In the traditional sense of investment casting, the welding of investment module, that is, after removing flash, polishing and inspection, a single investment module is welded to the gate wax rod one by one with soldering iron to make the module. However, the assembly and welding of investment mold mentioned in the study is quite different from the traditional process. In order to ensure the accuracy of the investment mold size of the complex blade during the assembly and welding of the module or the coating process, reasonable tooling must be used to ensure the normal operation of the coating.

1.Conditions to be met by welder assembly

(1) The designed tooling shall ensure that the size and shape of the welding module of the whole investment casting impeller blade meet the actual technical requirements.

(2) Ensure that the investment mold of the assembly welding investment casting impeller blade has sufficient strength during the coating process.

(3) The designed tooling shall be simple and practical to ensure the normal operation of assembly welding and coating processes.

2.Design of welder assembly

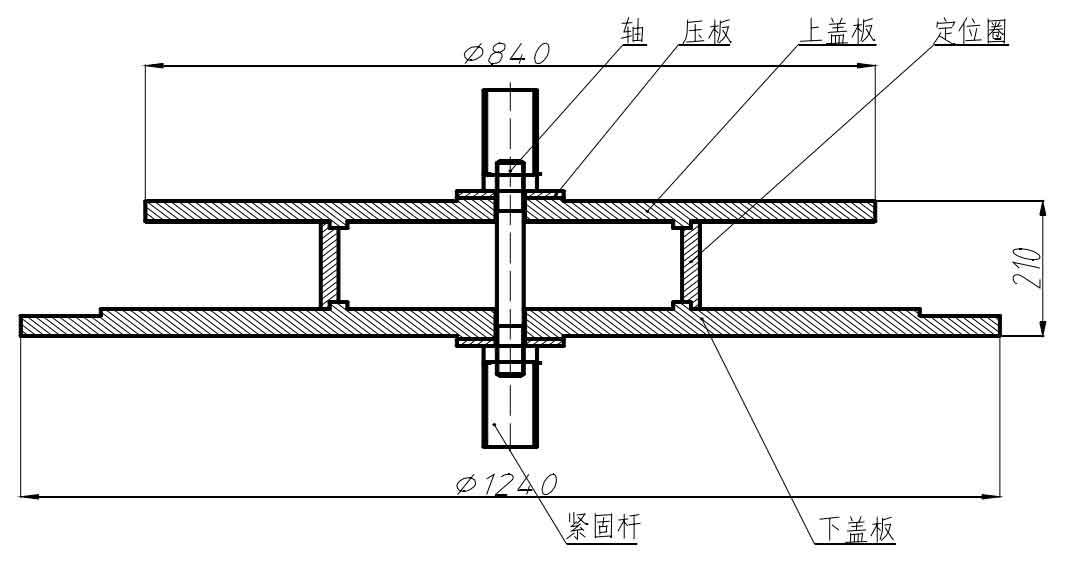

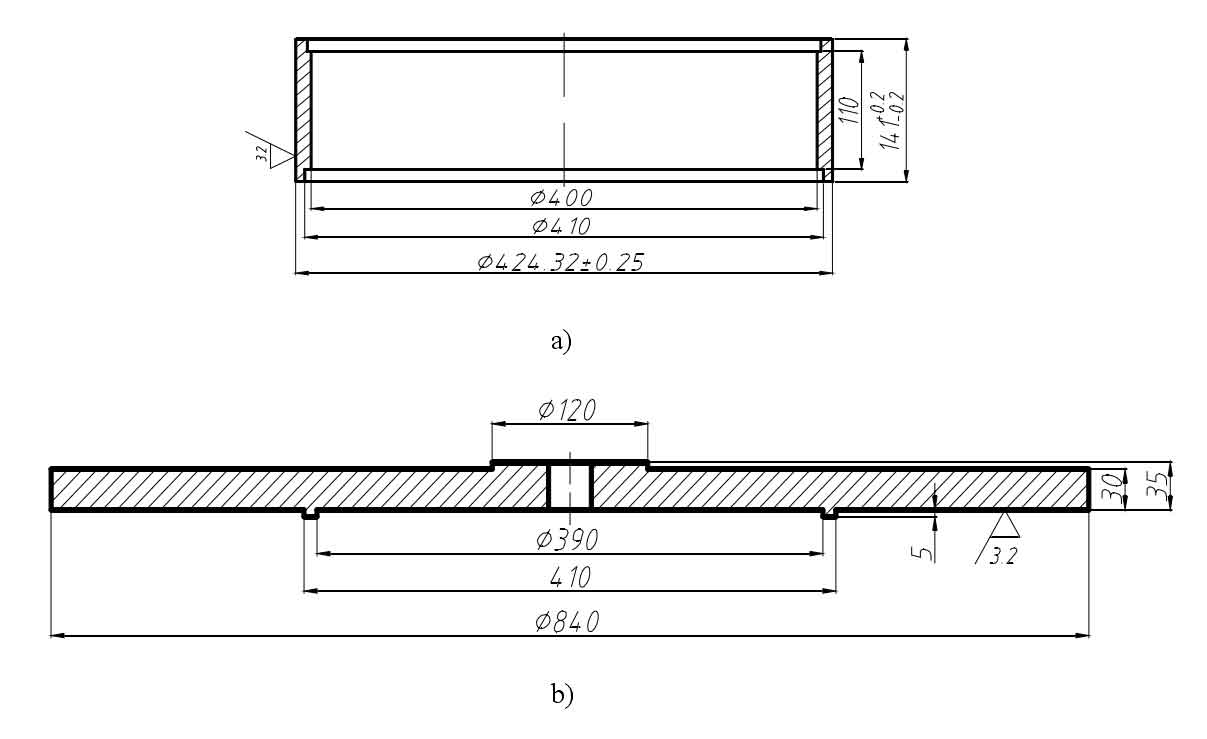

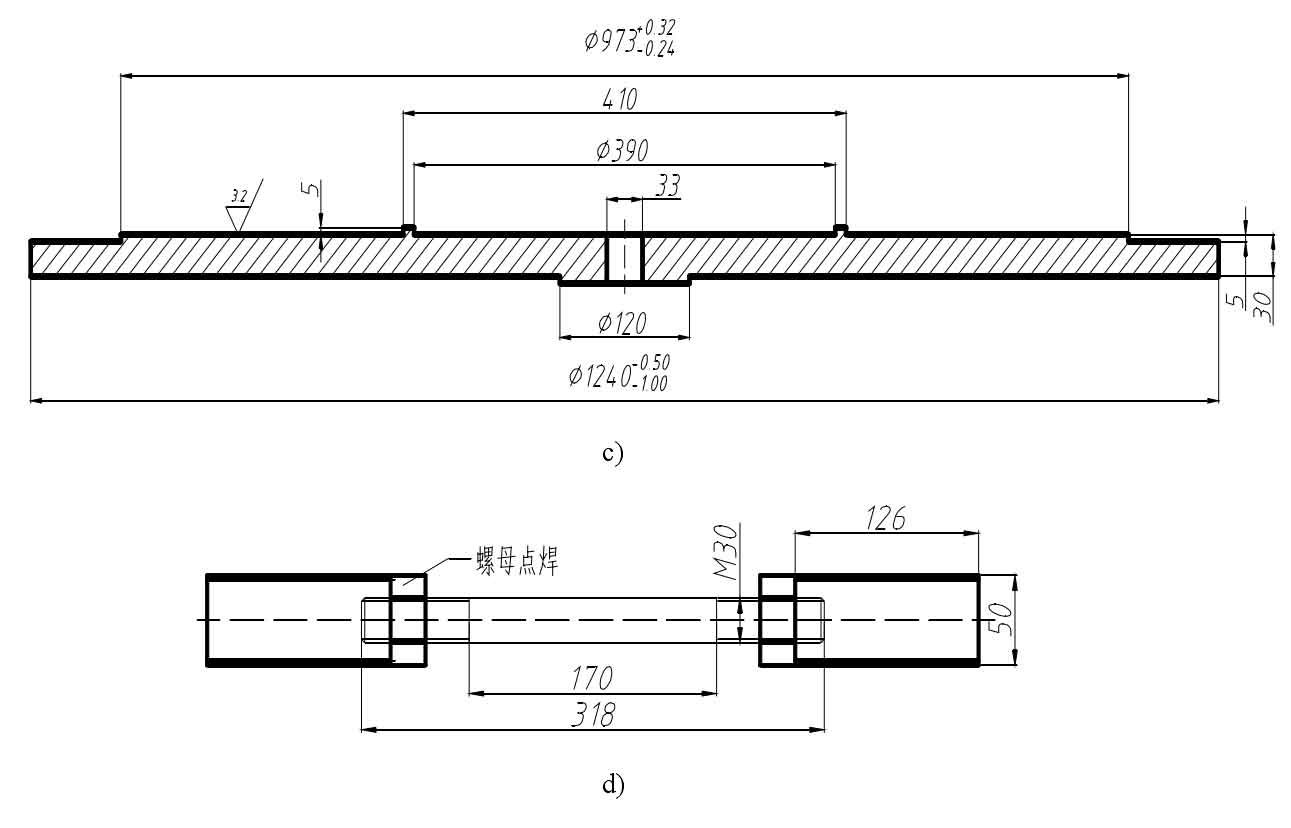

In order to ensure that the above points can be met, during the preparation process, we designed the blade assembly welder assembly drawing shown in Figure 1 and the main parts drawing of investment casting impeller tooling shown in Figure 2 to ensure the normal operation of investment casting impeller blade assembly welding and coating process.