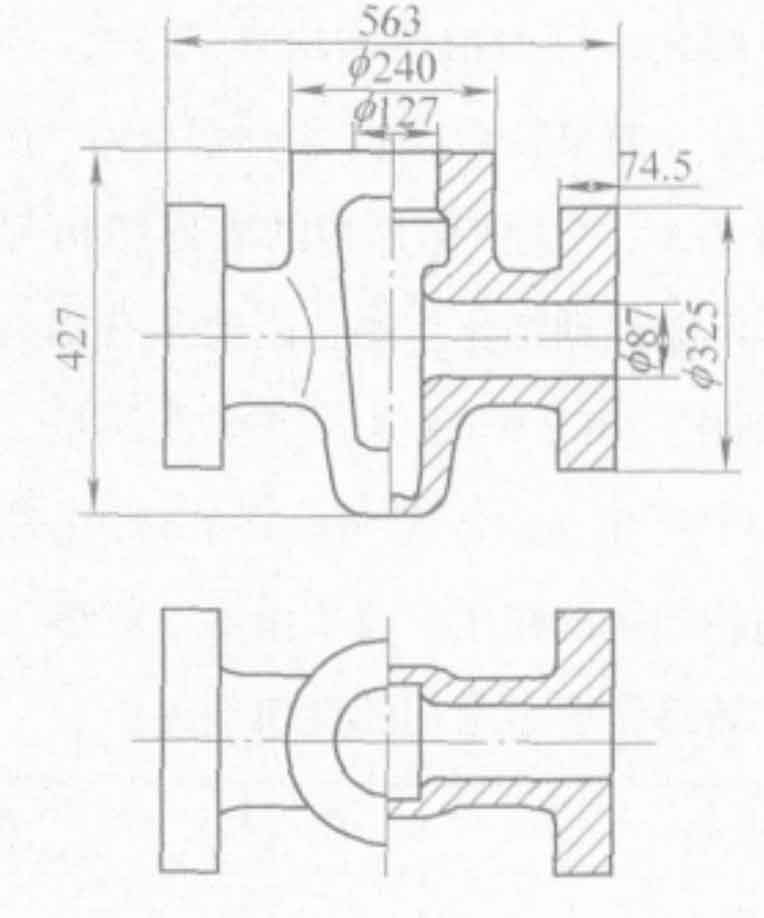

High pressure valve is one of the main parts of oil and gas production wellhead device, and its body structure is shown in Figure 1. Technical requirements: the casting shall be free of crack, shrinkage cavity, inclusion and other casting defects. After 70MPa hydraulic test, leakage is not allowed; Fluorescent powder flaw detection is required for non machined surfaces, and cracks are not allowed; Wet magnetic particle flaw detection shall be carried out on the machined surface, and inclusions, pores, cracks and casting defects are not allowed. The material is zg1cr13.

1.Process comparison and use of heating riser

ZHY casting has been engaged in the production of high-pressure valve casting body for many years, and has successively adopted the following three process schemes for production test.

(1) Water glass quartz sand is used. Since the quartz sand has not been well coated so far, sand inclusion often occurs when processing the inner cavity of the valve body, the surface quality is also very poor, and micro cracks often appear in flaw detection.

