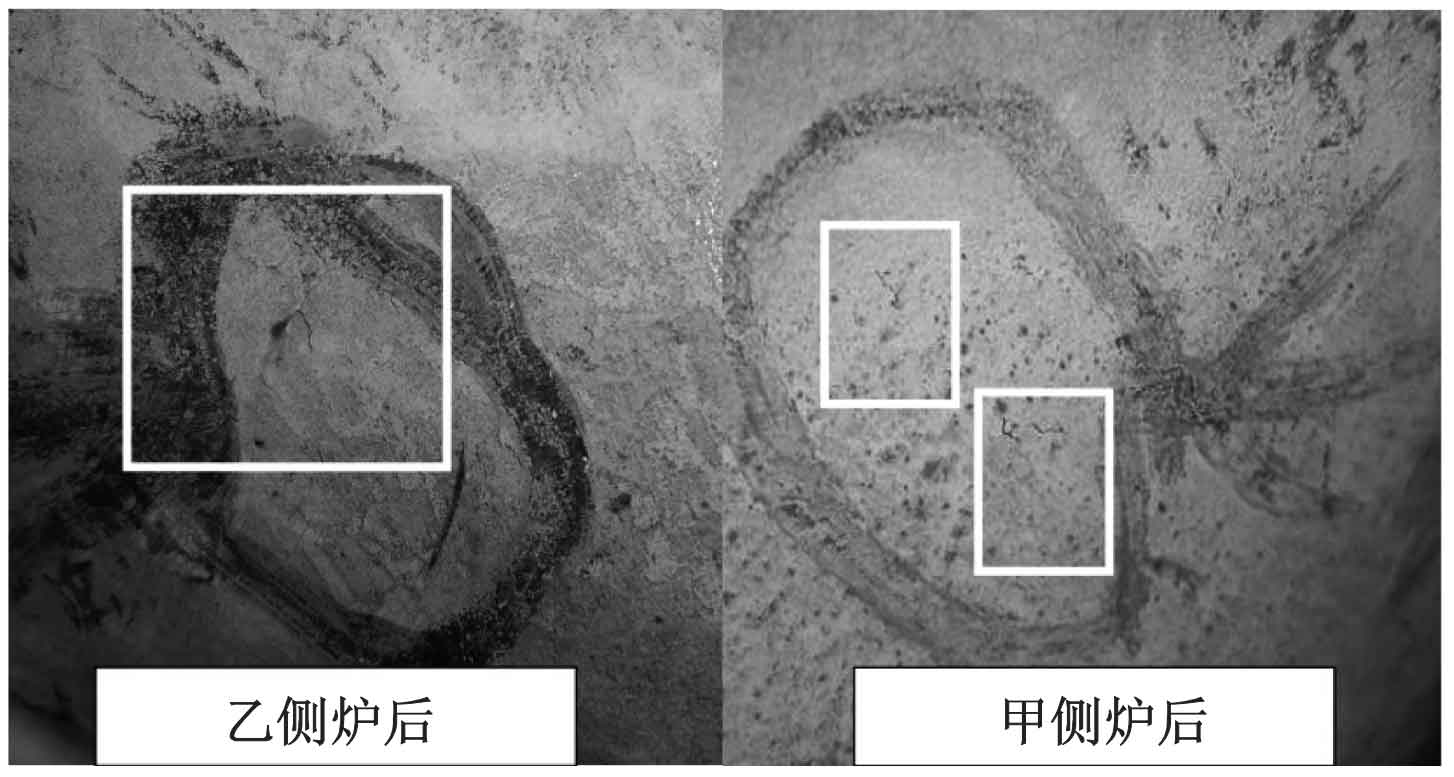

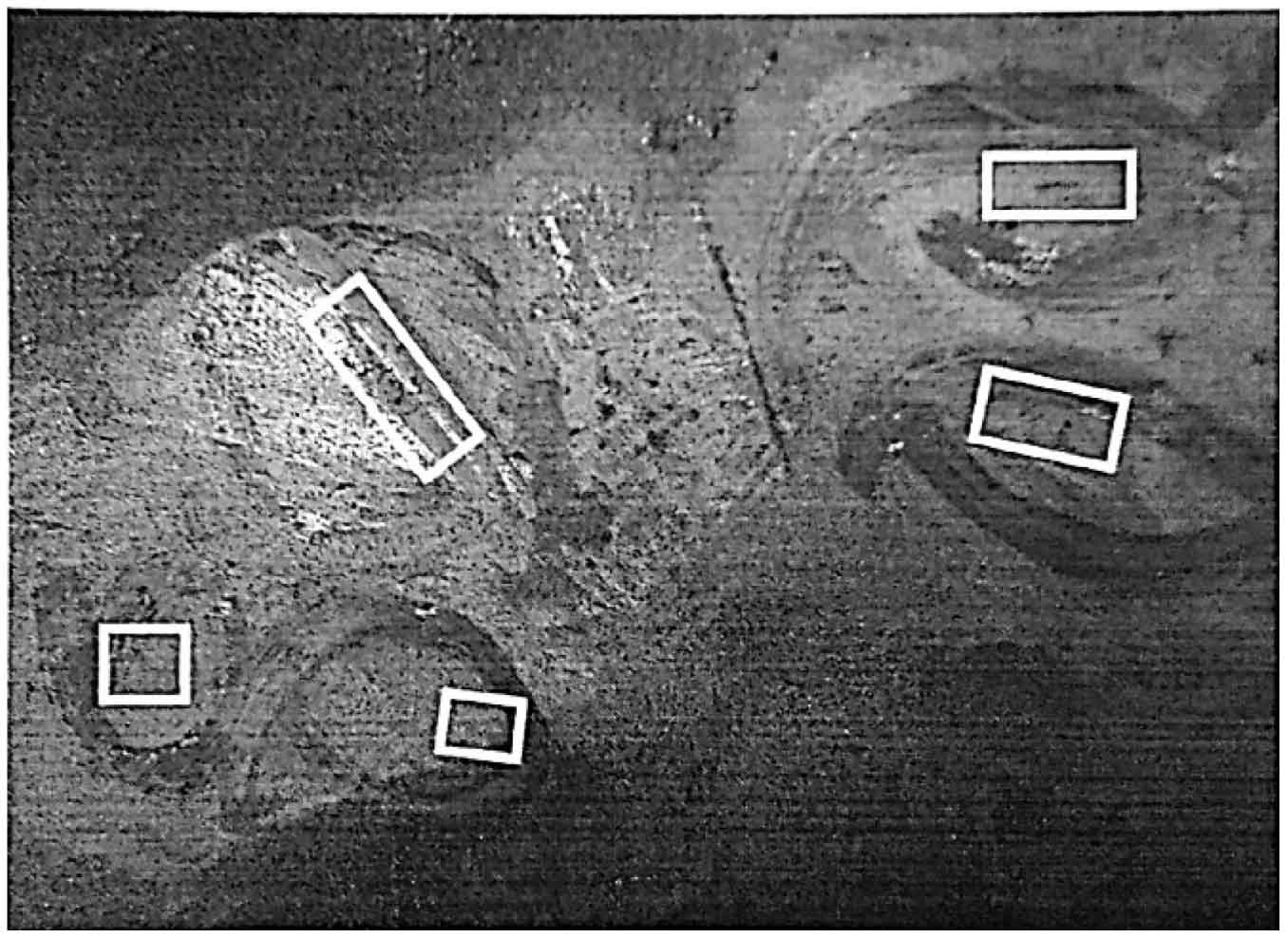

Through magnetic particle testing, it was found that there were multiple cracks on the shoulder behind the furnace on the second side of the main steam gate valve body casting of boiler 1, with the longest crack of 5 mm. There are several cracks on the rear shoulder of side a furnace, with the longest crack of 6 mm, as shown in Figure 1. It is found that there are several cracks on the front shoulder of the boiler on the second side of the main steam gate valve body casting of boiler 2, with the longest crack of 3 mm, as shown in Fig. 2.

Through metallographic examination, it is found that the structure of the front shoulder of the furnace on the side a of the main steam gate valve body casting of No. 1 boiler is ferrite plus a small amount of pearlite and carbide, as shown in Fig. 3. The structure of the front shoulder of the main steam gate valve body casting on the side a of boiler 2 is ferrite plus a small amount of pearlite and carbide, as shown in Fig. 4.

The valve body casting of main steam gate valve of 1 boiler has been tested for hardness, and the hardness value is 114 ~ 125 HBW (as shown in table). The valve body casting of main steam gate valve of 2 boiler has been tested for hardness, and the hardness value is 114 ~ 123 HBW.

| Serial number | Furnace 1 | Furnace 2 |

| 1 | 114 | 114 |

| 2 | 118 | 117 |

| 3 | 114 | 119 |

| 4 | 125 | 121 |

| 5 | 118 | 123 |

.jpg)

.jpg)