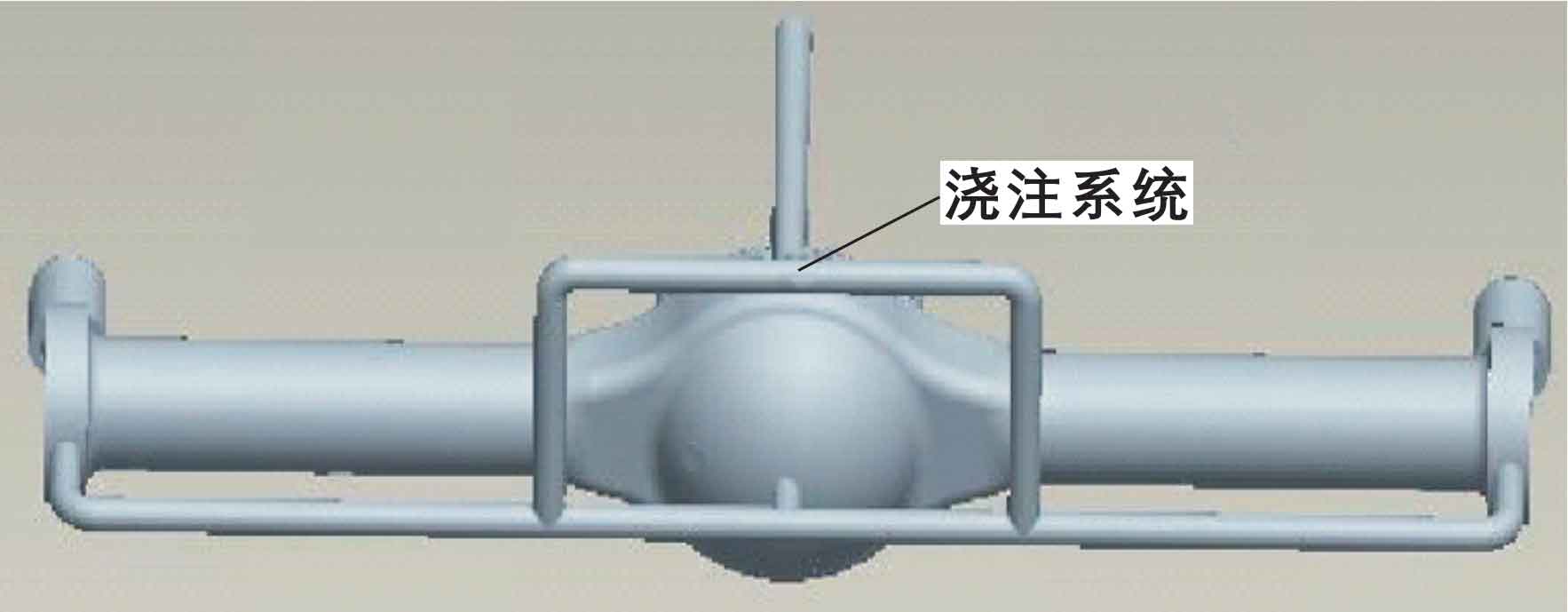

1. Optimization of gating system

In view of the turbulent flow caused by the unstable flow of liquid metal in the pouring process of the original process, the pouring system was optimized and improved. Firstly, the original closed gating system is changed to open gating system. According to the calculation of the minimum rising speed of liquid steel and pouring process, it is determined that the pouring time is changed to 24 s. According to the difficulty of the original system to ensure the quality of the middle position, the bottom pouring system is adopted. The sprue is conical, which can slow down the inflow speed of liquid metal and produce a certain pressure on the mold, and can effectively prevent the inflow of external gas. Two transverse sprues are used for vertical connection, and internal sprues are set in the middle and both ends of the casting, so that the important positions and thick positions of the casting can be fed, and the mold filling process of the casting can be accelerated at the same time. The optimized gating system is shown in Figure 1.

