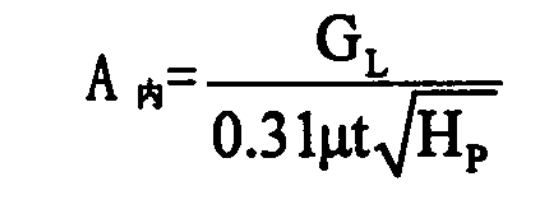

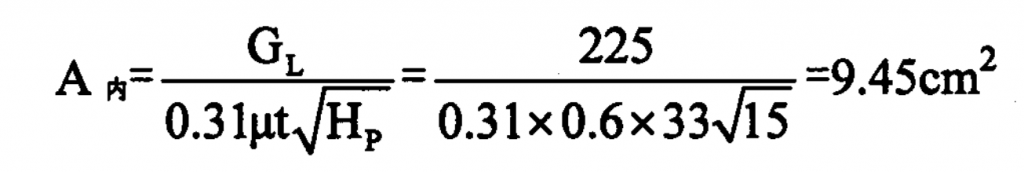

Among the sub units of the pouring system of tractor box castings, the unit with the minimum cross-sectional area is the blocking section of the pouring system. In the design, the pouring system of tractor box castings adopts closed type, that is, a cup > a straight > a cross > a inside, so the minimum cross-sectional area is equal to the minimum total cross-sectional area of the ingate. The blocking section method is adopted for design, and the minimum cross-sectional area of the ingate is:

Where:

μ= 0.55 ~ 065, take 0.6;

Total weight of molten metal in GL-1 cavity, kg:

HP – average pressure head, cm.

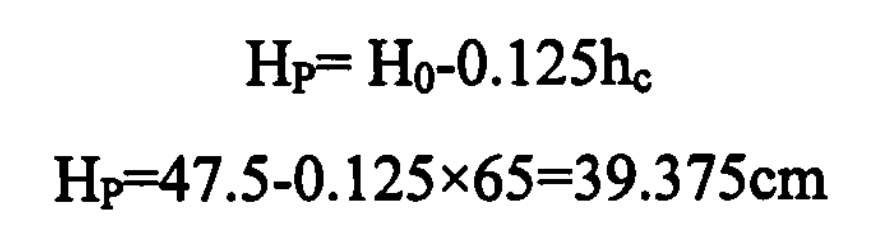

According to the designed gating system schemes of three tractor box castings, the height of the rectangular boss of the middle casting is 650mm, and the designed height of the sprue and gate higher than the upper half of the casting is 150ram, that is, the total height of the sprue and gate ho is 475mm. It can be seen that the average static head height is:

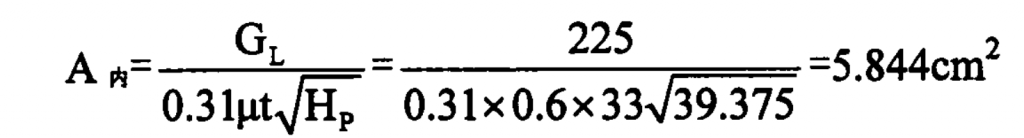

The total cross-sectional area is the minimum sprue:

The stepped gating system of tractor box casting adopts the same parameters as the mid injection gating system, and the total sectional area of the inner sprue is 5.844cm2.

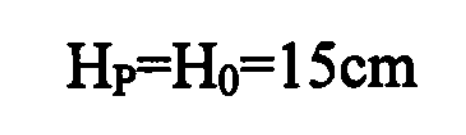

In the top casting gating system of tractor box castings, the height of the sprue and pouring port designed to be higher than the upper half of the casting is 150mm. Since the inner sprue is located at the top of the casting, that is, the height ho of the sprue and pouring el is 150mm, it can be seen that the average static head height is:

The total cross-sectional area is the minimum sprue: