1. Numerical simulation of bottom pouring inclined gating system in sand mold casting

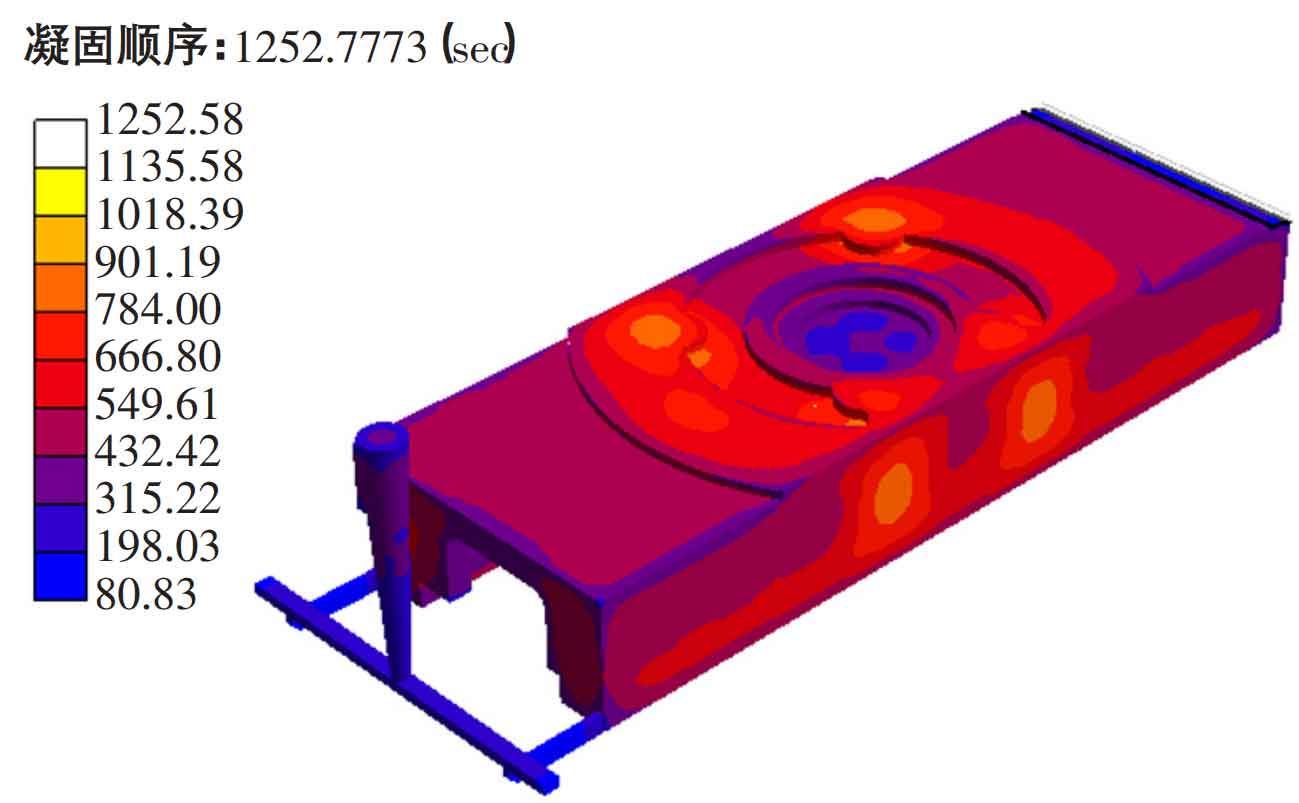

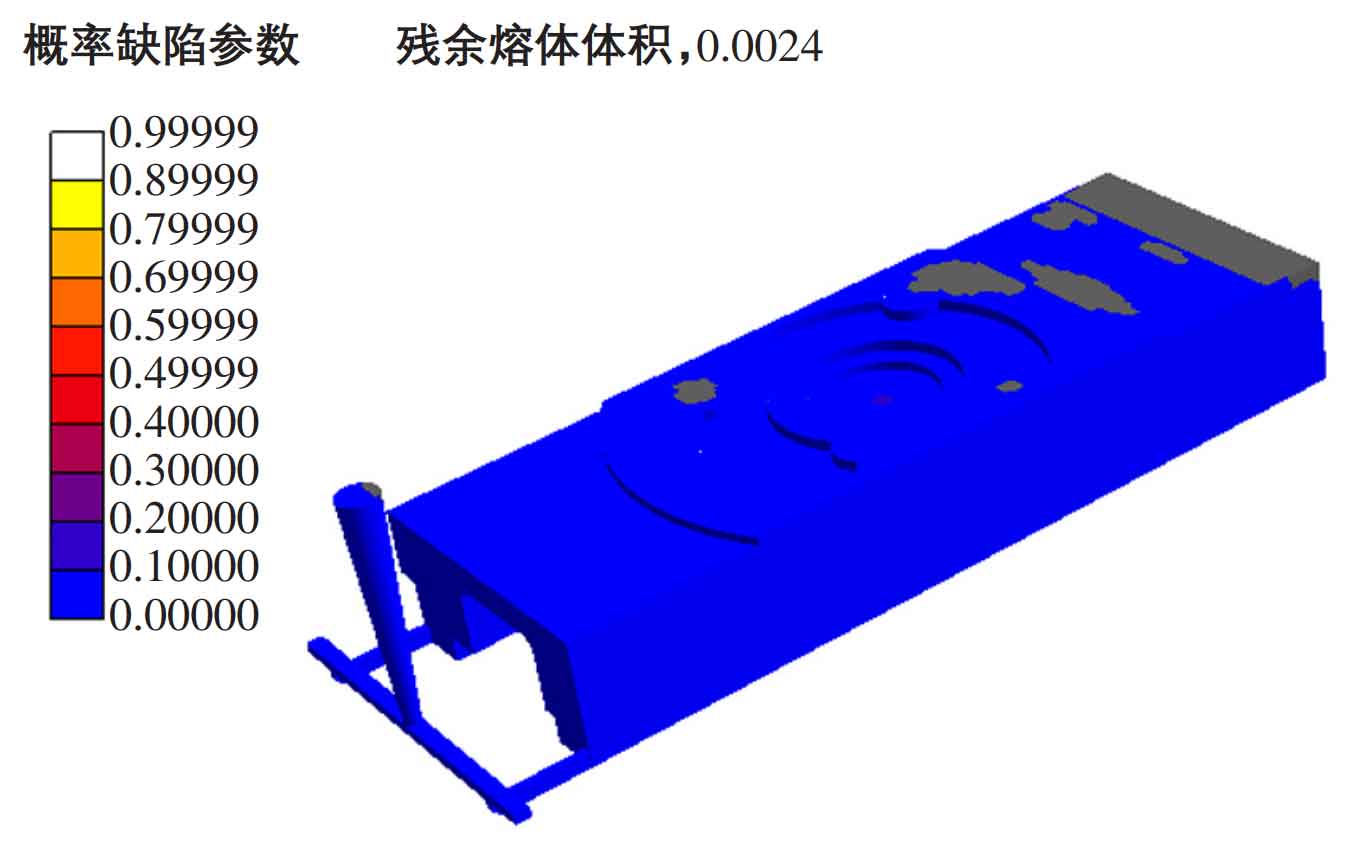

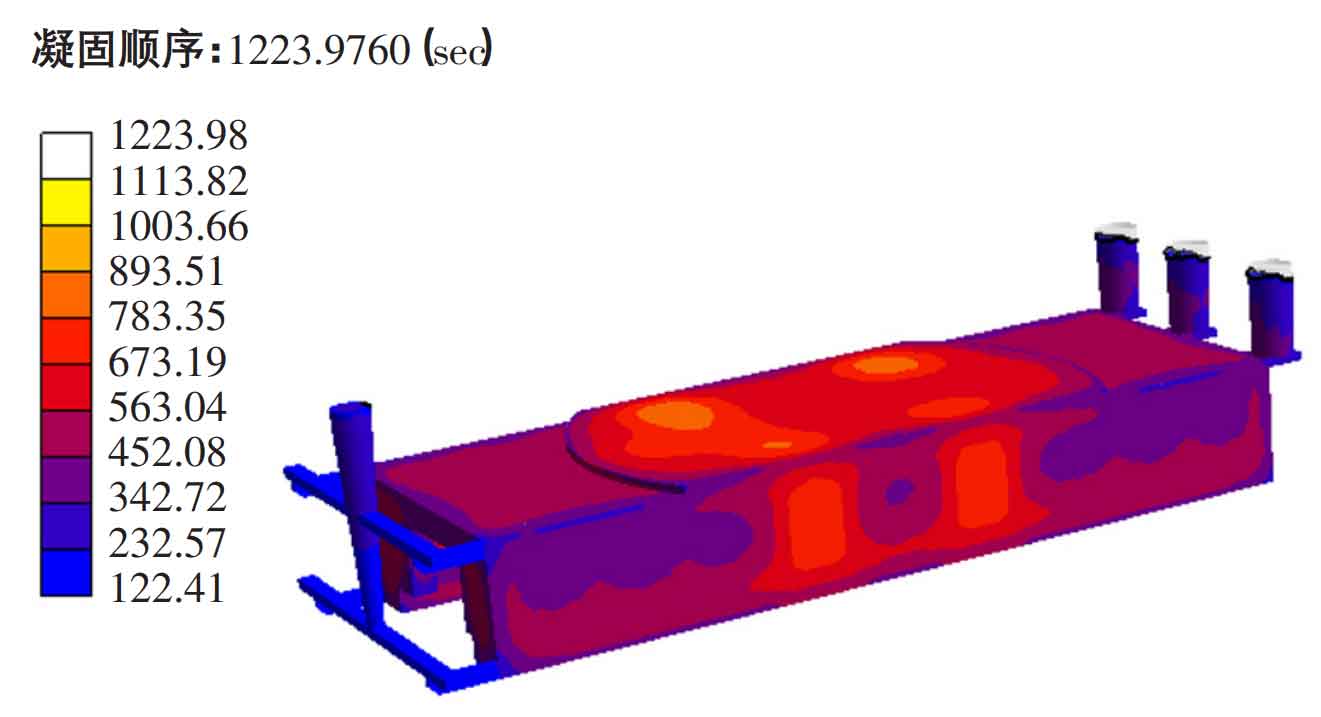

AnyCasting is used for numerical and simulation analysis. The simulation results are shown in Figure 1 and Figure 2. From the perspective of the bottom pouring inclined pouring system scheme, the filling effect of this scheme is the same as that of the envisaged inclined pouring. The whole filling process is relatively stable, and no splashing and air entrainment of liquid metal are found. The overall filling effect is good. From the solidification sequence, hot spots appear in the wall thickness of sand mold castings, so the scheme of bottom injection inclined gating system needs to be further optimized.

2. Process optimization of bottom pouring inclined gating system in sand mold casting

It can be seen from Figure 2 that the defects produced by this scheme are mainly concentrated at the highest place of pouring position, and the process optimization is mainly divided into two aspects: first, eliminate the shrinkage defects of sand mold castings by setting risers; The second is to control the solidification sequence of sand mold castings in the mold cavity during pouring, so as to realize the first solidification of key parts, so as to obtain feeding and eliminate the defects of key parts. The rotary table is a cast iron. It can be seen in Figures 1 and 2 that the solidification of liquid metal is relatively slow at the bottom of the sand mold casting and in the cavity close to the gating system. In order to make the sand mold casting solidify from top to bottom, the design optimization scheme is as follows:

