1. Analysis of sand casting process

The material of sand mold casting rotary disc is HT250, which is a medium-sized complex casting produced in small batch. It has high quality requirements for dovetail guide sliding surface and screw hole surface. Due to the advantages of high dimensional accuracy, smooth surface and dense structure of sand mold castings obtained by furan resin self hardening sand molding, furan resin self hardening sand is selected as the molding material of sand mold and sand core, and alcohol-based coating is used for manual molding and core making. The maximum nominal size of the sand mold casting is 1040 mm, so the dimensional tolerance of the sand mold casting is ct11; The quality tolerance grade of sand casting is mt10; The weight tolerance of sand mold castings is ± 4%; The size of the rotary table in sand mold casting is general, and the shrinkage rate during solidification is not greater than its free shrinkage rate. Considering the obstruction, the shrinkage rate is taken as 0.9%; According to the principle of single piece small batch production, considering the modeling efficiency in the design, all threaded holes are not cast, and the later drilling processing is adopted, and the later cutting of long plane dovetail groove is completed.

2. Selection of pouring position and determination of parting surface

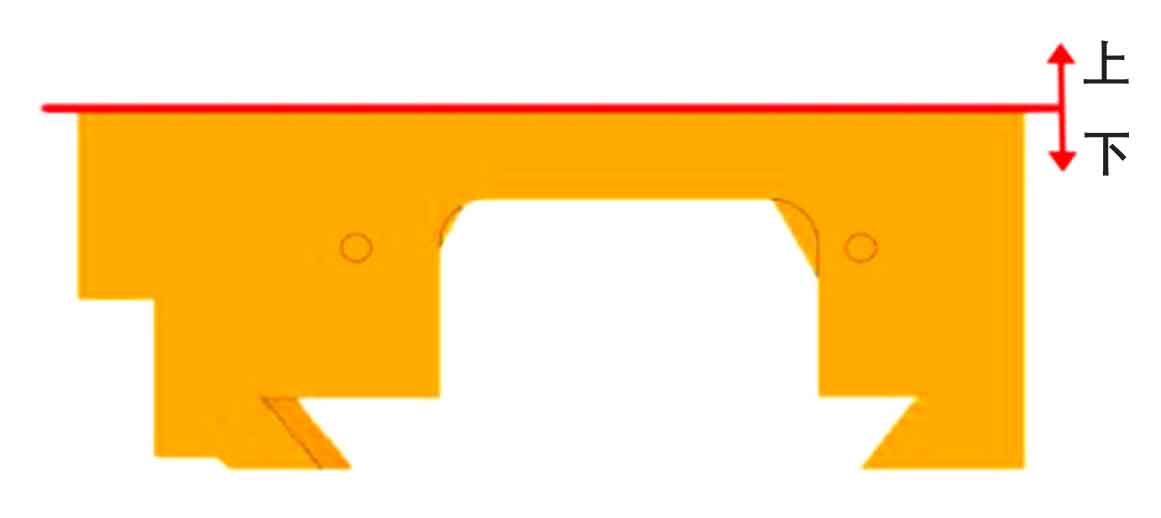

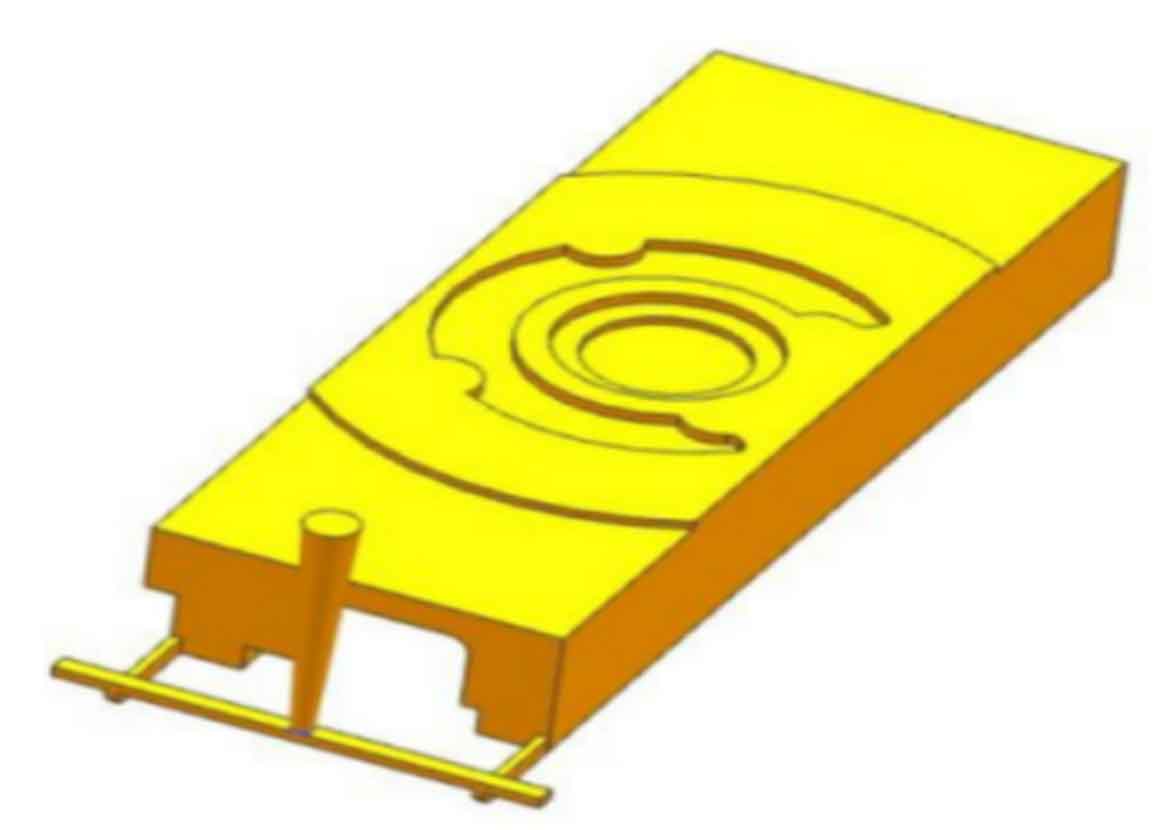

