle material. Other properties such as general tensile strength, low impact toughness, good corrosion resistance, poor heat resistance and poor machinability. The current standard of the international organization for standardization is ISO 21988: 2006. The main chemical composition is shown in Table 1. 340 is ordinary wear-resistant cast iron, 510 CR2 (4.0% Ni, 2.0% Cr, eutectic carbide m3c) and 555 CR9 (5% Ni, 9.0% Cr, eutectic carbide m3c + M7C3) are nickel hard cast iron, and the rest are high chromium wear-resistant cast iron. The current standard ASTM a532m-2010 (2014) for wear-resistant cast iron in the United States is shown in Table 2. The current standard for wear-resistant cast iron in China is GB / T 8263-2010. The main brands and chemical compositions are shown in Table 3.