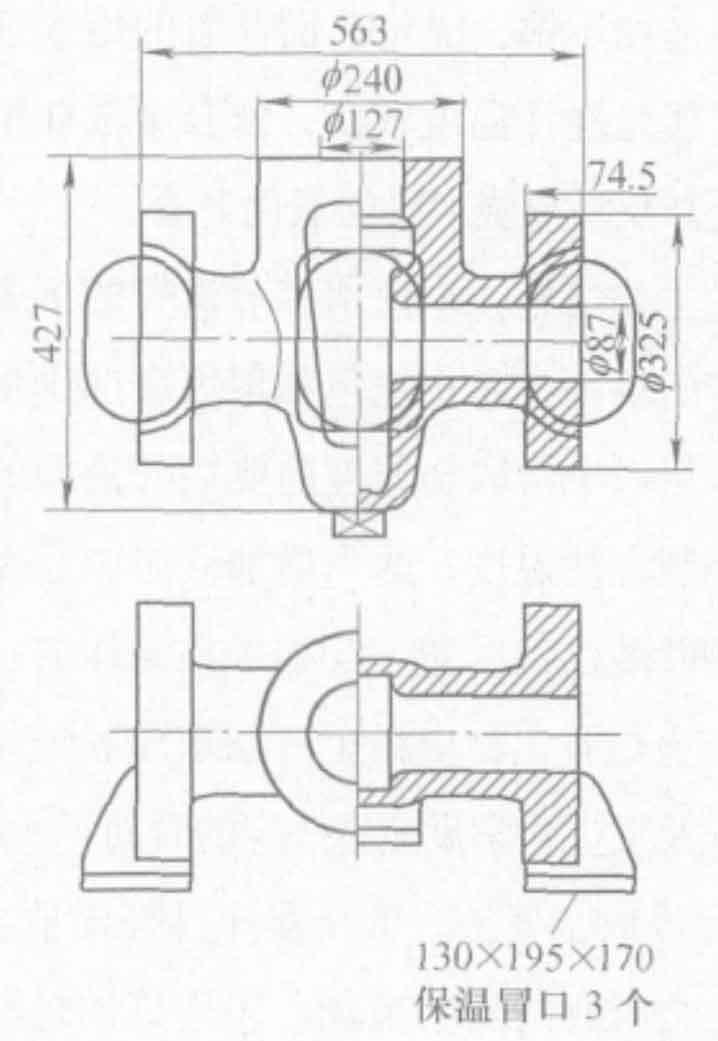

(2) The water glass quartz sand core is adopted, and the hot joint at the valve seat of the valve casting is isolated, so the method of placing the riser on the top needs to be adopted (as shown in Figure 2). However, due to the large size of the riser, it is difficult to remove, and the process yield of the valve casting is only 50%, so the sand core cleaning is difficult and uneconomical.

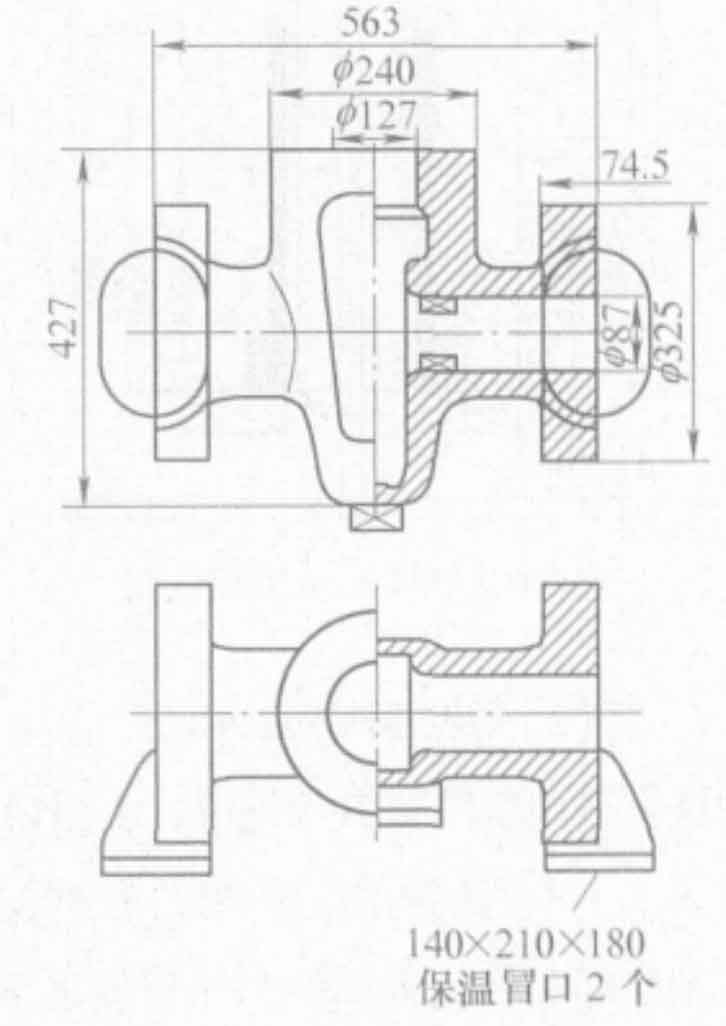

(3) The furan resin sand is used as the sand for the mold core, and the thermal insulation riser is used on the side flange and the upper part of the valve seat (as shown in Figure 3). Due to the slow heat conduction of furan resin sand, the thermal insulation effect of the thermal insulation riser is not obvious, so the size of the riser is relatively large, and the core sand at the valve seat has a large gas generation due to the thermal effect of the top riser, which often causes gas shrinkage cavity and casting defects at this part and is scrapped.