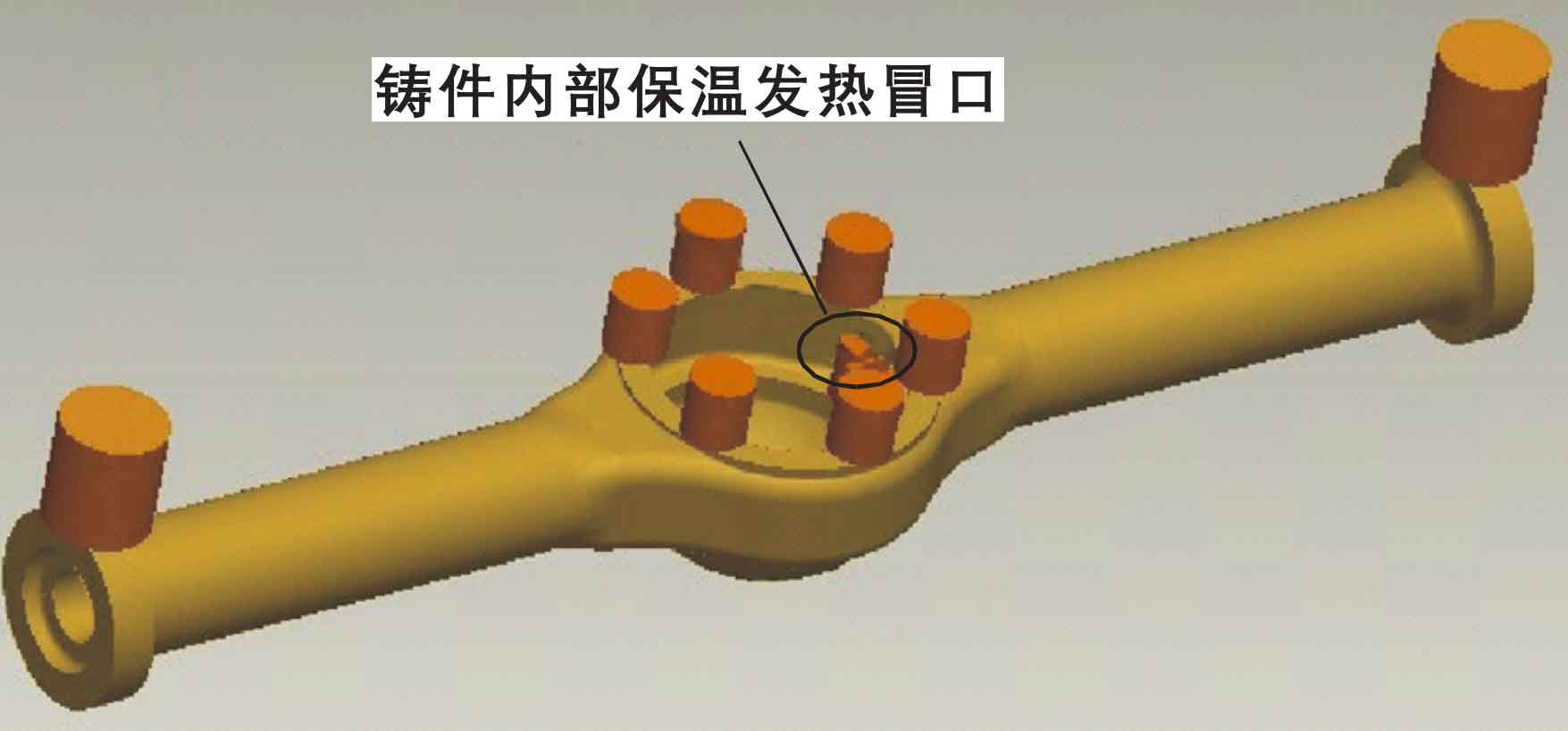

2. Riser improvement design

Change the original ordinary riser to thermal insulation riser. The change position of the wall thickness of the casting is mainly at the connection position between the middle shell and the tubes on both sides and at both ends of the casting. The hot joint is located at both ends and the middle arc part. Because the wall thickness of the middle circular arc part is small and the straight pipes on both sides are long, a group of thermal insulation risers are set inside and outside the middle shell for full feeding. The schematic diagram of riser is shown in Figure 2.

3. Coating process improvement

Coating is an important process that can not be ignored. After molding, alcohol based coating must be applied on the mold, which can increase the thermal resistance between the casting and the mold, reduce the heat transfer rate, further prevent cracks, and prevent the overheating and collapse of molding sand from affecting the quality of the casting. In addition, pay attention to the uniformity and thickness of the coating.