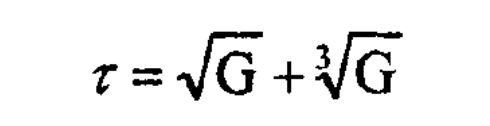

The sand casting time is determined as follows:

Where:

G – weight of sand casting (excluding pouring Li weight), unit: kg;

T – pouring time of sand casting, unit: s.

If the pouring time is equal to the pre eutectic shrinkage time, or the pouring time and the cross-sectional area of the ingate are determined so that the sum of the pouring time and the post feeding time (the period of time when the ingate remains unblocked after pouring) is equal to the pre eutectic shrinkage time, or the time after which the graphitization expansion generated by a part of the sand casting can compensate for the shrinkage of the rest, the feeding system can be used, Realize “riser free casting”.

The pouring time is determined according to the post repair time of gray cast iron and nodular cast iron. This links the pouring with the solidification shrinkage characteristics of the alloy. Due to the graphitization expansion of gray cast iron and nodular cast iron during solidification, they have the ability of “self feeding”. However, the expansion and contraction do not occur at the same time. The pre eutectic shrinkage (the sum of liquid shrinkage and primary austenite shrinkage) comes first and the graphitization expansion comes later. Generally, the ability of “self feeding” cannot be fully utilized.

For general sand castings, especially large sand castings, under the condition of ensuring sufficient residual head, the gating system with “large flow rate (kg / s) and low flow rate (cm / s)” should be used to facilitate rapid and stable filling.