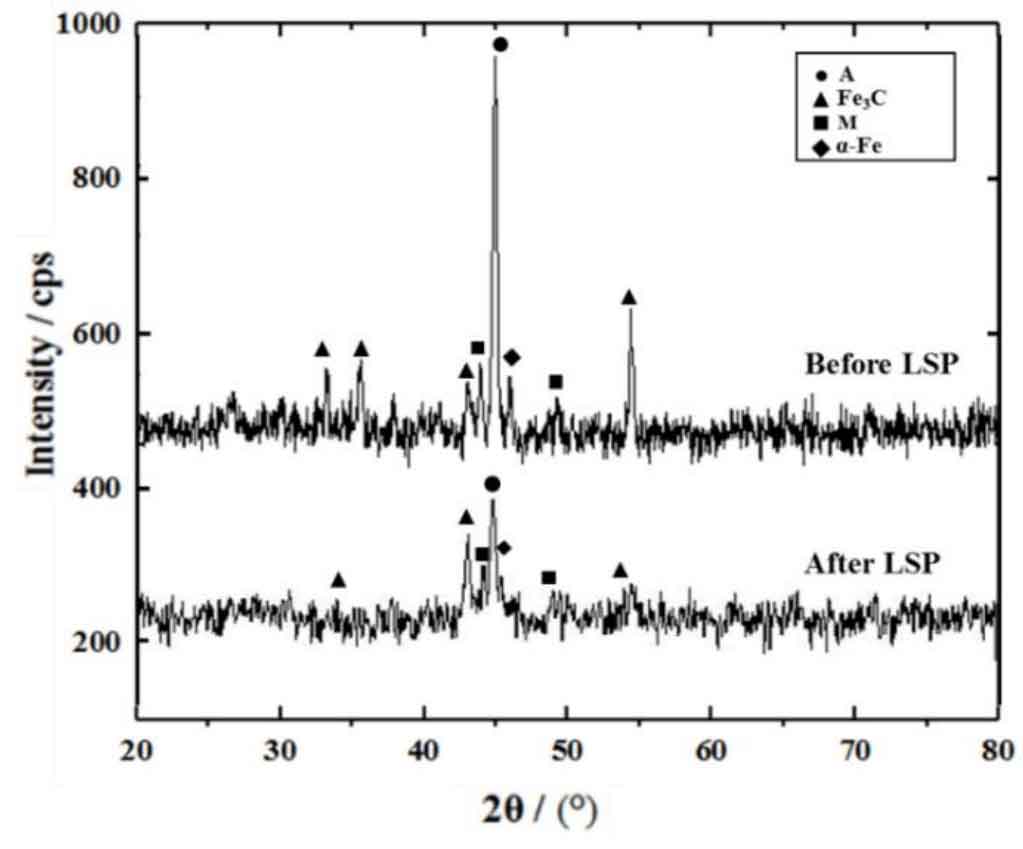

The X-ray diagram of the surface of gray cast iron sample after laser shock melting is as follows. It can be seen from the figure that before and after laser shock, the microstructure of gray cast iron melting layer is mainly composed of austenite and Fe3C. The surface of gray cast iron melting layer is mainly affected by the shock wave induced by laser, which will not produce new phases in the gray cast iron melting layer.

Compared with the XRD diagram of the fused layer of gray cast iron before laser shock, the intensity of the diffraction peak of austenite is significantly reduced after laser shock, because after laser shock, the austenite structure is refined and part of cementite structure is decomposed. The position of the diffraction peak of Fe3C shifts, and the width of the half peak becomes larger. It is considered that the laser shock leads to the deformation and refinement of the cementite of gray cast iron, and changes its lattice shape.