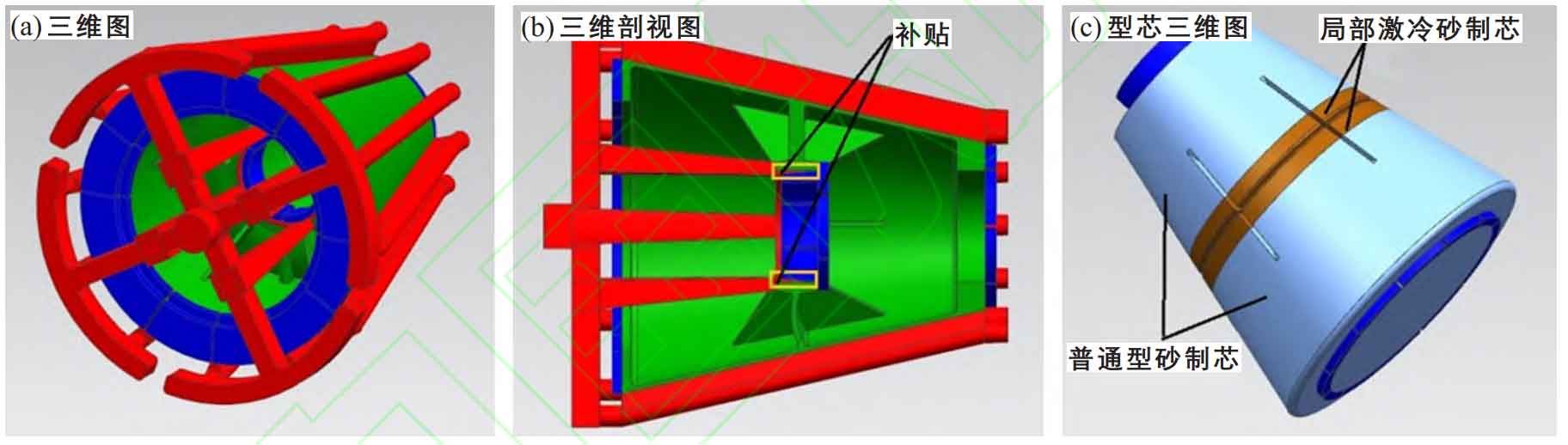

At the place where the upper and lower cores form a diaphragm, chromite ore sand is used to replace ordinary silica sand for core making, and silica sand is used for other parts of the core. Chromite ore is a kind of chilled sand. It has large heat capacity and thermal conductivity, which is several times larger than silica sand. It can be placed in a part of the mold or core, and can also be added in the molding sand. It is especially suitable for the parts where it is difficult to place chilled iron in the mold and core. It can replace chilled iron to accelerate the cooling speed at the diaphragm, oil circuit and boss, so as to realize simultaneous solidification. In addition, a series of chilled sand such as chromite ore sand is used as molding material, which has similar concession with ordinary molding sand and does not affect the shrinkage of sand castings (as shown in the figure).

A subsidy is added on the side of the middle annular structure and a wedge-shaped feeding channel is set (Fig. (b)). Cold iron is placed on the top and side of the middle annular structure to create an artificial end area, so as to improve the effective feeding distance of the riser. In addition, the side cold iron uses wedge-shaped cold iron to increase the temperature gradient in the height direction of the middle annular structure during solidification, so as to establish good feeding conditions for sand castings during solidification, realize the sequential solidification of the middle annular structure from top to bottom, and finally change the shrinkage porosity into shrinkage cavity, so that the shrinkage cavity is concentrated in the lower riser of the middle annular structure. The process parameters of sand casting are the same as those of the original casting process scheme.

After the improvement of the process scheme, a sand casting of gearbox shell was produced, and the internal quality of the sand casting met the technical requirements by X-ray detection.