The first step in the preparation of the melt mold shell is to manufacture the melt mold of the whole impeller blade. The cavity with smooth inner surface and accurate size of the shell is formed by the investment mold, so the investment mold itself must have high dimensional accuracy and fine surface roughness. The investment molding material itself also meets a series of requirements for subsequent shell manufacturing. The preparation process of investment casting impeller shell mainly includes the design and manufacture of pressure mold, the selection of mold materials, the formulation of appropriate pressure injection process, the design of reasonable investment casting impeller blade assembly welder assembly and assembly welding process.

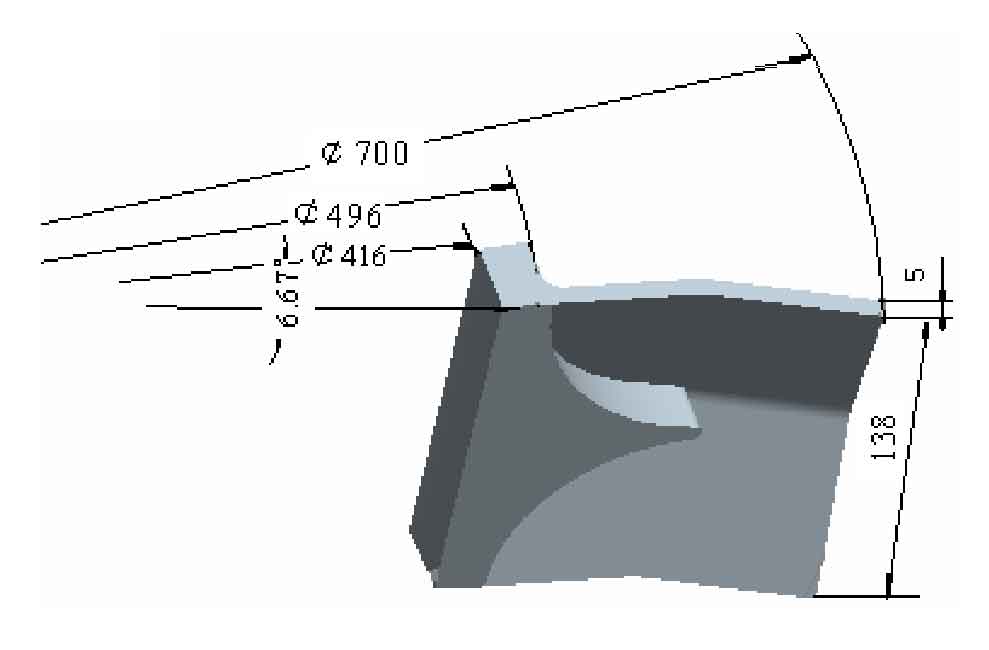

The geometry of the investment mold of the impeller blade is directly formed by the investment cavity, so the dimensional accuracy and surface roughness of the cavity have a great impact on the accuracy of the investment casting impeller blade. Considering that the machining allowances of the upper and lower parts are 5mm and 3mm respectively, the size of a single investment casting impeller blade is shown in the figure.

The surface roughness of the investment mold shall be finer than that of the investment casting impeller blade. The surface roughness of the investment mold is closely related to the surface roughness of the investment cavity and the process parameters of the pressure injection investment mold. The surface roughness of the investment mold becomes thinner with the surface roughness of the pressure mold cavity, but when the surface roughness of the pressure mold cavity becomes thinner to a certain extent, the subsequent surface roughness of the investment mold depends on the process conditions of the pressure injection investment mold. The surface roughness of each part of investment casting impeller blade is shown in the table.

| Molding part | Cavity | Movable block mating surface and positioning surface | Parting surface | Non working surface |

| Ra(µm) | 0.2-0.8 | 0.8-3.2 | 0.8-1.6 | 6.3-12.5 |