The alloy element Cr content of cf8c material is high. The high melting point of Cr increases the liquidus temperature of liquid steel and reduces the fluidity of liquid steel. It is easy to produce cold shut and surface wrinkle during the pouring process of valve castings. Cr is easy to oxidize in molten steel to form chromium oxide film, and oxidation inclusions are easy to occur in case of disordered filling. The above factors shall be fully considered when setting the gating system of valve castings to ensure rapid and stable mold filling.

(a) Pouring time. According to the liquid weight of valve castings, the approximate pouring time of valve castings can be found out according to table 1, and the pouring time of valve castings can be determined in combination with the actual production. The casting liquid weight of the valve is 9350 kg. According to table 1, the pouring time is 40 ~ 150 s. In order to ensure fast and stable mold filling, combined with the actual production, the pouring time is t = 105 s.

| Mass / kg | Pouring time / S |

| 500~1 000 | 12~20 |

| 1 000~3 000 | 20~50 |

| 3 000~5 000 | 50~80 |

| 5 000~10 000 | 40~150 |

| ≥10 000 | 80~150 |

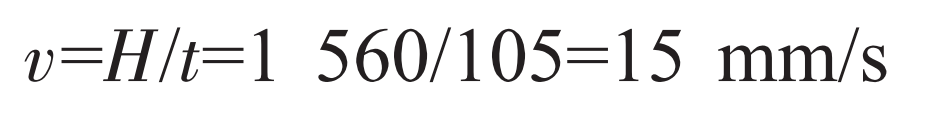

Whether the setting of valve casting pouring time is appropriate can be checked by the rising speed V of molten steel in the mold cavity during valve casting pouring. The rising speed V of liquid level is calculated according to the formula:

Where: H is the height of valve casting, mm; T is the pouring time, S.

According to the production experience of ZHY casting, the rising speed of liquid steel in the mold cavity is more appropriate between 10 ~ 20 mm / s when pouring stainless steel.

(b) Mass flow rate of molten steel. The mass flow rate V is calculated according to the formula:

Where: G is the mass of valve casting, kg; N is the number of ladle pouring at the same time; N is the number of plug blocks used for each ladle; T is the pouring time of molten steel.

Calculated v = 9 350 / 105 = 89 kg / s.

(c) Wrapped hole diameter. According to the calculated liquid steel mass flow rate, the ladle hole diameter can be found out according to table 2. According to the mass flow rate of liquid steel, the diameter of ladle hole is Φ 60 mm。

| Wrapped hole diameter Φ/ mm | Liquid steel mass flow rate / (kg · s-1) |

| 30 | 10 |

| 35 | 20 |

| 40 | 27 |

| 45 | 42 |

| 50 | 55 |

| 55 | 72 |

| 60 | 90 |

| 70 | 120 |

| 80 | 150 |

| 100 | 190 |

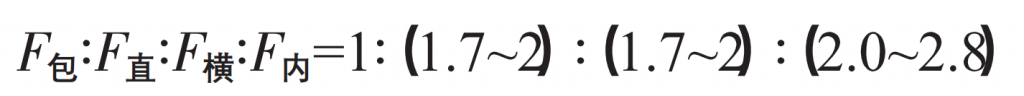

d) Calculation of sectional area of each component of gating system of valve casting. When pouring steel castings with plug rod ladle, open pouring system is adopted, and the proportion of cross-sectional area of each element is:

According to the ladle hole diameter, the design size of each part of the gating system of the valve casting is calculated as follows: ladle f= Φ 60 mm, f straight= Φ 80 mm, f transverse= Φ Within 80mm and F= Φ 50 mm (4 off).