The national standard GB / T 9439-1988 gray iron castings divides the inspection of mechanical properties into tensile strength and hardness. The tensile strength is divided into the tensile strength of single cast test bar and the tensile strength of attached cast test bar. Practice has proved that the tensile strength of single cast test bar can not timely and correctly reflect the mechanical properties of each furnace of valve castings, while the attached cast test bar brings great trouble to the production and manufacturing and does not meet the requirements of mass production of valve castings. It is a practical and convenient method to test the mechanical properties of gray iron castings by hardness. When the national standard GB / T 12226-2005 technical conditions for gray iron castings of general valves was revised, the clause taking hardness as the acceptance standard was also added. The hardness test method shall be in accordance with Appendix A of GB / T 9439-1988.

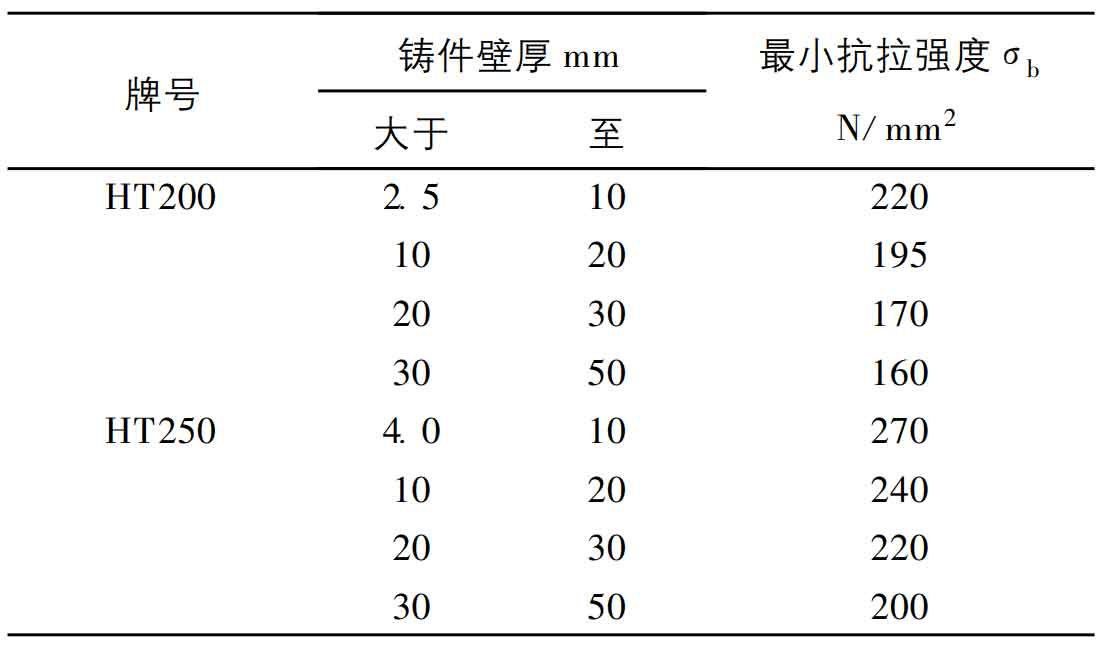

The grades of valve gray iron castings are mainly HT200 and HT250. Therefore, these two grades are used to analyze the relationship between the grade, hardness, tensile strength and wall thickness of castings. According to GB / T 9439-1988, the reference values of tensile strength that can be achieved by gray iron castings with different grades and wall thickness are shown in Table 1.

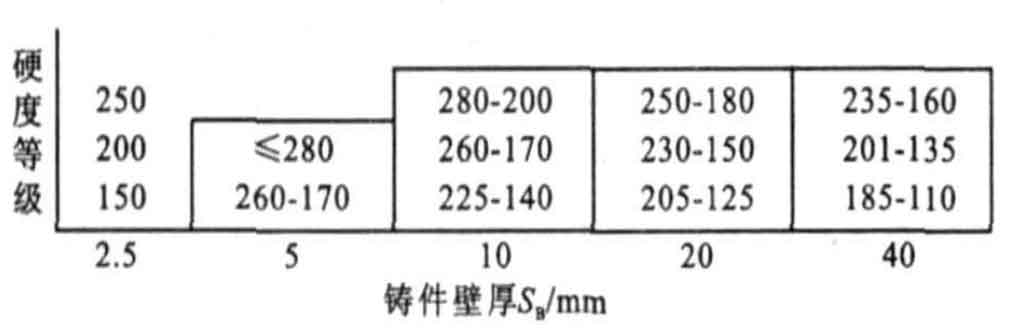

According to the provisions of Appendix B of GB / T 9439-1988 and ISO 185-1988-12-15 classification of gray iron casting, the reference values of the relationship between hardness and tensile strength are shown in Table 2.

According to Annex C of ISO 185-1988-12-15 classification of gray iron casting, the relationship between hardness and wall thickness of gray iron castings is shown in Table 3.

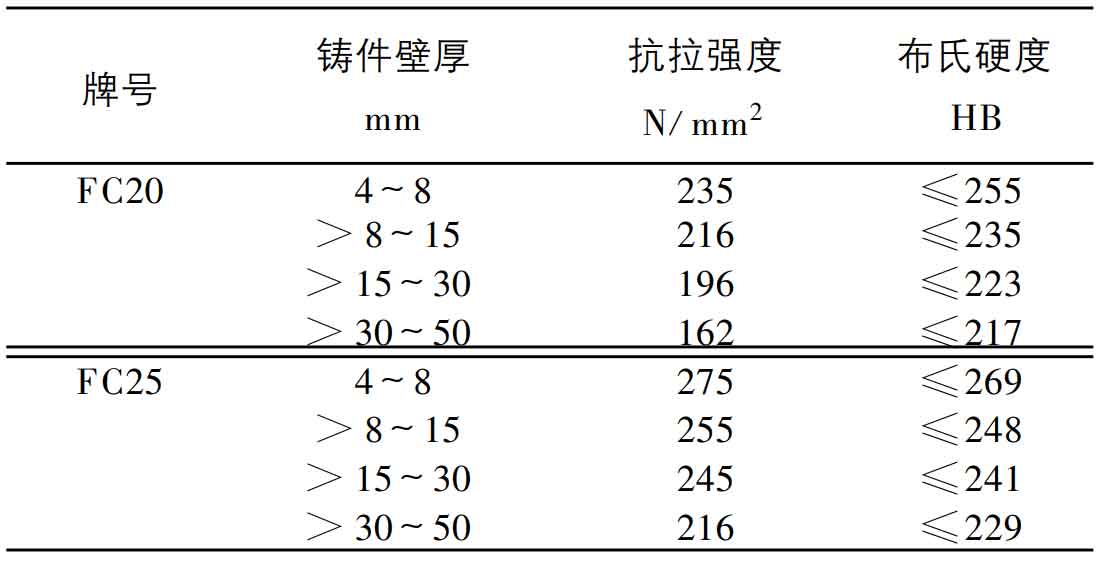

Japanese Standard JIS g5501 gray iron castings also provides a reference value for comparison of mechanical properties and hardness (Table 4).

Through analysis and comparison, it is proved that the brand of castings has a certain corresponding relationship with different casting wall thickness, tensile strength and Brinell hardness. At the same time, this corresponding relationship will be different from different foundries, while the corresponding relationship is the same for castings with the same foundry, the same brand and similar wall thickness.