Since the sand casting material is aluminum alloy ZL105, an open gating system is adopted. It has the following characteristics: a straight < a cross < A, and its flow blocking section is in the sprue. After pouring, the mold filling is gentle and the scouring force on the mold cavity is small. It is suitable for sand castings that are easy to oxidize such as non-ferrous alloy.

Using the section ratio design method, according to experience, set the predetermined section ratio a straight: a cross: a inside = 1:2:4, and calculate the cross-sectional area of sprue and the cross-sectional area of sprue. The cross-section shape of the runner adopts trapezoidal section, which can reduce the heat loss and facilitate the mold processing.

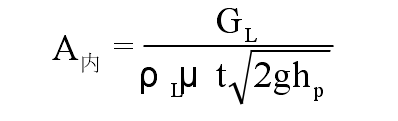

Calculation formula of sprue area in sand casting:

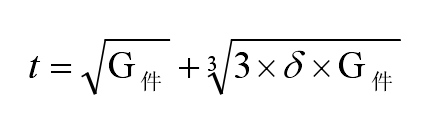

Calculation formula for pouring time of sand mold casting:

Where, a is the total cross-sectional area of the ingate, and GL is the total mass of the molten metal flowing through the resistance section of a, L ρ Is the density of liquid metal (kg / cm-3); μ Is the flow loss coefficient; T is the pouring time; G is the acceleration of gravity;

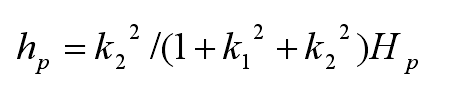

4 unit sand casting gating system:

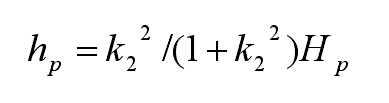

3 unit sand casting gating system:

Where: K1 is the area ratio of sprue section to cross sprue section; HP is the average static head height.

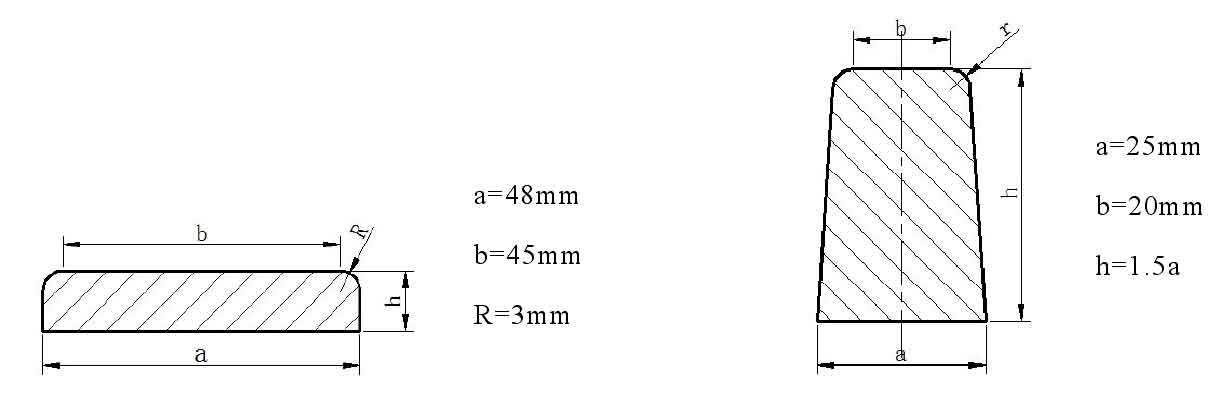

The flat internal sprue shall be selected, and the temperature difference and solidification sequence shall be adjusted by means of dispersion, uniformity and increasing its number to prevent slag absorption by liquid metal. According to the calculation, the cross-sectional area of the ingate is obtained. The cross-section of a single ingate is shown in figure (a). Trapezoidal cross-sectional area is selected for the cross runner, which can reduce heat loss and facilitate mold processing. The cross-section is shown in figure (b).