1. introduction to valve body parts

The valve body studied in this subject is a main part of the valve. It is mainly used to regulate or cut off the flow of various media on gas, natural gas, water supply and drainage, liquefied petroleum gas and other pipelines to prevent media leakage. Therefore, it is usually necessary to pressurize the product (5MPa pressure) to ensure the compactness of the internal organization.

2. Characteristics of valve body parts

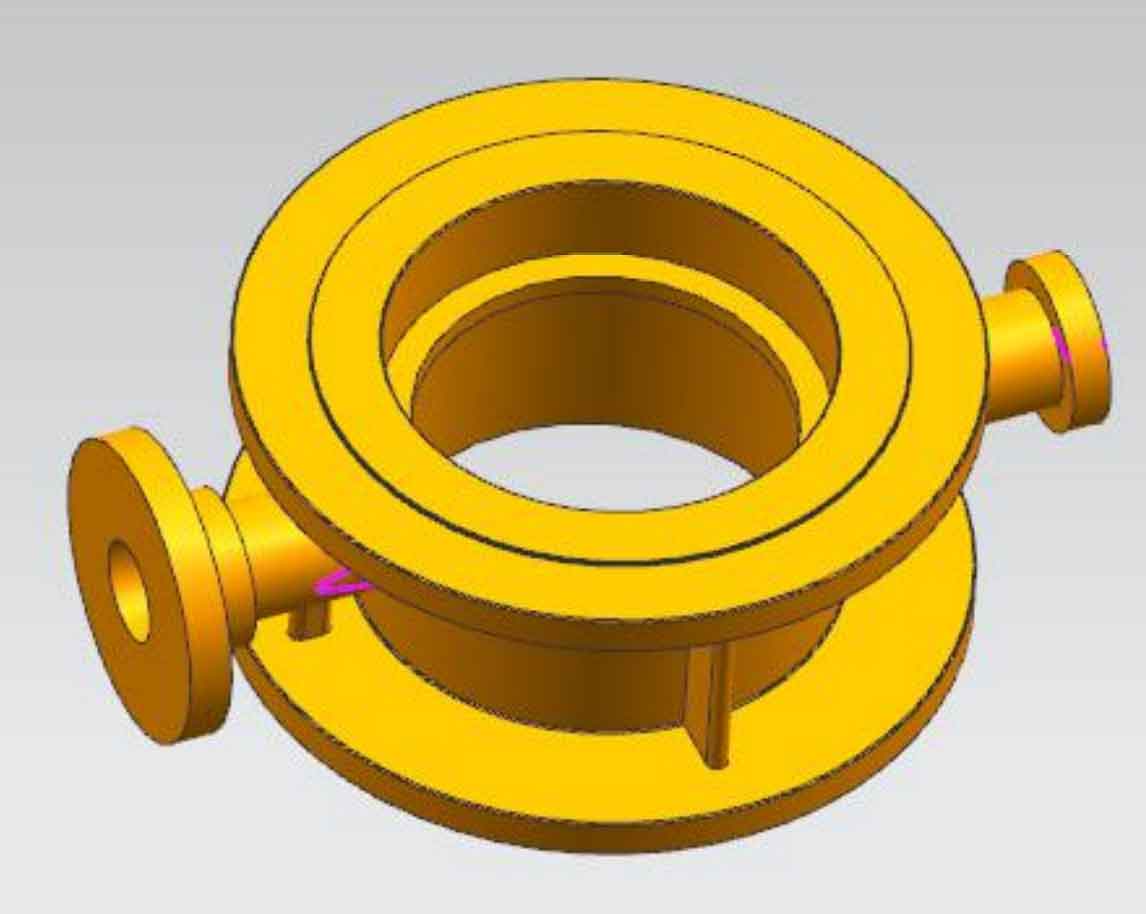

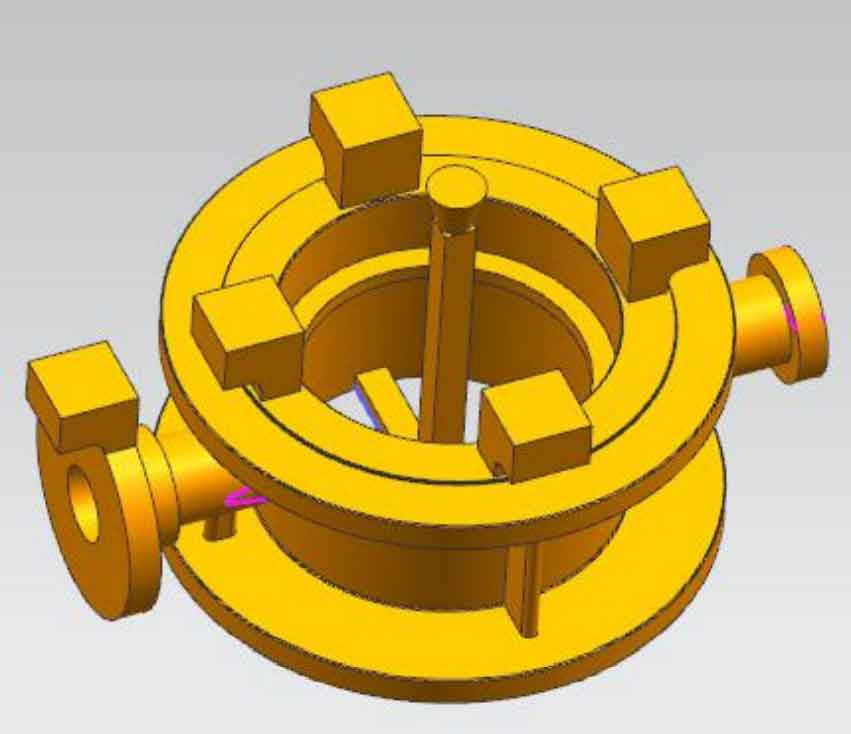

Figure 1 is the three-dimensional model diagram of the butterfly valve body studied in this subject, and Figure 2 is the solid diagram of the butterfly valve body. The outline dimension of the butterfly valve body is 460mm × 340mm × 150mm, weight about 329n. The material of the valve is zg230-250 (ZG25). It is observed from the above figure that the casting structure is similar to shell parts, with large middle cavity and large outer contour size. The longitudinal section of the casting is I-shaped, and there are four evenly distributed ribs on the cylinder wall. The structure seems simple, but there are many geometric hot joints. On the whole, the wall thickness is uniform, the maximum wall thickness is 25mm and the minimum wall thickness is 10mm. Technical requirements: the internal structure of the casting shall be dense, the external surface shall be smooth, and there shall be no casting defects such as crack, cold shut, sand hole, sand hole, shrinkage hole, shrinkage porosity and air hole.

3. Initial process

The bottom casting gating system is used in the original process, and the metal liquid fills the cavity from bottom to top steadily from the bottom of the casting, so that the impact force on the foam pattern is small, and there is no phenomenon of excitation and low price. It also inhibits the gas volume of the gasification mold. At the same time, the rising direction of the metal liquid is consistent with the flow direction of the biogas produced by the foam pattern decomposition and gasification, which is conducive to the scum. The temperature distribution of molten metal after mold filling is not conducive to sequential solidification and riser feeding, but it can well prevent slag, and the gas in the mold cavity is easy to be discharged in sequence. Therefore, this gating system is more suitable for non-ferrous alloys that are easy to oxidize and steel castings with high requirements. The original process is shown in Fig. 3, with two internal sprues and two transverse sprues, and the cross-section size is 15 × 10mm; One sprue, cross section size 15 × 15mm, 250mm high, four concealed risers are placed above the four ribs, and one concealed riser is placed on the small ring on the left side of the casting, a total of five risers of the same size and shape.

4. Initial process parameters

The basic technological parameters are: pouring temperature is controlled at 1580 degrees Celsius, negative pressure is 0.05Mpa, polystyrene (EPS) used in foam pattern and density is 20kg/m3.