For many years, castings and forgings have been used as the product parts of ZHY Casting excavator. The new technology of investment casting was started. In recent years, the product varieties have been gradually expanded, and the product output has been continuously improved. The weight of precision castings has increased from 0.3KG to 0.6kg, and the varieties have increased from several to nearly 100. Due to the development of precision casting, it not only saves a lot of steel, but also reduces the workload of machining. The workers and masters praised that precision casting is good, saving labor, time and materials.

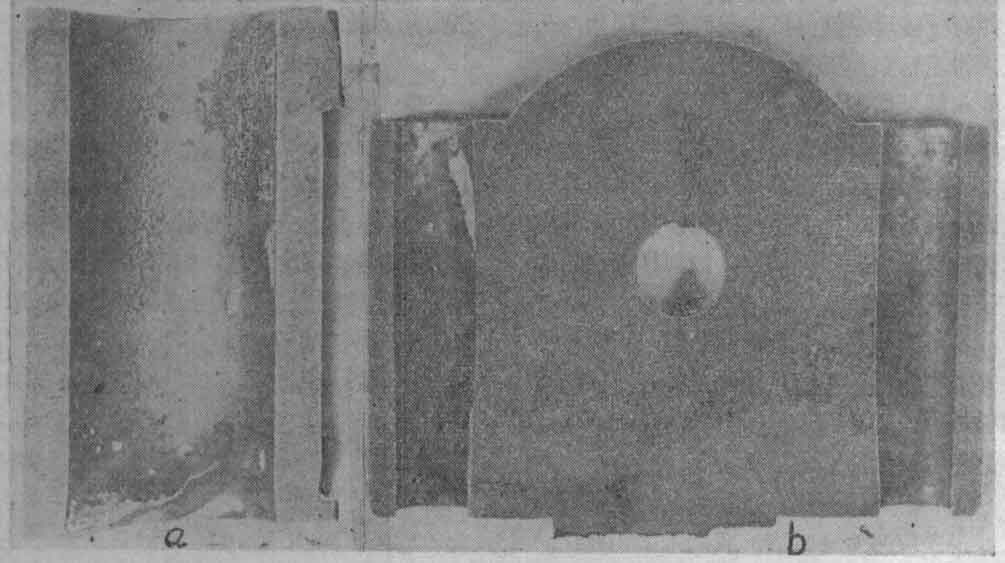

At the beginning of investment casting, ZHY Casting mainly produces tractor accessories, it was applied to excavators in June 2010 and achieved good results. The materials can be saved by half, the processing hours can be shortened by 80% – 90%, and the processing procedures can be reduced by 2 / 3. In production, we have dissected the cylinder block and tested it by low-power acid leaching. The central shrinkage porosity and inter branch shrinkage porosity have reached grade I, as shown in the figure. Compared with ordinary steel castings, the shrinkage porosity tendency is greatly reduced.

(1) The quality of precision castings is unstable and the waste products fluctuate greatly. The main reasons for scrapping are shrinkage crack and uneven surface. Therefore, how to improve the surface and overall strength of the shell and choose a reasonable pouring process are the main measures to reduce waste products.

(2) At present, the intensity of physical labor is high, and artificial wind is also used to hang sand. Therefore, efforts are being made to reduce physical labor, improve production efficiency and realize large mechanical hanging sand.

(3) The shell making room shall be equipped with a heating device to keep the room temperature above 18 ° C in winter, so as to improve the product quality.

(4) We think that investment casting has great potential to serve the parts of excavator products. It can not be limited to the parts replaced by casting. It should develop in the direction of replacing welding with casting and forging with casting. This is a fast, good and economical way.

(5) Our cost is still on the high side, so how to try to use inferior materials instead of superior ones is a measure to reduce costs.

(6) A new process that can both harden and dehydrate rapidly should be explored, which is one of the key measures to shorten the precision casting cycle and improve the output.