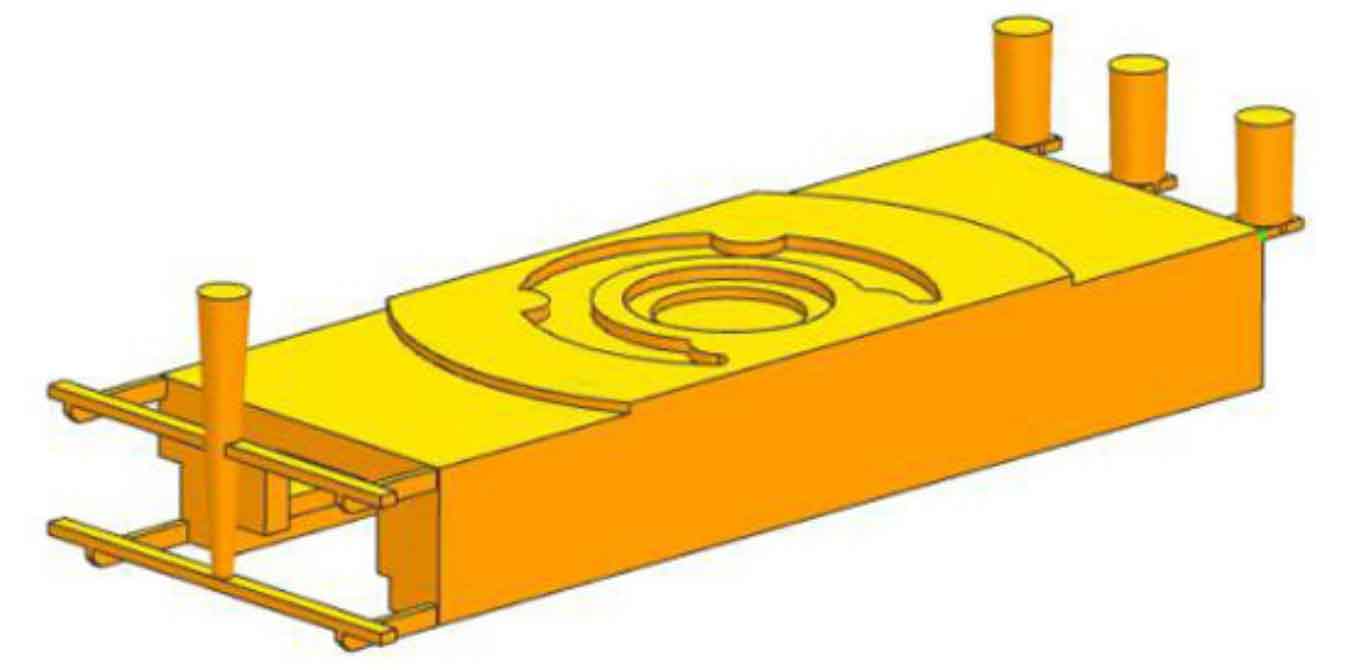

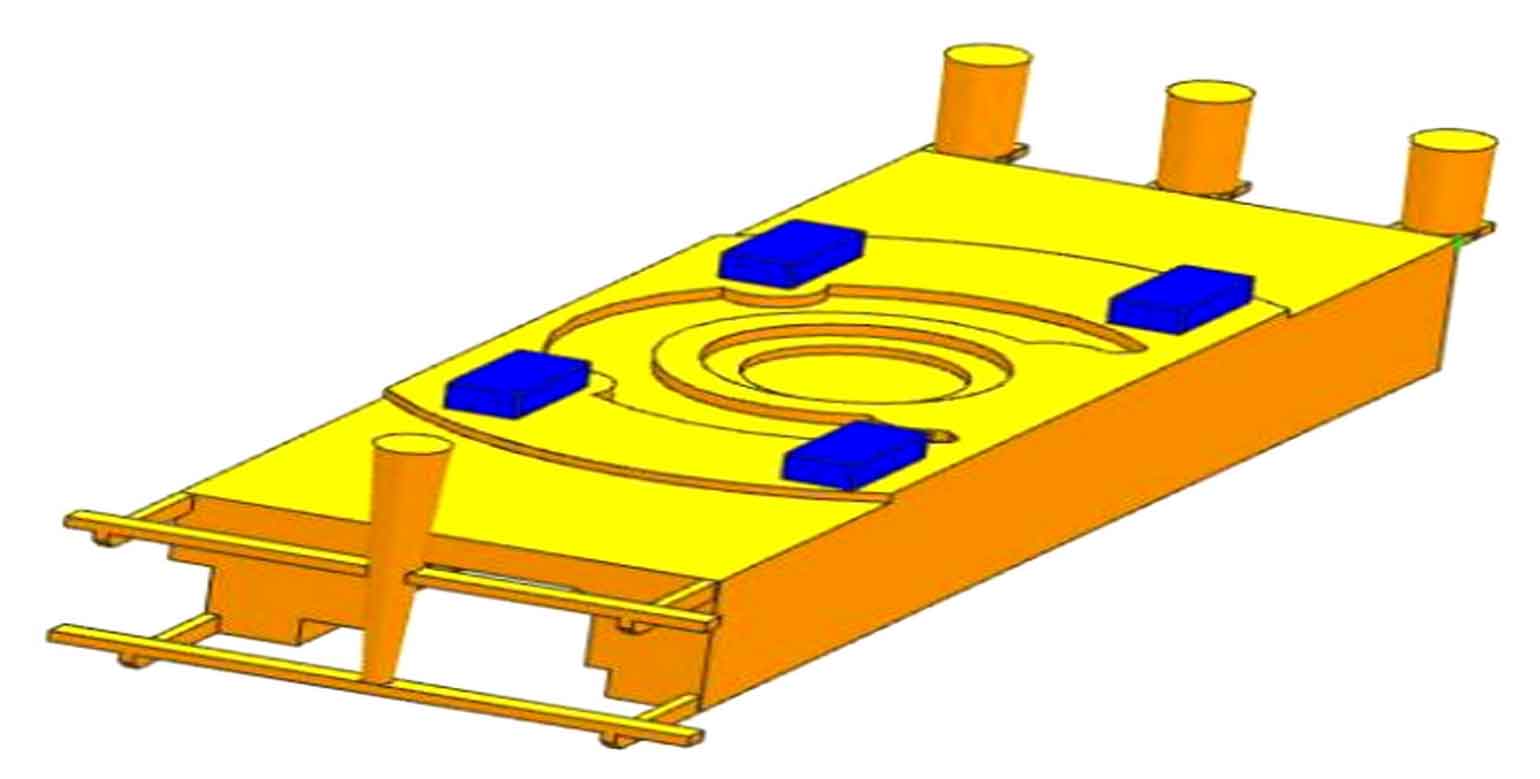

1) The bottom pouring inclined gating system is changed into stepped inclined gating system, as shown in Figure 3. The filling sequence of step pouring is that the liquid metal falling from the sprue first enters the cavity from the bottom, and then when the liquid level rises to the inner sprue of the second layer, all the remaining liquid metal enters the cavity from the inner gate of the second layer. At this time, because there is no new hot liquid metal flowing into the guide rail near the bottom inner sprue, it starts to cool and crystallize first, so as to achieve the first crystallization of the bottom guide rail, reduce the overheating time here, and it is easier to ensure the microstructure and performance here; The solidification sequence of the last crystallization at the top of the right side makes it easier for slag and gas to be discharged from the top of the right side. In addition, the filling resistance of this step pouring is small and stable, the flow channel is short, the use of insert block is also convenient for modeling, and the gate cutting trace is on the end face of the processing surface, which is convenient to remove; The sand core is firmly placed, and the production rate of sand mold castings is also high.

2) The riser is set at the highest place on the right side of the sand mold casting. Considering the difficulty of machine tool processing after the processing of sand mold casting and saving materials, it is finally decided to use three open risers. According to the molding characteristics of gray cast iron, its volume shrinkage is small. The riser is mainly used to discharge the gas in the mold cavity and collect the slag inclusion or oxidized liquid metal at the front of the liquid flow. Therefore, the volume does not need to be too large. The optimized pouring system is shown in Figure 3.

