The numerical simulation results of the solidification process of the improved lost foam casting turbine rear exhaust pipe are analyzed. Through the numerical simulation of lost foam casting after the improvement of the turbine rear exhaust pipe process, the analysis process of mold filling is not detailed. Here, the solidification process and casting defects are mainly displayed and analyzed.

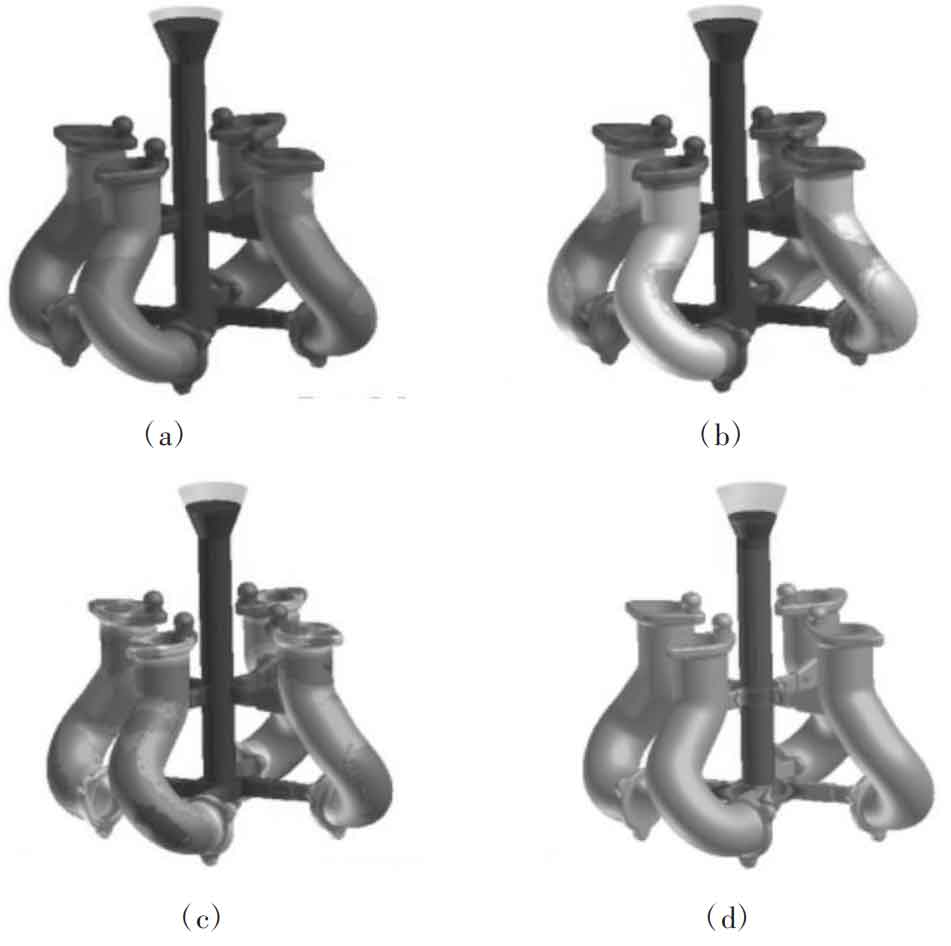

The figure shows the solidification state and solidification percentage of the exhaust pipe after the turbine at different times, in which figures (a ~ d) show the solidification state when step = 5600, step = 5610, step = 5640 and step = 5850.

After the improvement of lost foam casting process of turbine rear exhaust pipe, by observing its solidification state and solidification percentage at different times, it can be seen that there is no insufficient pouring at the top of the casting. On the whole, the feeding channel of the casting is basically unblocked during solidification, the last liquid stays in the gating system, and the riser can effectively play the role of feeding.