The production process of nodular cast iron to be designed in the experiment mainly includes melting process, molding process, spheroidizing treatment process, inoculation treatment process, pouring process and heat treatment process.

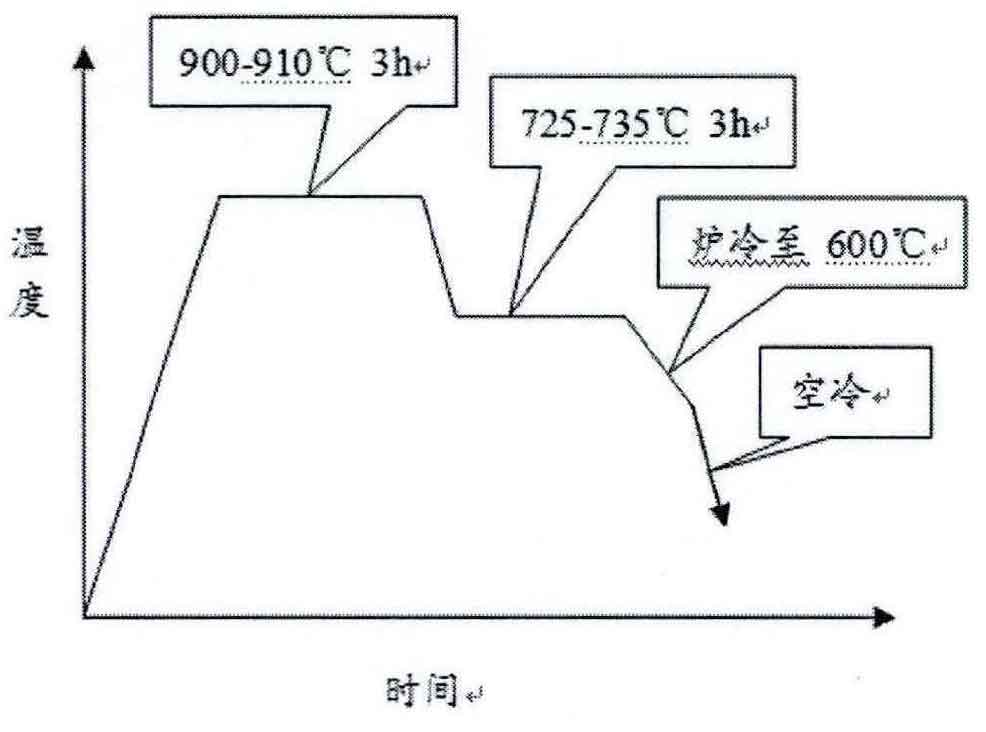

In the melting and pouring equipment of nodular cast iron, at the initial stage of the experiment, tons of medium frequency induction furnace was used for melting, and kg dam type spheroidizing treatment bag was used for spheroidizing and pouring. In the later stage of the experiment, tons of medium frequency coreless induction furnace was used for melting, and tons of dike type spheroidizing treatment bag was used for spheroidizing and pouring. The raw materials selected for smelting shall be clean and rust free, and shall be accurately weighed according to the charge ratio. Phenolic resin sand is selected as the molding process of nodular cast iron. Cold iron shall be added at the thick hot joint of nodular cast iron to avoid casting defects. The spheroidizing process adopts the impulse method, the particle size of the spheroidizing agent is 5-25mm, and the spheroidizing reaction time is controlled in 1-2 minutes. The inoculation treatment process adopts the secondary inoculation method. The inoculant is divided into three parts and added at the bottom of the package, the iron tapping groove and the gate cup respectively. The particle size of the inoculant at the bottom of the package and the iron tapping hole is 3-8mm and that at the gate cup is 0.5-2mm. Controlling the tapping temperature of molten iron at 1550-1520 ℃, too high or too low tapping temperature will affect the connection of subsequent links. Control the pouring temperature at 1350-1390 ℃, and shorten the pouring time as much as possible. The 1200 ℃ box type resistance furnace is selected as the heat treatment equipment, and the high and low temperature two-stage graphitization annealing process is selected. The specific parameters are shown in Figure 1.

