1. Test process parameters

Three nodular iron castings were tested and poured. The main parameters during the test are: the tapping temperature of molten iron is 1492 ℃; Pouring temperature: 1386 ~ 1362 ℃; The pouring time is 21 s, 18 s and 20 s respectively; The pouring temperature of Y-shaped test block is 1351 ℃.

2. Mechanical properties

| Tensile strength / MPa | Yield strength / MPa | Elongation (%) | Hardness (HB) |

| 560 | 370 | 12 | 179 |

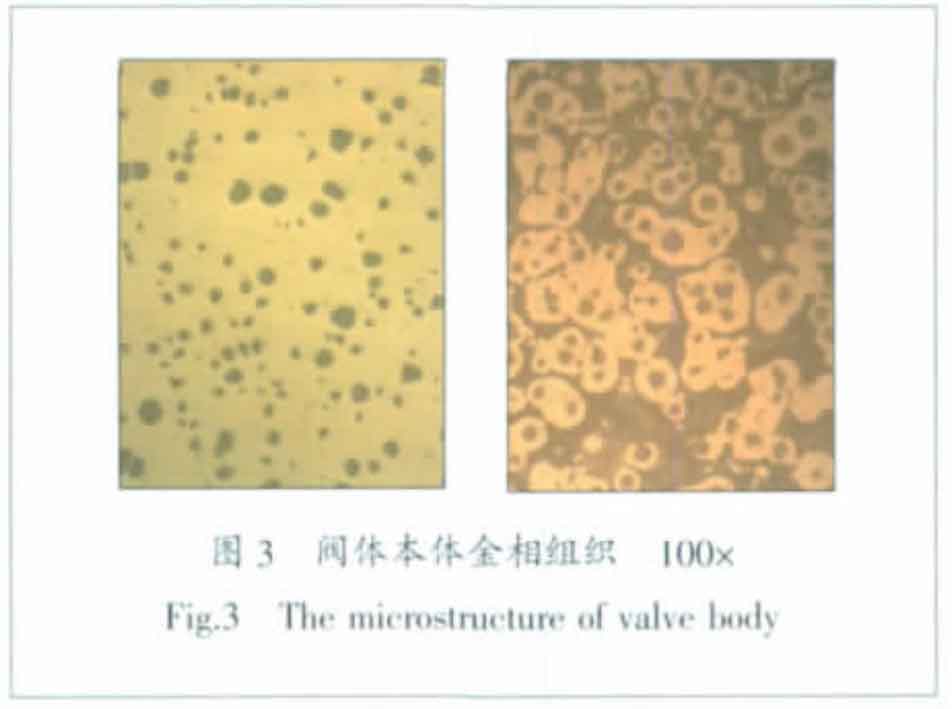

The performance test of Y-shaped test block is carried out. The test results are shown in the table, and the metallographic structure of the body is shown in Figure 3. According to the performance test results, it can be confirmed that the smelting process and pouring process can meet the requirements of nodular iron castings, which is reasonable and feasible.

3. Shrinkage

Dissecting the nodular iron castings, the actual measured shrinkage rate of nodular iron castings is: within the size range of 120 mm shown in Fig. 1, the shrinkage rate is about 0.35%, and that of other parts is about 0.68%, which is basically consistent with the parameters selected in the design. Through marking inspection, the machining allowance of each part is within the required range of design control.

4. Internal quality

Through the slice inspection of nodular iron castings parallel to the axis of valve hole, the section structure of nodular iron castings is dense without shrinkage and porosity. It is verified that the design scheme of gating and riser system process is reasonable. After shot blasting and inner cavity shot blasting, the inner cavity surface of nodular iron castings is smooth and free of defects such as sand sticking, burr and seam.