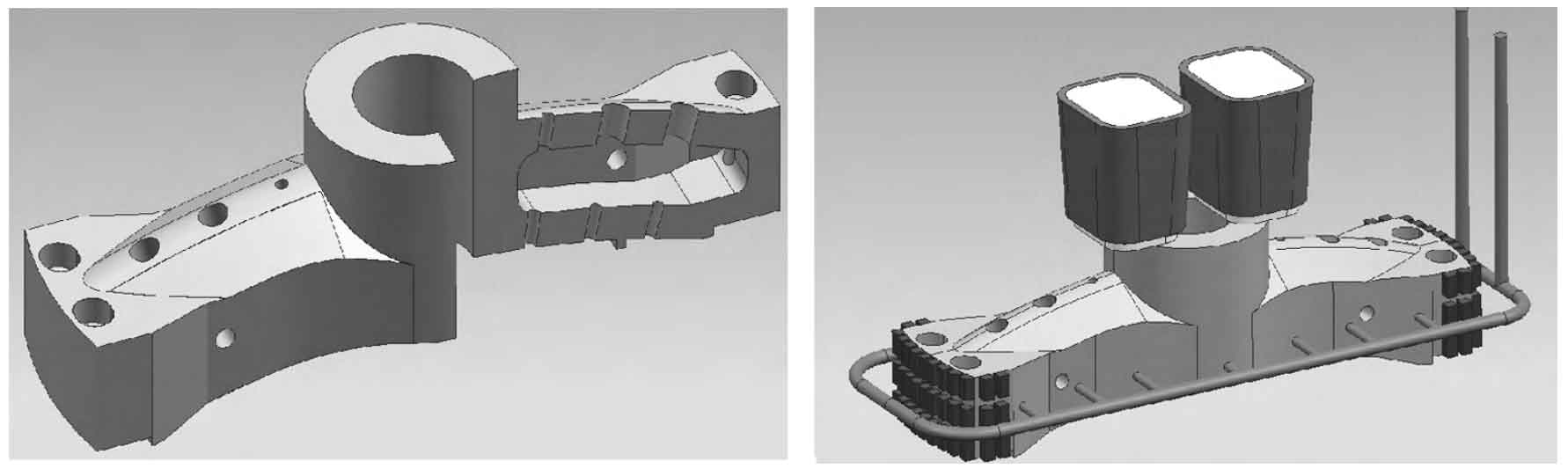

Figure (a) shows the beam casting of the crusher (the right side of the casting is the cutting part). The material is zg275-485 and the mass is 30 t. The wall thickness of the casting is thick and the solidification time is long. It is easy to form shrinkage defects at the end arm of the casting during solidification.

(b) Original process drawing of beam of rotary crusher

Figure (b) shows the original casting process. Two open top heating risers are added at the top of the central shaft of the casting for feeding liquid metal. Because the casting is long, adding cold iron at both ends of the casting for quenching can increase the solidification speed at both ends. The total weight of this process is 55 t.

The yield of the process is 68%. Using this process, in the actual production, it is found that the flaw detection is unqualified on both sides of the beam, so there is a great tendency of shrinkage cavity and porosity casting defects in this part.