The sand casting material of gearbox shell is ZL114A aluminum alloy, with high requirements for mechanical properties: tensile strength ≥ 320MPa, yield strength ≥ 280mpa, elongation ≥ 6%; The chemical composition and casting quality of sand castings shall meet the technical requirements of class I sand castings in GB / t9438-2013 aluminum alloy castings, and 100% X-ray inspection shall be carried out. Cracks are not allowed in the sand castings, and the internal defects shall meet the provisions of the designated parts of class I sand castings in hb6578 standard for pinhole inspection of castings, Chromic acid processing and repair of the diaphragm are not allowed.

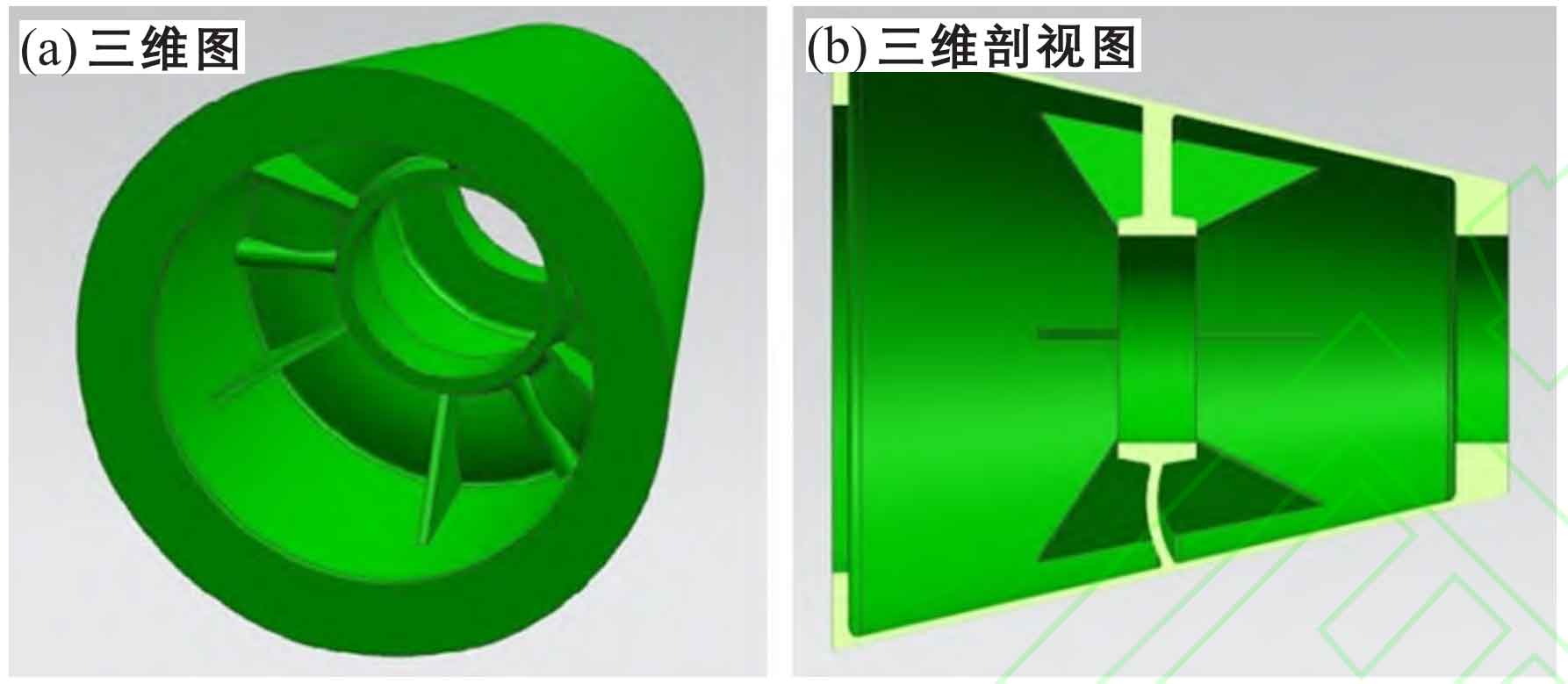

After heat treatment and before machining, the surface of sand castings needs sand blasting and fluorescent penetrant testing; After the machining of sand castings, the inner cavity shall be subject to kerosene leakage detection without leakage. In addition, the oil circuit of the gearbox shell needs aviation 4450# lubricating oil for tightness test. The oil pressure is 0.35Mpa and the pressure is maintained for 15min without leakage. The structure of the sand casting of the gearbox shell is shown in Figure 1. The shape is a round platform cylinder, and the inner wall is provided with diaphragm, stiffener, oil circuit, boss and middle annular structure. The overall dimension of sand casting shall be 600 / 1200 × 1300 mm, the main wall thickness is 14 mm, the partition wall thickness is 20 mm, the stiffener wall thickness is 18 mm, the middle annular structure wall thickness is 40 ~ 50 mm, and the thickest part is 90 mm. It is a large complex sand casting with uneven wall thickness.