1. Modeling

Steel casting material ZG275-485; The pouring temperature is between 1550 ~ 1560 ℃, and the ambient temperature is 25 ℃; The pouring time is more than 4 min. Sand mold gravity casting is adopted, and the molding sand is grease hardening resin sand.

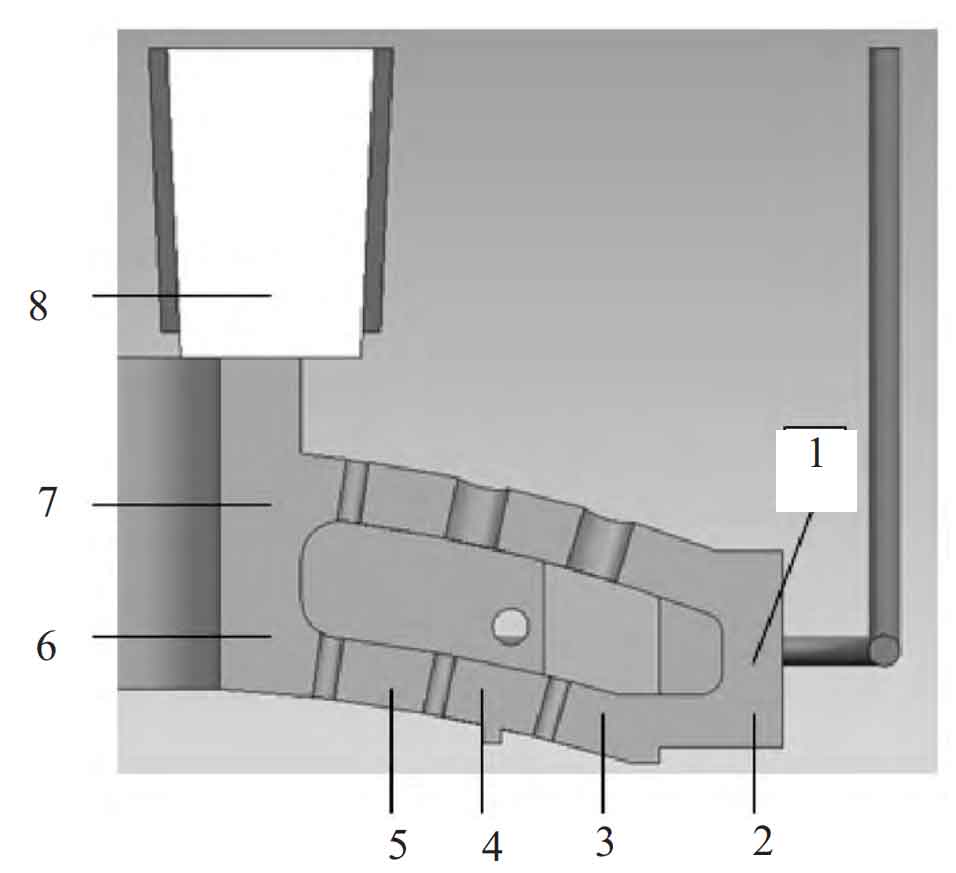

The niyama criterion shows that the ratio g / R1 / 2 of the temperature gradient g and the quadratic root of the cooling rate r at a certain point in the steel casting is the niyama function value of that point. For steel castings, when the niyama function value of a certain area is less than 1, shrinkage cavity and porosity casting defects will occur in this area during solidification. Therefore, according to the niyama criterion, it is necessary to calculate the niyama function value of each region of steel castings. Through simplified treatment, the average distribution point from the tail chilling zone of steel castings to the riser is selected as the representative to study the overall distribution of niyama function value. Because the beam has a symmetrical structure, after simplification, select 1 / 4 of the longitudinal section of the steel casting to establish the model, and select 8 position nodes on the section in turn, with node numbers of 1 ~ 8 respectively, as shown in Figure 1.

