The investment casting process of single impeller blade mainly includes several processes: mold material preparation, investment mold manufacturing, cooling, storage and inspection. The specific process is shown in the table below.

| Technological process | Process parameters |

| Investment mold configuration of impeller blade | — |

| Wax melting equipment | Resistance furnace or power frequency sensing wax melting furnace |

| Feeding sequence | First melt the ground wax and Sichuan wax, add polyethylene or EVA in the mixing, then add rosin after full melting, add modified rosin (or 424#) after full melting of rosin, and finally add paraffin and mix evenly |

| Melting temperature | ≤200°C |

| Investment mold manufacturing of impeller blade | — |

| Wax pressing equipment | Manual or semi-automatic heat preservation and wax pressing machine |

| Site temperature | 15∼28°C |

| Mold temperature | 70∼85°C |

| Molding temperature | 20∼30°C |

| Parting agent | Metal pressure molding: transformer oil, methyl silicone oil or 1:1 mixture of Jiuqing and castor oil |

| Injection pressure | 0.3~1.5Mpa |

| Pressure holding time | 1 ∼ 3 minutes |

| Coolant | Water (temperature 16 ∼ 25 ° C) |

| Impeller blade investment cooling | — |

| Cooling time | ≤ 1 hour |

| Storage temperature | 15∼28°C |

| Impeller blade investment mold storage | — |

| Storage method | (not stacking) shall be placed on the special formwork |

| Appearance inspection | 100% inspection is not allowed to have defects such as drape, cold lap, crack, shrinkage, bubble, etc |

| Investment mould inspection of impeller blade | — |

| Measurement inspection | Check the dimension and geometry of blade investment mold with caliper, chuck, template and other special measuring tools |

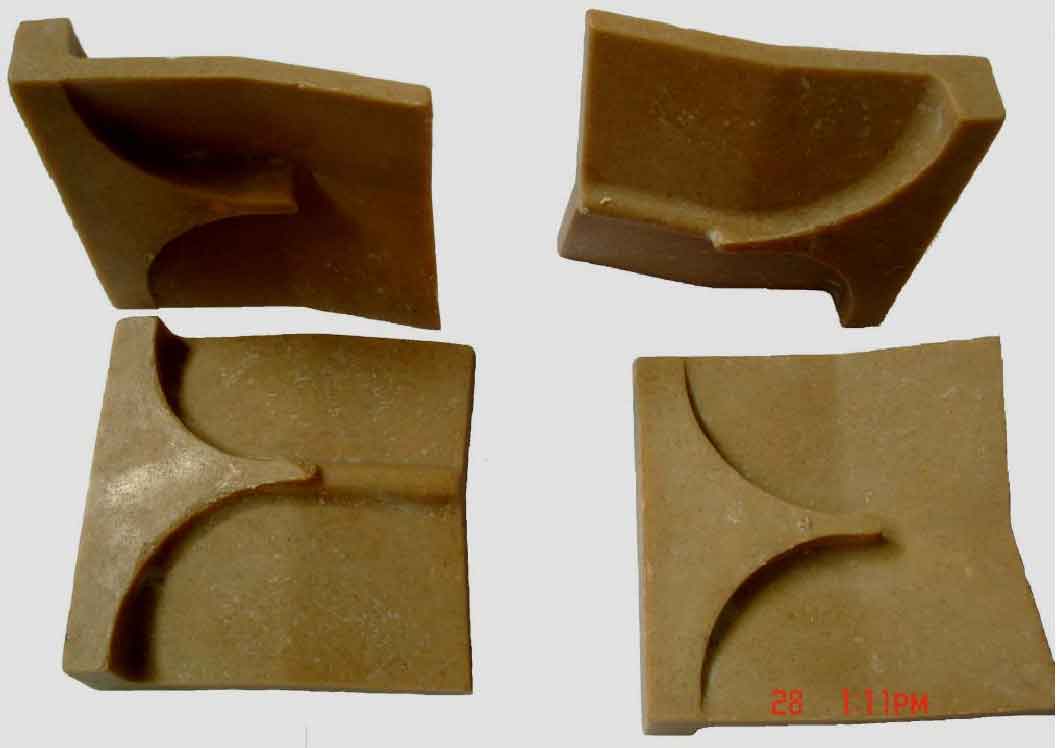

After the above process preparation, the investment mold of the pressed single impeller blade is shown in the figure below.