It is inevitable that there are errors in the experiment of heat exchange and temperature measurement in sand mold casting. The main sources of errors include the errors caused by temperature, the errors caused by thermocouple delay effect (sensitivity), the installation position deviation of thermocouple and the error of recording instrument.

(1) Thermocouple error

The error of standard K-type thermocouple in measuring different temperature ranges is different. According to China’s regulations, the allowable temperature measurement error of sand mold casting heat exchange within 0-1100 ℃ is generally ± 2 ~ 4 ℃ or% 0.75T. T represents the measured temperature value of sand mold casting heat exchange.

(2) Delay effect error

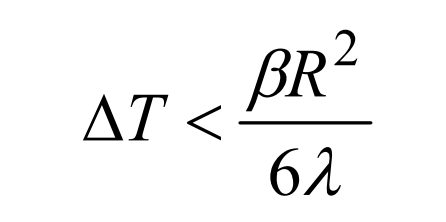

The working principle of contact sand mold casting heat exchange temperature measuring element is to achieve thermal balance between the temperature measuring element and the measured object. The heat transfer needs a certain time to reach the heat balance, which is called delay time. When the temperature field of the casting or mold changes, this delay effect makes the temperature response measured by the thermocouple out of sync with the actual temperature field, which brings errors to the measurement. The thermal response time of the thermocouple for heat exchange temperature measurement in sand mold casting determines the error of the temperature measurement data. The diameter of the measuring end of the thermocouple is the main factor, that is, the thinner the thermocouple wire is, the smaller the diameter of the joint at the measuring end is, the shorter the thermal response time is. The thermocouple produces the maximum heat exchange temperature measurement error of sand mold casting due to the delay effect, which meets the following relationship.

Where, λ Is the thermal conductivity of thermocouple material, in w / (m ∙ K); β Is the change rate of the measured temperature; R is the spherical radius at the end of the welded joint.

(3) Record the error of the instrument

The whole process of sand mold casting heat exchange experiment takes a long time, and the sensitivity of the instrument and sand mold casting heat exchange temperature measuring element will deviate under high temperature for a long time. Some characteristics of the measuring instrument itself will bring some errors to the test results.