The tendency of shrinkage cavity and porosity casting defects is related to the solidification mode. During layer by layer solidification (smooth interface solidification and shell solidification), it tends to form concentrated shrinkage casting defects. The small crystallization temperature range of the alloy, the high cooling rate of the casting or the large temperature gradient on the section are conducive to the layered solidification mode: when it is solidified in paste or sponge, it tends to form shrinkage casting defects. The wide crystallization temperature range of the alloy, slow cooling of the casting or small temperature gradient on the section are conducive to this solidification mode. For a casting, there may be a combination of different solidification methods. For example, the surface of the casting is solidified in layers, and the central part may be solidified in paste or sponge. Therefore, shrinkage cavity and shrinkage porosity casting defects can occur in castings, and the volume of shrinkage cavity and shrinkage porosity casting defects can be transformed into each other due to different cooling conditions and solidification methods.

Nodular cast iron has the tendency of paste solidification. The volume of shrinkage cavity and shrinkage porosity casting defects changes with different mold conditions. For ductile iron castings cast with different rigid molds, the larger the size of the casting sample relative to the pattern, the larger the volume of shrinkage cavity (shrinkage porosity) casting defects; On the contrary, the smaller the size of the casting sample relative to the pattern, the smaller the volume of shrinkage cavity (shrinkage porosity) casting defects. It shows that the shrinkage cavity volume and the shrinkage volume of the casting shape are transformed into each other. This is due to the different degrees of softness of the shell, the different movement of the mold wall caused by the internal eutectic expansion pressure and the static pressure generated by the pressure head of the gating system.

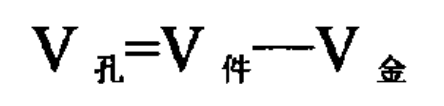

It is assumed that the filling is completed instantly, that is, the influence of filling time is not considered. According to the formation mechanism of shrinkage cavity and porosity casting defects, the theoretical value of its volume, y-hole, can be expressed by the difference between the overall volume of the casting and the volume of dense metal, y-gold, that is:

Where:

V hole – volume of shrinkage L in casting

Part V – the overall volume of the casting at the end of solidification and when the surface temperature is the junction

V gold – the volume of metal in the casting at the end of solidification

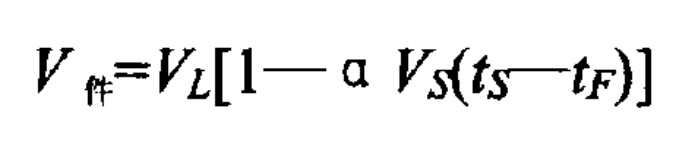

During the period from the completion of mold filling to the end of solidification, the outer surface of the casting decreases from the solidification temperature center to open, and the shell temperature decreases to produce solid-state shrinkage. When the solidification of the casting is terminated, the overall volume of the casting is:

Where VL – volume of casting after mold filling (when the casting surface temperature is the center), which is approximately equal to the volume of mold cavity:

α Vs is the solid shrinkage coefficient of metal.

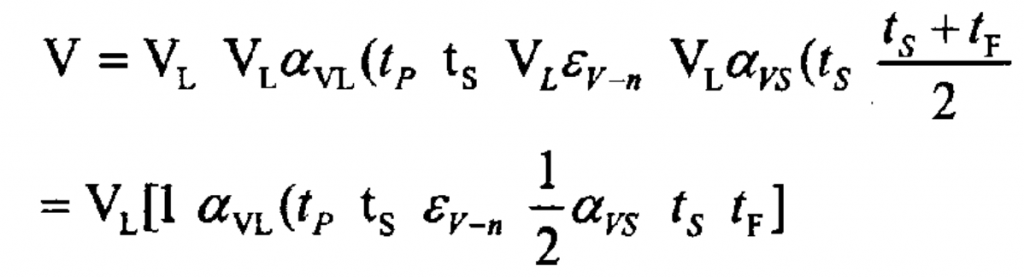

At the end of solidification, V gold is equal to the cavity volume minus the liquid shrinkage volume, solidification shrinkage volume and solid shrinkage volume of the casting metal, that is:

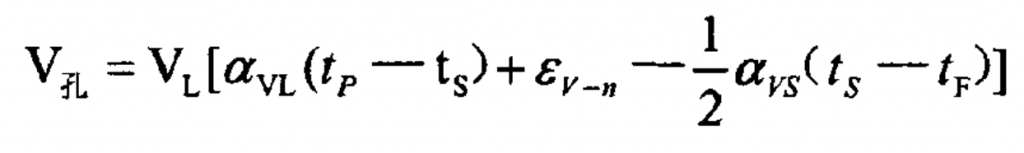

The defect volume of shrinkage casting is the difference between the overall volume of the casting and the metal volume, that is:

When the casting continues to cool, the volume of shrinkage casting defects decreases, but the percentage relative to the casting volume (the relative volume of shrinkage casting defects) can be considered as unchanged.

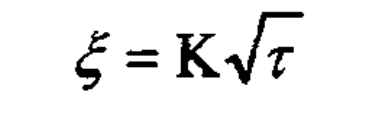

If the influence of pouring time on the defect volume of shrinkage casting is considered, the thickness of solidification layer on the bottom of casting after mold filling is calculated by square root law ζ For:

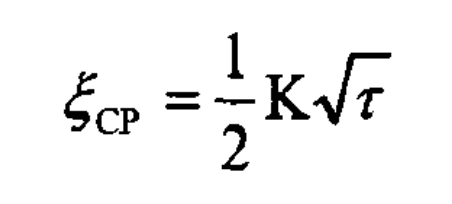

And the casting surface is just full, ζ Item = O, so the average solidification layer thickness on the casting surface ζ CP is:

Where:

K – solidification coefficient;

τ— Pouring time.