2. Temperature field simulation

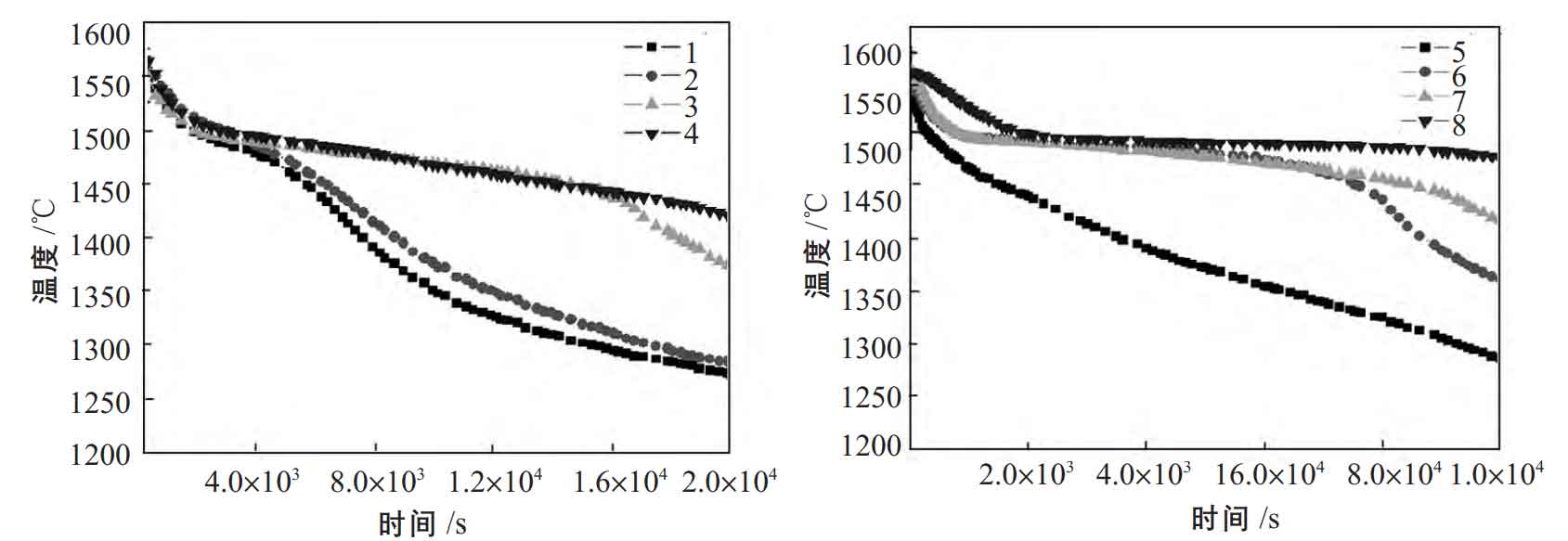

The casting process of steel castings is numerically simulated by ProCAST software. And draw the temperature change curve with time for the eight locations selected in Fig. 1, as shown in Fig. 2 (a) and (b). Compared with points 1 and 2, the temperature change trend of points 5 ~ 8 is gentle in the first 20000 s of cooling. Therefore, in order to more comprehensively observe the change trend of cooling rate at 5 ~ 8 points, the time range selected at 5 ~ 8 points was extended during drawing. As can be seen from Figure 2 (a), the cooling of points 1 and 2 is faster, while the cooling of points 3 and 4 is slower. Cooling time reaches 2 × At 104 s, the cooling rate at 5 points is significantly higher than that at 6, 7 and 8 points, as shown in Fig. 2 (b).

According to the temperature drop (temperature gradient) curve in Figure 2, it basically meets the requirements of sequential solidification. Therefore, the causes of shrinkage cavity, especially shrinkage porosity, of steel castings in the actual production process cannot be given. Therefore, it is necessary to compare the temperature gradient with the cooling rate. According to the niyama criterion, the change relationship between the temperature of each point at the end of solidification and time is selected to calculate the cooling rate, and the temperature gradient at this temperature is calculated from the ProCAST simulation results. The generation of shrinkage cavity and porosity is determined by the relationship between temperature gradient and cooling rate.

3. Niyama criterion value and discussion

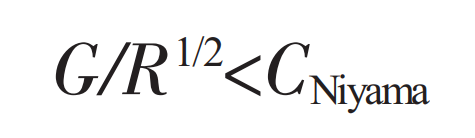

According to Niyama Criterion Formula:

In the formula: G is the temperature gradient, unit (℃ / cm), which can be obtained from the temperature field simulation results of ProCAST software; R is the cooling rate of solidification temperature in a certain area, unit (℃ 1 / 2 / Min1 / 2), which can be obtained from the temperature curve of 8 points with time; Cniyama is the calculated value of niyama function criterion, unit (℃ 1 / 2min1 / 2cm-1). Steel castings are generally 1 ℃ 1 / 2min1 / 2cm-1. The research shows that it is appropriate to take 1.1 ℃ 1 / 2min1 / 2cm-1 for large parts and 0.8 ℃ 1 / 2min1 / 2cm-1 for small parts.

The steel castings in this study are selected as 1.1 ℃ 1 / 2min1 / 2cm-1. Table 1 shows the calculation results of g / R1 / 2 of steel castings at 8 points.

| Point | Temperature 1 / ℃ | Temperature 2 / ℃ | Temperature difference / ℃ | Time difference / min | Cooling rate r1/2/ (℃ 1/2/min1/2) | Temperature gradient g / (℃ / cm) | G/R1/2/(℃1/2/min1/2cm-1) |

| 1 | 1508 | 1437 | 71 | 79.22 | 0.95 | 4.08 | 4.29 |

| 2 | 1521 | 1429 | 92 | 97.23 | 0.97 | 2.96 | 3.05 |

| 3 | 1497 | 1411 | 86 | 251.97 | 0.83 | 1.53 | 1.84 |

| 4 | 1478 | 1403 | 75 | 238.40 | 0.64 | 0.67 | 1.05 |

| 5 | 1503 | 1421 | 82 | 408.42 | 0.59 | 1.02 | 1.73 |

| 6 | 1517 | 1438 | 79 | 1261.76 | 0.26 | 0.68 | 2.61 |

| 7 | 1498 | 1424 | 74 | 1219.81 | 0.24 | 0.49 | 2.04 |

| 8 | 1512 | 1444 | 68 | 1218.26 | 0.23 | 0.37 | 1.61 |

It can be seen from table 1 that the criterion values of positions 1 and 2 are the highest, which is due to the addition of cold iron at the end of the steel casting to form chilling, which relatively increases the temperature gradient in the end area and will not produce defects in this area. Positions 3, 4 and 5 are far away from the end of the steel casting and the riser, and the niyama function criterion value in this area is small, only about 1 ℃ 1 / 2min1 / 2cm-1. The complete liquid metal feeding cannot be obtained during the solidification process, resulting in shrinkage cavity and porosity defects after the solidification, especially near position 4. Due to the heat preservation, heating and heat conduction of the riser, the cooling speed at 6, 7 and 8 at the lower end of the riser is very small, which relatively improves the niyama function criterion value, and there are no shrinkage defects in these areas.