The pouring position of sand mold casting is shown in the figure. The dovetail sliding guide surface is downward and the large plane is upward. The large surface of sand mold casting is above. The thin wall and complex structure can make full use of gravity to strengthen the filling, so as to ensure the filling and crystallization quality of slender dovetail sliding guide surface. It should be noted that slag inclusion and other defects will float on the top plane, so the machining allowance needs to be increased for later machining removal. The advantages of this pouring position are that the upper box is thin and light, easy to close and shape, which is conducive to the placement and fixation of sand core, and also conducive to ensuring the filling and crystallization quality of dovetail sliding surface at the bottom. Due to the good rigidity of furan resin sand and high sand mold strength in the early stage of sand mold casting, the graphitization expansion of cast iron solidification process is used to effectively eliminate the defects of shrinkage cavity and shrinkage porosity, so as to realize the less riser and no riser casting of gray cast iron and reduce the process complexity. In order to ensure the filling quality of the top large plane, inclined pouring is adopted. The machining allowance grade is f ~ h. considering the convenience of machining, the specific dimensions of each machining quantity are determined as follows: the side of the guide rail is 5 mm, the end face is 8 mm, the inclined pouring top and large plane boss are 10 mm, and the rest machining surfaces are 5 mm.

The parting surface is selected at the largest section of the casting to facilitate mold lifting, simplify modeling and template structure and manufacturing, ensure the dimensional accuracy of sand mold casting, and facilitate core lowering and box closing.

