The lost foam casting method is flexible and convenient in modeling and pouring, especially for products with complex structure. lost foam casting products have good appearance quality and high precision, which are adopted by more and more production enterprises. However, there are also many defects in the lost foam casting, among which the carburization of steel castings, especially low carbon steel, seriously restricts the application scope of the lost foam casting.

The carburization of lost foam casting steel castings has always been the key research direction of the application of lost foam casting in steel castings. Carburization of steel castings will make the composition of castings fail to meet the requirements. With the increase of carbon content, the reduction of section shrinkage and elongation of steel castings will be reduced, the plasticity and toughness will become worse, and the processability and welding performance will become worse.

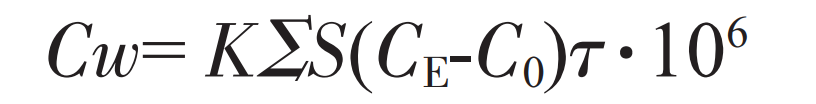

The fundamental reason for carburization of lost foam casting steel castings is that the foam pattern in the mold is cracked and decomposed under the action of high-temperature molten steel during the pouring and forming process of molten metal, resulting in a large amount of free carbon and hydrocarbons. During the pouring and condensation process, the molten steel is always surrounded by the decomposition products of the pattern, resulting in carburization of steel castings. The mass transfer equation of carbon entering steel castings is:

Where, CW is the carbon content of the casting,%; S is the contact area between the thermal decomposition product of the pattern and the molten metal, m2; CE is the carbon content of pyrolysis products,%; C0 is the original carbon content of molten metal,%; K Σ Is the mass transfer coefficient, s · m-2; τ Is the contact time between the metal liquid and the pyrolysis product, S.

It can be seen from the formula that the greater the concentration difference (ce-c0) between liquid metal and EPS pyrolysis products, the larger the contact area s and the longer the contact time τ The longer, the more carbon.

The carburizing defects of lost foam casting are mainly divided into surface carburizing, volume carburizing and local carburizing. The surface carburization defect is mainly that the solid carbon adsorbed by the coating layer enters the surface of the steel casting during the solidification process of the steel casting, which increases the carbon content of the surface of the steel casting. The thickness of the carburizing layer is small, generally 0.1 ~ 0.3 mm, and the carburizing amount varies greatly, ranging from 0.01% ~ 0.10%.

When the volume carburization of steel castings is stable, it is only related to the carbon content difference between liquid metal and pyrolysis products, contact area and contact time. For steel castings with moderate wall thickness, when the mold filling of steel castings is stable, the difference of carburization value in each part of steel castings is small. Therefore, this feature can be used to produce steel castings with qualified composition.

Local carburization of steel castings mainly occurs when the steel castings are thick and the filling process is unstable. When the liquid metal is wrapped with solid and liquid patterns, it makes that part of the liquid metal contact with carburizing substances for a long time in the solidification process, and finally serious carburization defects occur. Moreover, local carburization often occurs in the thick hot spot of steel castings, resulting in product scrapping. For steel castings, the most harmful is the local carburization defect.

Since the carburization of steel castings comes from the foam pattern, if you want to reduce the carburization of steel castings, you must start with the foam pattern.