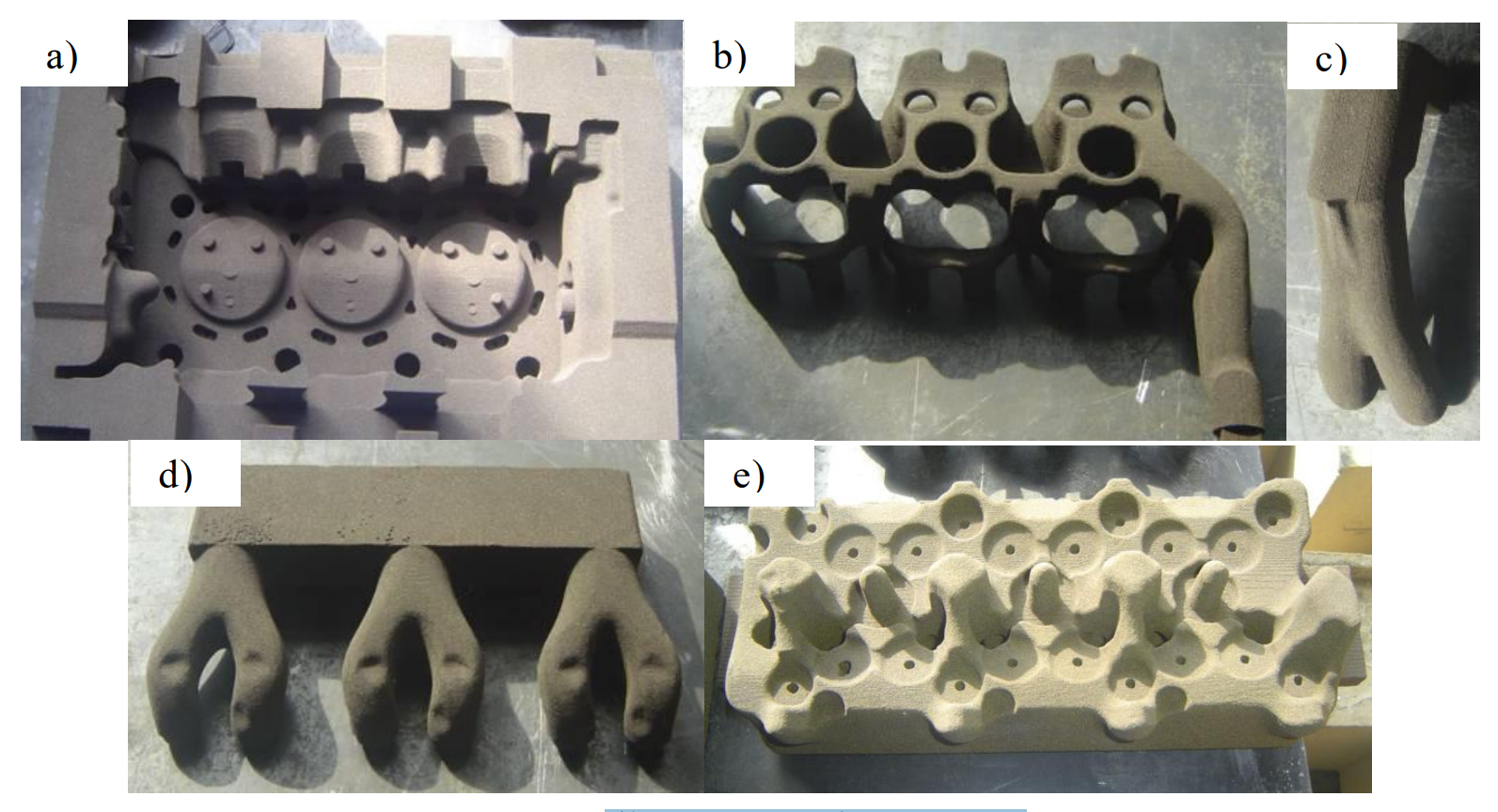

The manufacturing process of the scheme is used for the manufacturing and processing of casting sand mold, and the coated sand core manufactured by laser selective sintering process is shown in Figure 1. Figure a shows the base core, which forms the top surface of the combustion chamber of the engine cylinder head. Since the surface of the combustion chamber is not machined, its surface roughness requirements are relatively high, which needs to be polished manually in the later stage. Figure B shows the water jacket core, which forms the cooling water channel of the engine cylinder head. Its surface quality does not meet the requirements, and the surface of the sintered sand mold casting sand core meets the requirements. Figure C shows the intake channel core and figure D shows the exhaust channel core, which are the intake channel and exhaust channel of the engine cylinder head respectively. Generally, there are high requirements for dimensional accuracy and surface quality. Figure e shows the oil passage core, which forms the oil passage system of the engine cylinder head. Generally, the surface quality is not too high.