2.Application of heating riser

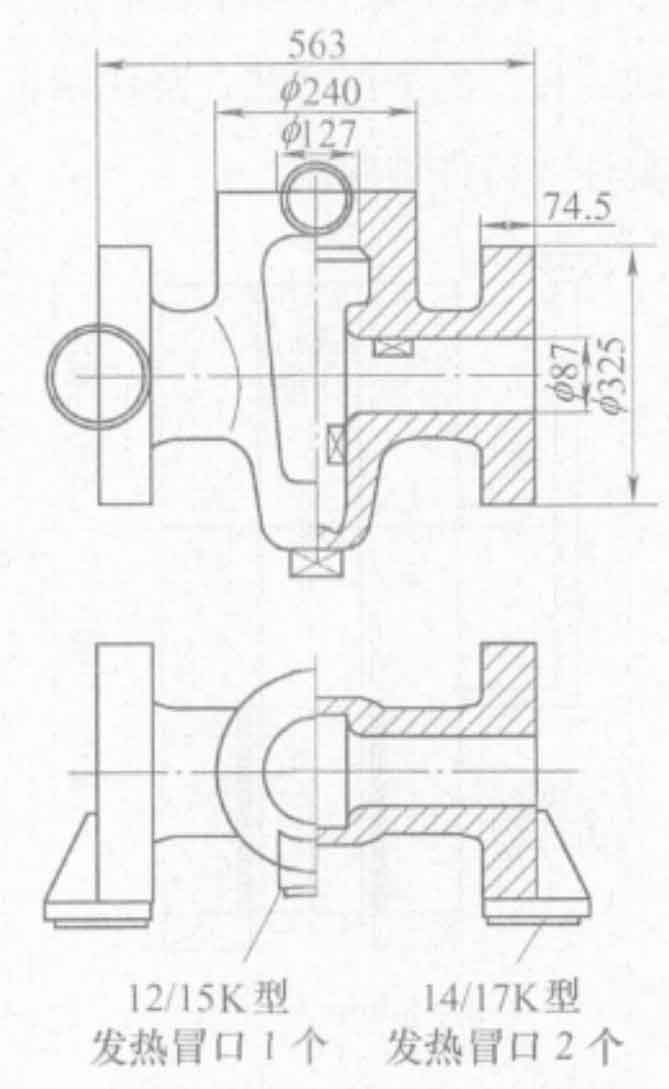

In view of the above situation, we used the heating riser for zg1cr13 high-pressure valve body casting. The mold core was made of furan resin sand, and the heating concealed riser was placed on the top of the middle flange and side flange. The valve seat was cooled by cold iron, and the tail was also cooled by external cold iron (as shown in Figure 4). Zg1cr13 high-pressure valve casting was successfully produced. Through the dissection and coloring inspection of the valve casting body, the structure of the valve casting is dense. Nearly 2000 pieces have been produced, with the process yield of valve castings reaching 78% – 80% and the genuine product rate reaching more than 96%.

The casting produced by furan resin sand has smooth surface and accurate size, but due to its slow heat conduction, if the ordinary fiber insulation riser is used, the insulation effect is not obvious. For high alloy pressure steel castings with dense structure, such as zg1cr13, the use of heating riser has obvious thermal insulation performance, which can significantly reduce the size of riser, improve the process yield of valve castings, and reduce the workload of subsequent processes such as gas cutting and air gouging. At the same time, the size of riser is small, which reduces the thermal impact on sand core and greatly reduces the probability of gas shrinkage cavity, The genuine rate of valve castings is significantly improved and the economic effect is obvious.