3. Design of gating system for sand mold casting

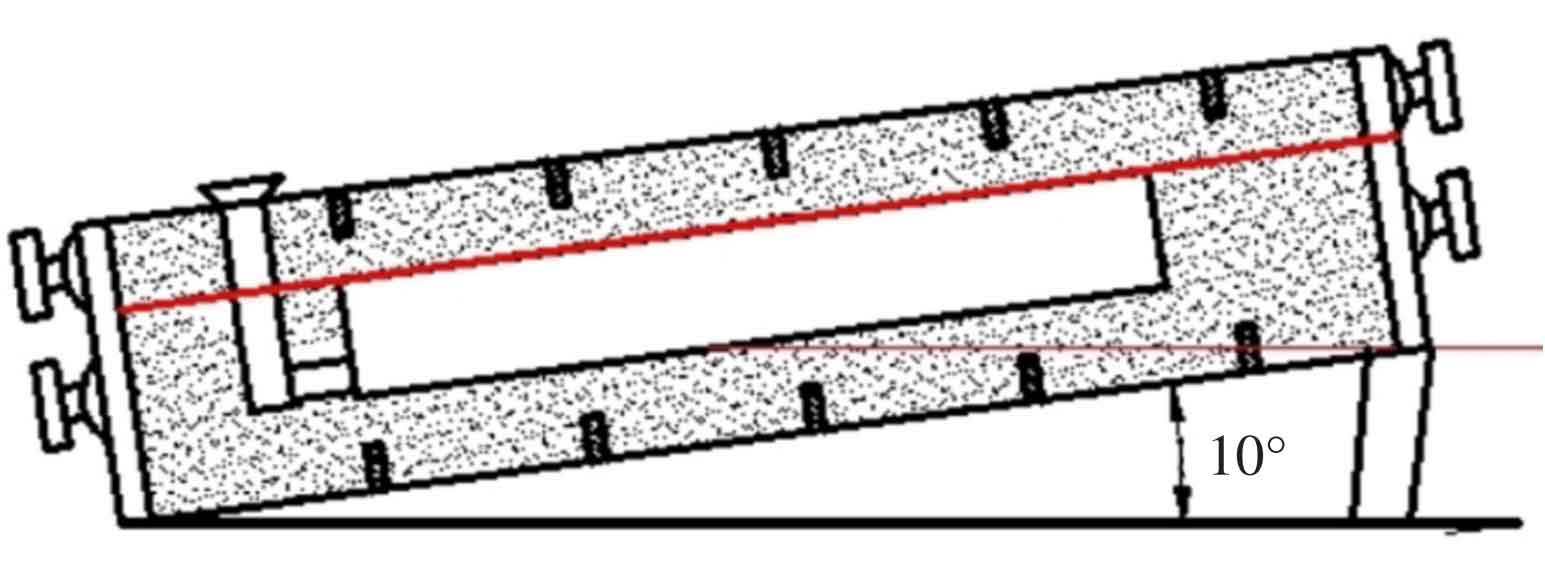

According to the production experience and the structural characteristics of sand mold casting combined with this design, as shown in Figure 3, the inner sprue is set at the outer surface of the bottom of one end of the casting, which has small filling resistance and stable filling; After the mold is closed, one end of the mold is lifted to a certain height, and the inclined pouring is carried out by using the self weight pressure principle of liquid metal, as shown in Figure 4. At this time, the molten iron forms a pressure gradient in the mold cavity, and the maximum value is reached when the highest inclined part is filled with molten iron. This kind of pressure plays a decisive role in minimizing the porosity of iron castings. At the same time, it can solidify the molten iron at the same time and reduce the tendency of hot cracking. The gating system of sand mold casting is set at the end face to be machined on the outer surface, which not only facilitates the removal of the gating system, but also ensures the appearance quality of sand mold casting. Bottom injection filling is adopted, with small and stable resistance and short flow channel, which is convenient for modeling.