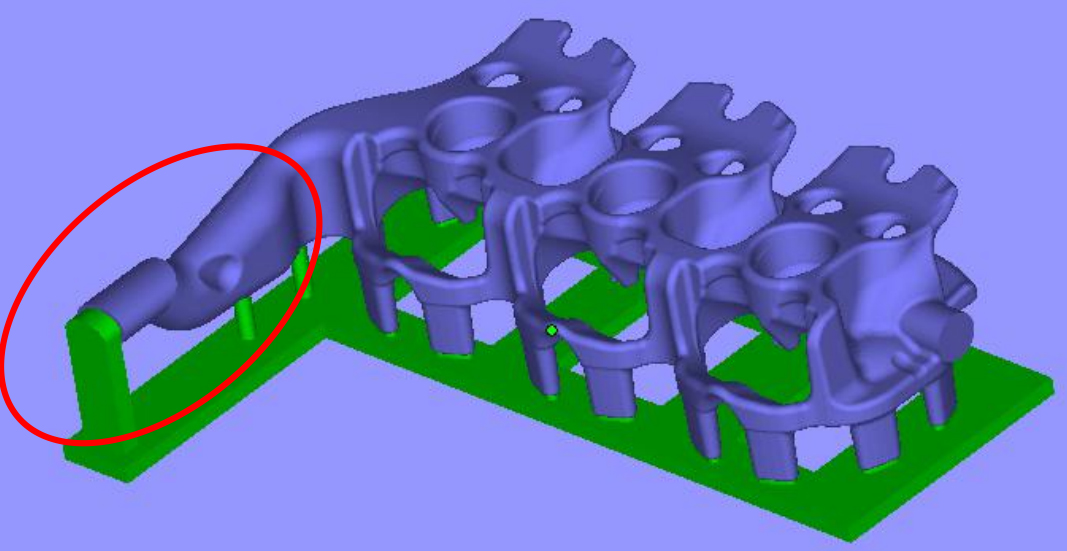

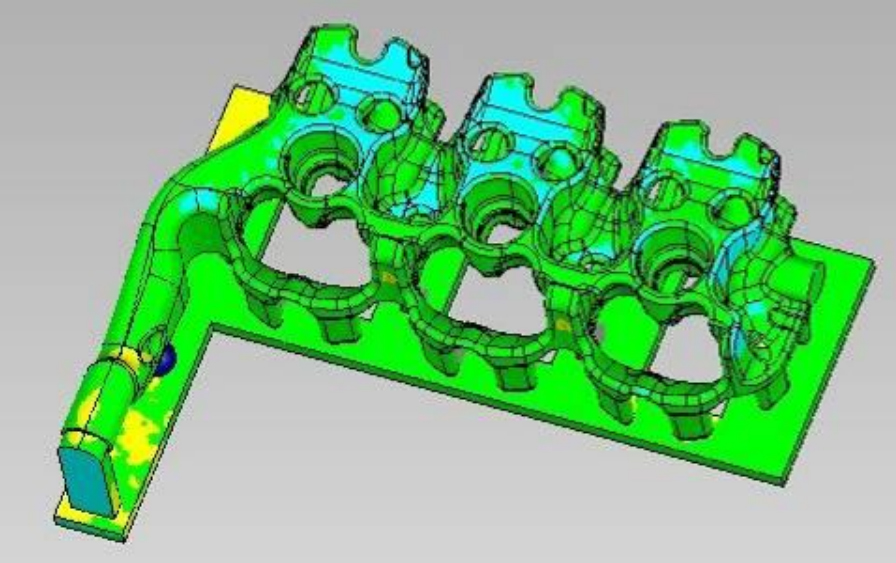

Due to the complex structure and thin wall thickness of the water jacket core, it is not only easy to be damaged during cleaning, but also very easy to deform the position of the water jacket core head in Figure 2 during secondary curing. Because the resin material needs to undergo the transformation from thermoplastic stage to thermosetting stage in the baking hardening process, even with the support of glass beads, the cantilever structure may still be deformed, and an additional support structure is required. By adding support and base on the three-dimensional data, figure 2 shows the water jacket core