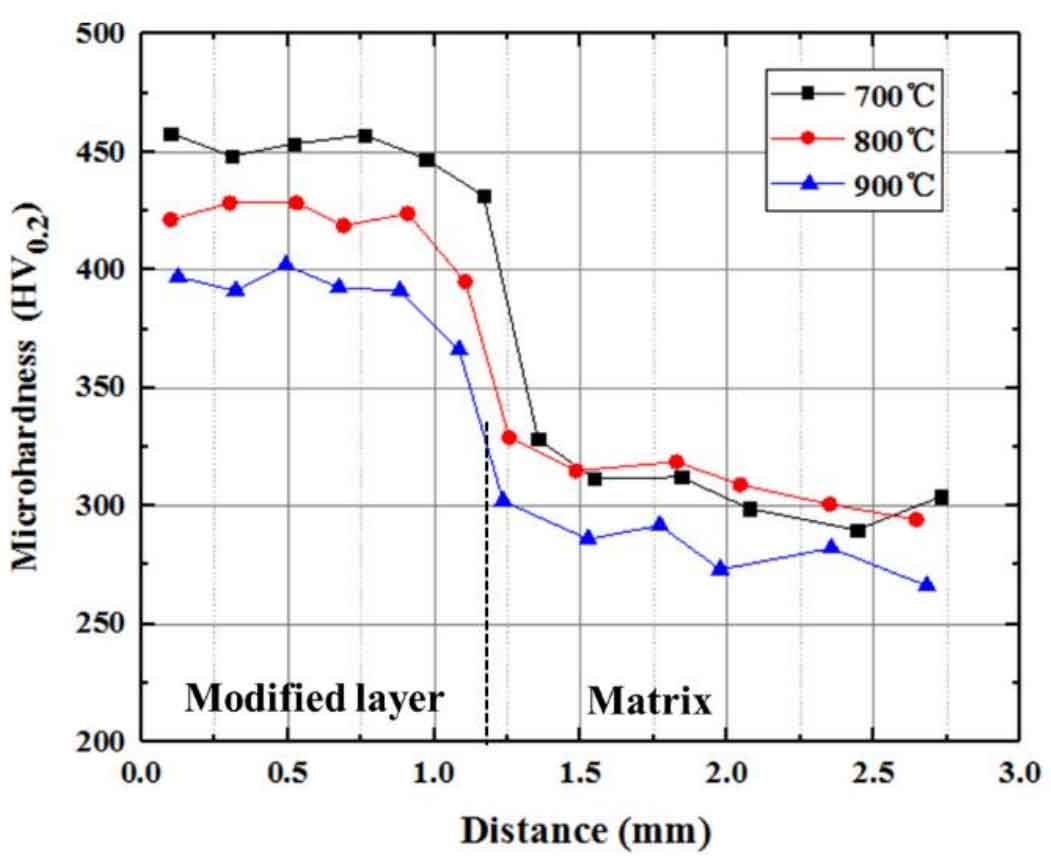

The hardness changes of gray cast iron after laser melting and impact at different annealing temperatures are shown in the figure. When the annealing temperature is 700 ℃, the average hardness of the modified layer of gray cast iron is 448 hv0 2. Compared with the fused layer before annealing, the surface hardness is reduced by half. When the annealing temperature is heated to 800 ℃, the maximum hardness of the modified layer of gray cast iron is 422 hv0 About 2. With the increase of annealing temperature, the hardness of gray cast iron modified layer decreases gradually. The higher the annealing temperature, the more sufficient cementite decomposition, and the more obvious the decrease of hardness of gray cast iron modified layer.

After annealing, the hardness of the modified layer of gray cast iron is still higher than the average hardness of the matrix. During graphite annealing, the matrix structure also has ferrite transformation, and the average hardness of the matrix is 260 hv0 2。 After graphite annealing of gray cast iron, the cementite structure in the modified layer decomposes, the ferrite structure increases, the ferrite grain becomes larger, and the hardness of the melting layer decreases. However, after annealing, the graphite precipitated from the modified layer of gray cast iron changes into fine spherical or flocculent, which reduces the damage to the continuity of the matrix and improves the performance of the modified layer. Fine granular pearlite is dispersed on the ferrite matrix, which improves the strength of the ferrite matrix.