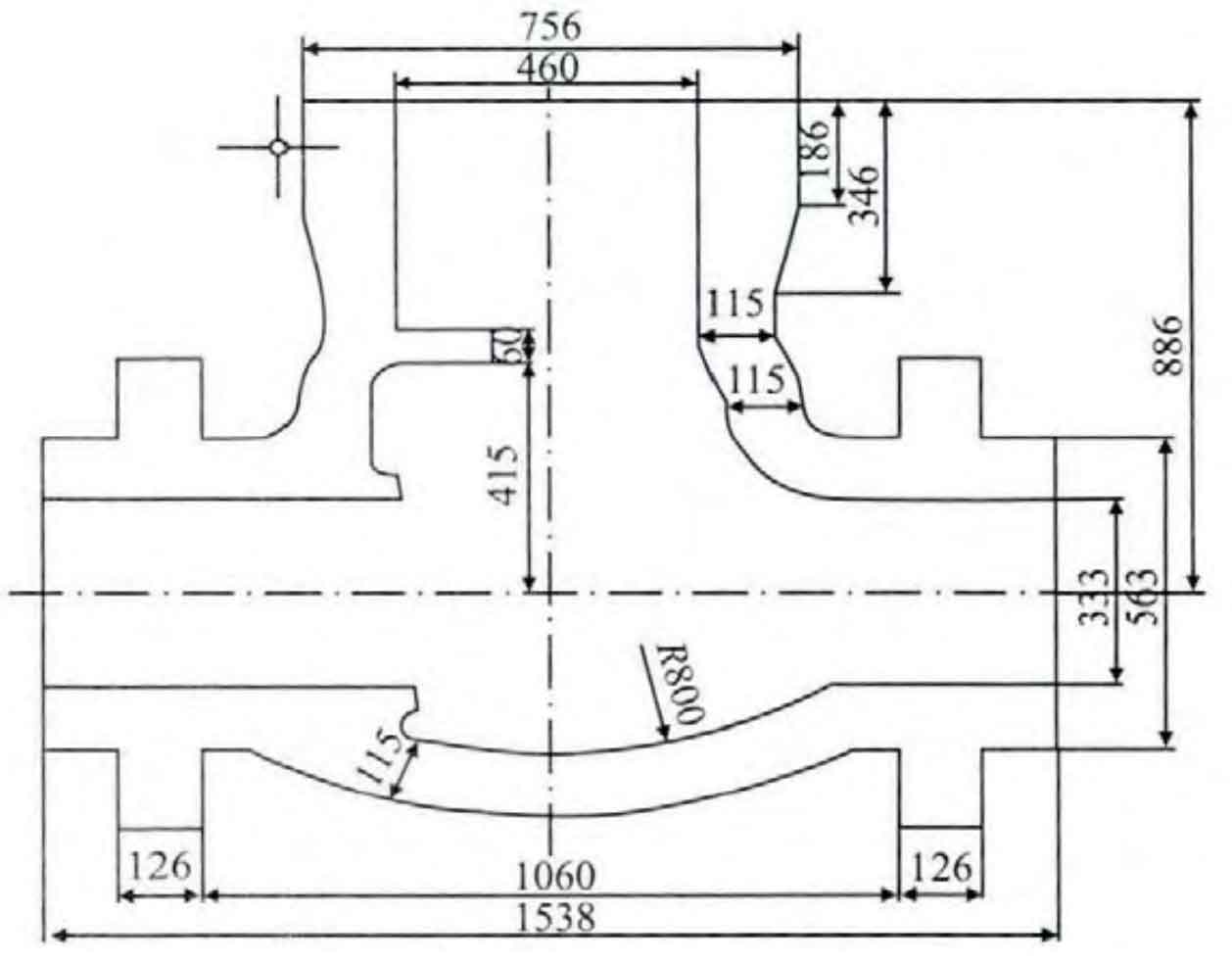

The structure of dn400-2500lb valve casting is shown in the figure. The blank weight of the valve casting is 4300 kg, and the overall dimension is 1538 mm × 1 310 mm × 840mm。 The shape of the valve casting is three-way tubular. Each pipe is a circular pipe. The center line of each pipe is on the same plane. There are flanges at the two pipe orifices in the same axis. The wall thickness of the pipe orifice in the vertical direction increases. All the pipe orifices are processed. The wall thickness of the main body of the pipe is 115 mm. The pipe wall is thick and basically uniform, and a hot joint is formed at the intersection of the pipe.

The main body of the valve casting is a circular pipe, which has the common characteristics of circular castings. The concentricity between the pipes is difficult to ensure, and the wall thickness tolerance of the valve casting is difficult to control. It is difficult for the annular pipe to feed the pipes in three directions at the same time. Therefore, these factors should be fully considered when designing the casting process of high temperature and high pressure valve.