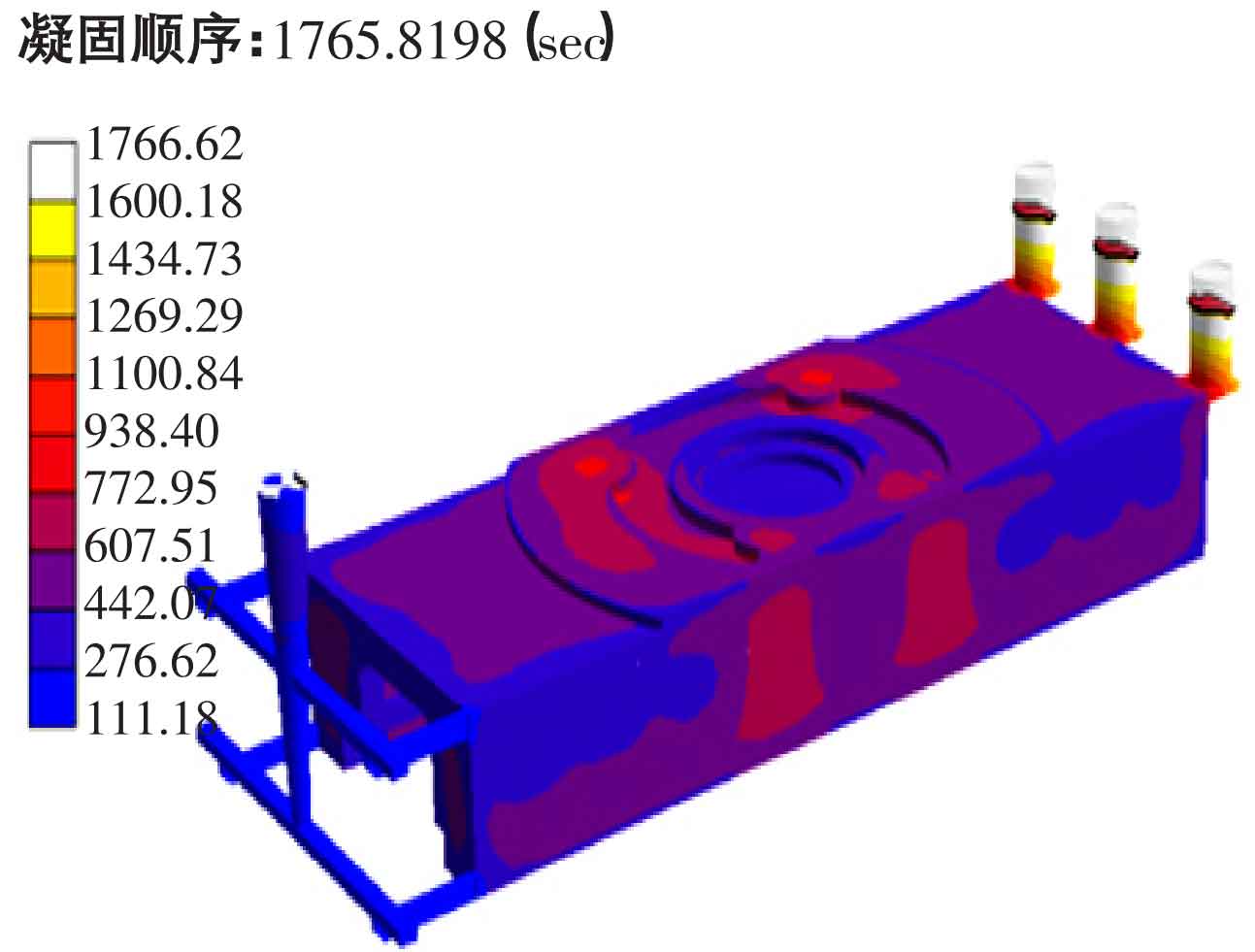

3. Numerical simulation and analysis of the first optimization of sand mold casting

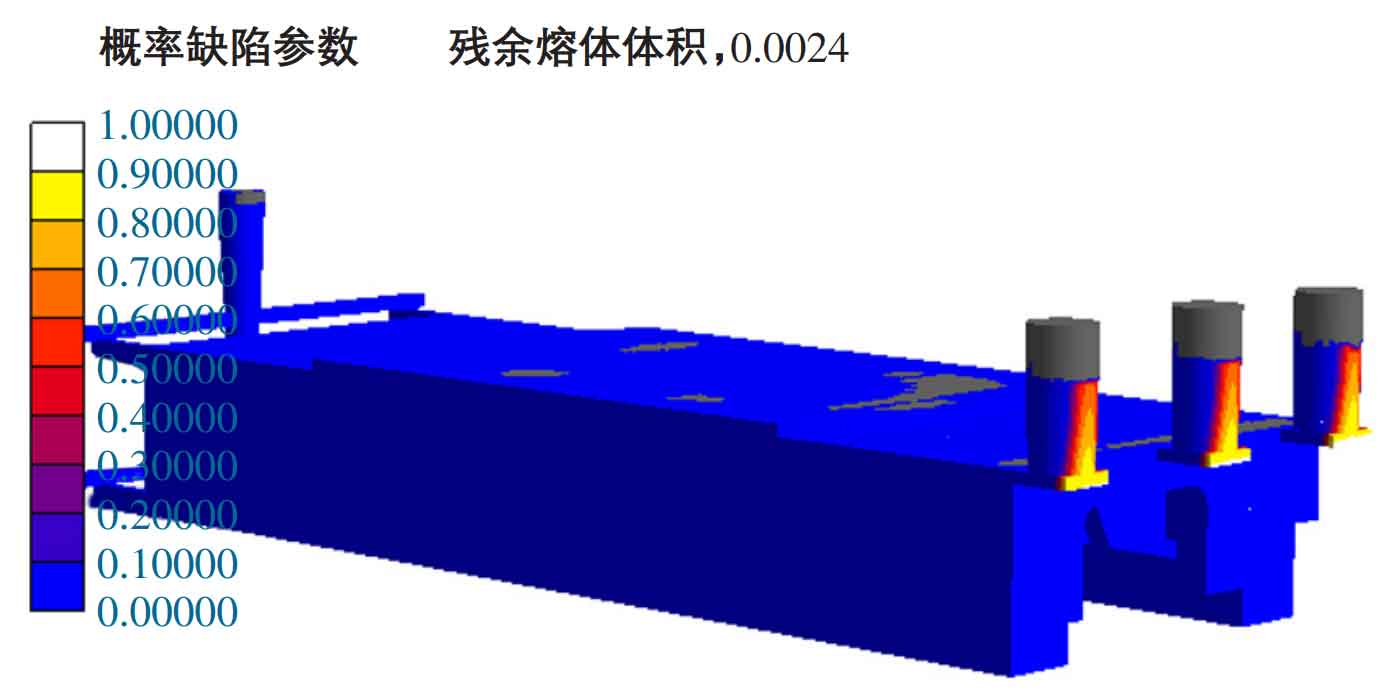

According to the optimization scheme, the solidification sequence of parts is uniform, and the overall defects are concentrated at the riser, which is conducive to ensuring the overall quality of sand mold castings. It is known from Fig. 4 that there is a high probability of hot spots near the screw holes in the thicker part of the sand mold casting, which may produce defects. Therefore, the cold iron is set at this part to make the liquid metal subject to the chilling effect, reduce the formation of defects, refine the grain size and increase the screw hole strength of the subsequent processing of the sand mold casting.

