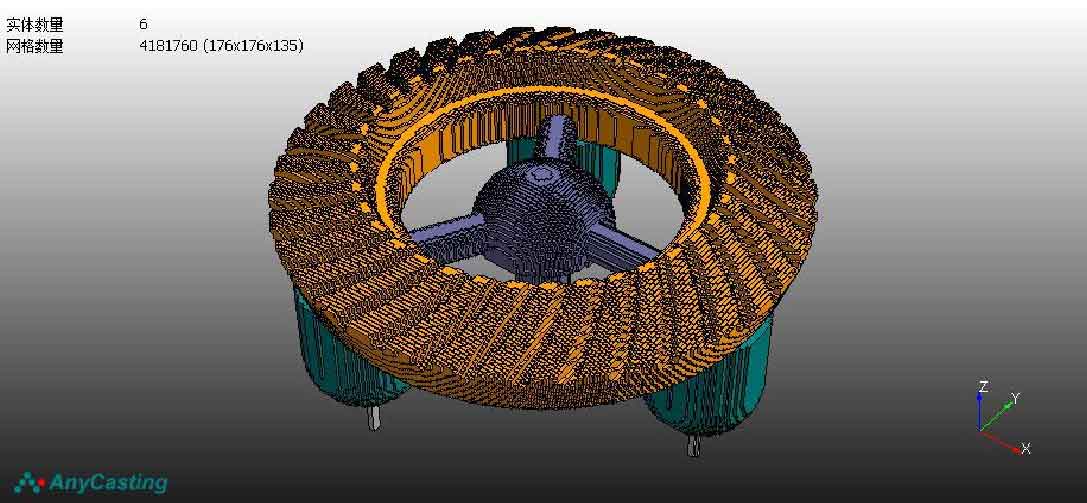

In CATIA three-dimensional modeling software, save the component digital models of sand casting and gating system as STL format and import them into AnyCasting software preprocessor any pre respectively. Define each group of meta types in the set entity option; Determine the size and range of sand mold; In order to improve the calculation efficiency and ensure the simulation results of gear blank casting, the variable mesh generation method is adopted and the number of meshes is densified locally in the sand casting, and the number of meshes is 4181760. It can be seen from the grid division effect diagram of the Pouring Scheme in the figure that the geometry is well preserved after the grid division of the tooth part with the most complex shape. It shows that the meshing method and quantity are appropriate.

After dividing the grid, set the task design as coated sand casting (mold filling analysis and heat / solidification analysis before and after mold filling); Define the material properties of each component: sand mold quartz sand, gating system 20CrMoH, insulation sleeve flue ash; Define the heat exchange coefficient between components in the heat conduction model: the heat exchange coefficient between air and other components is set as 5W / m2 K, and the heat exchange coefficient between sand mold and casting, riser and sprue is 500W / m2 K; The liquidus temperature of 20CrMoH is 1511 ℃. Because the gear sand casting is a complex small part, it is preliminarily decided to set the pouring temperature of liquid metal in the gate conditions to 1650 ℃; When the pouring speed is set to 1m / S (the corresponding pouring time is 2.38s, which is consistent with the theoretical calculation value); The gravity direction is set as the positive direction of Z axis according to the modeling situation; Activate the shrinkage model and oxidation / slag inclusion model in the optional module to analyze and predict the possible sand casting defects of sand castings.

To sum up, after setting the process parameters and boundary conditions of the pouring scheme, save the pre-processing file and call anysolver for calculation.