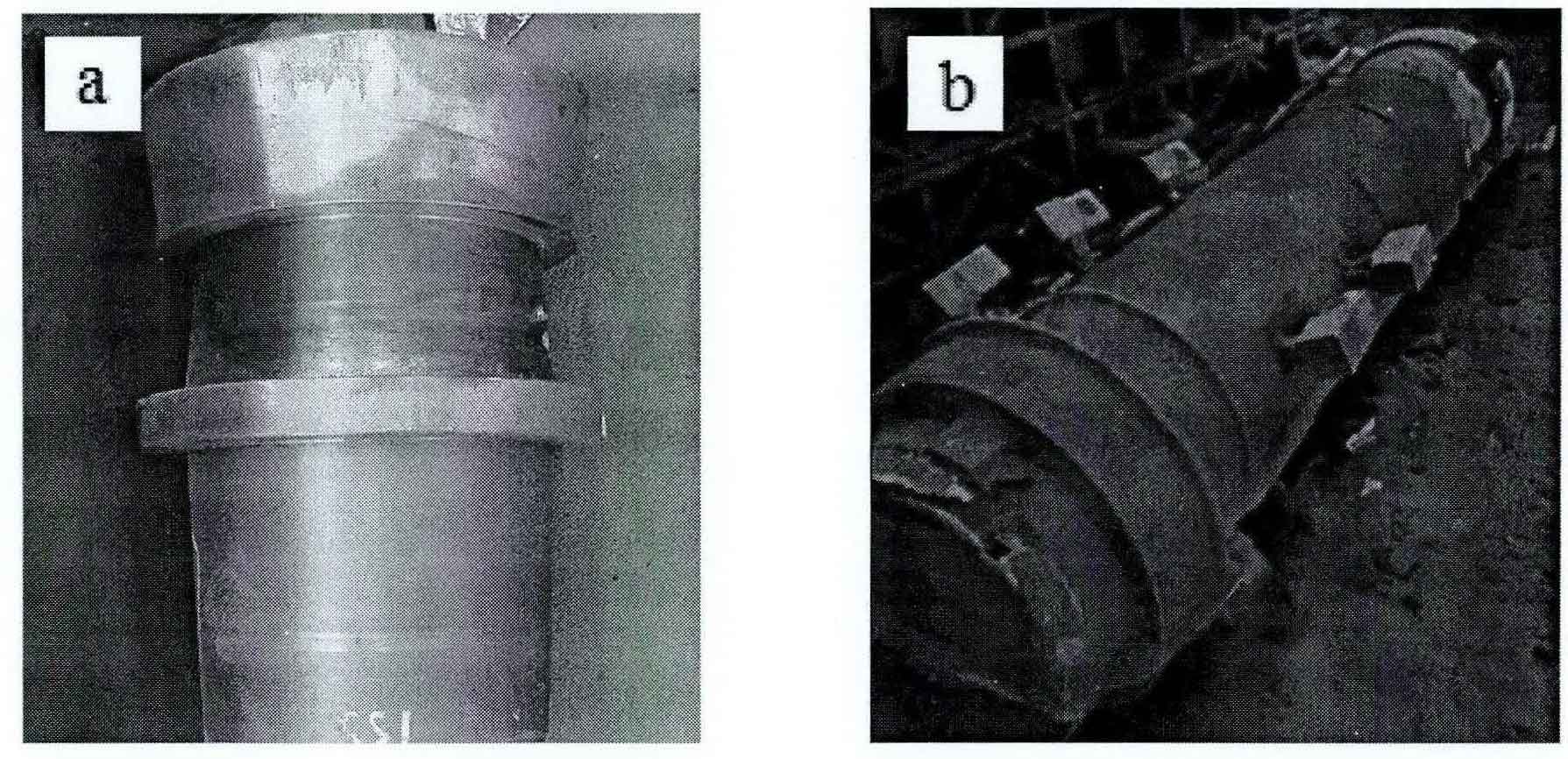

Through the design of production process, nodular cast iron as shown in Figure 2 was produced experimentally. Among them, figure 2a is the actual diagram of the finished nodular cast iron in the early stage of the experiment. Its structure is cylindrical, with a gross weight of about 200 kg and a wall thickness of 30-50mm. Fig. 2b is the actual drawing of the blank of simulated nodular cast iron in the later stage of the experiment. Its structure is also cylindrical, with a gross weight of about 3 tons and a wall thickness of 50-70mm.