4. Numerical simulation and analysis of the second optimization of sand mold casting

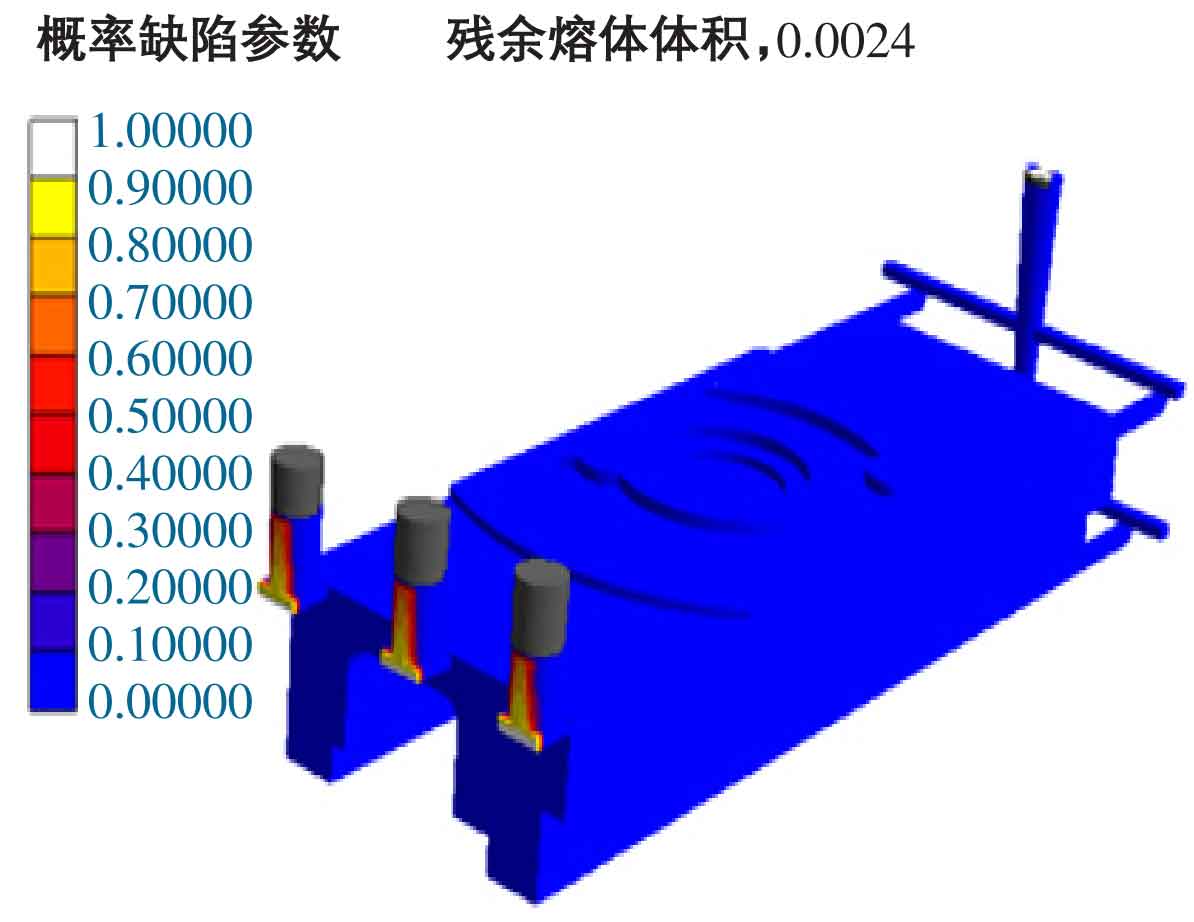

In order to ensure the crystallization quality of the screw hole to be processed near the top hot joint, the cold iron is used for secondary optimization in this optimization. The cold iron is made of cast iron. The placement of the cold iron is shown in Figure 5. The cold iron position is the position of the threaded hole, which can improve the strength of the threaded hole here. The simulation results are shown in Figure 6. According to the simulation results, the occurrence of hot spots has been significantly improved, and there are no obvious defects on the surface of sand mold castings. The shrinkage hot spots are transferred to the riser to meet the quality requirements of sand mold castings.

The three-dimensional model is weighed. The mass of sand mold casting is 174.45 kg, the mass of gating system is 85.25 kg and the mass of riser is 9.8 kg. According to the formula of process yield of sand mold casting:

The technological yield of sand mold casting is 64.73%.