after adding support, and the green part is the additional support. After the secondary solidification of the casting sand mold, the support is cut and removed. Through the support design of water jacket, the sand core of sand mold casting is not easy to be damaged during cleaning, and the deformation of sand core in secondary solidification of sand mold casting is reduced. Fig. 3 shows the size detection results of the water jacket core using the three-dimensional scanning detection equipment. The green area in the figure is within ± 0.3mm of the size deviation.

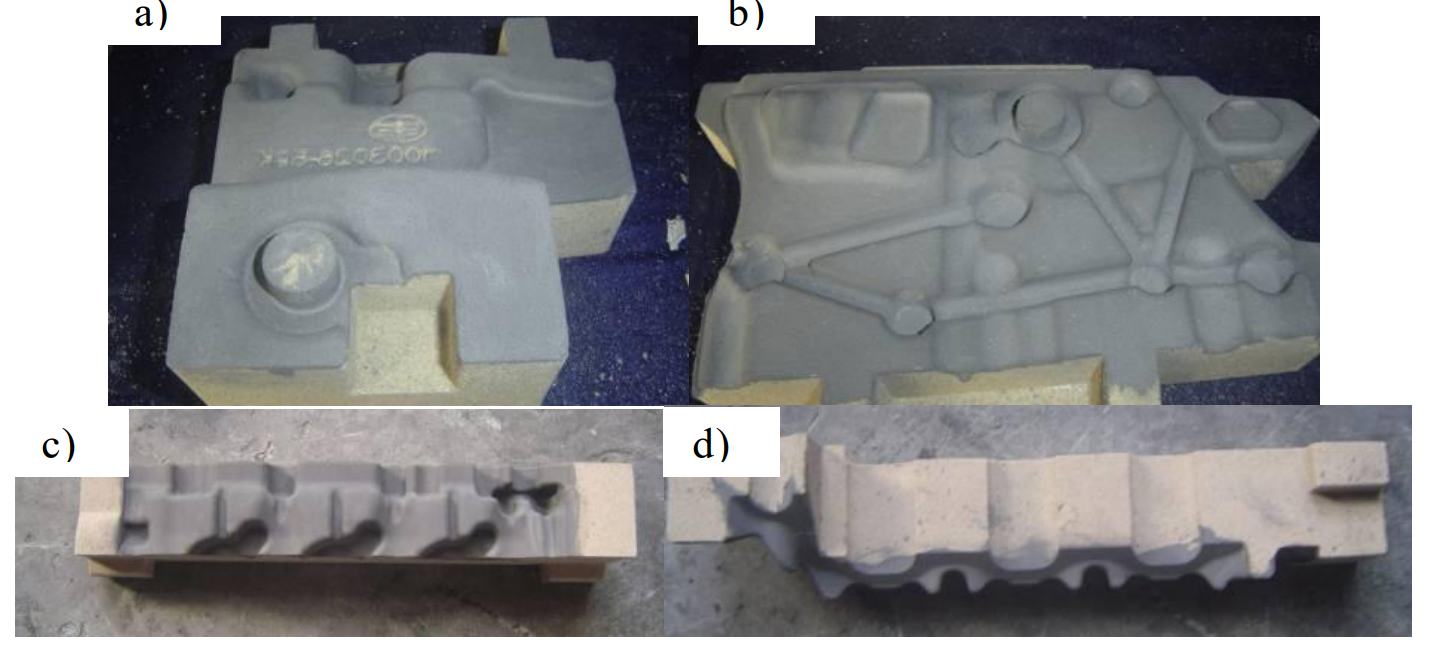

The sand mold of casting processed by digital Moldless mold is shown in Figure 4.