Process design is very important to the quality of sand casting. Even if other conditions are met, if the process design of sand casting is not good, it can not produce good products. The following is an analysis of the influence of the sand casting process design of the shell casting of our company on the product quality.

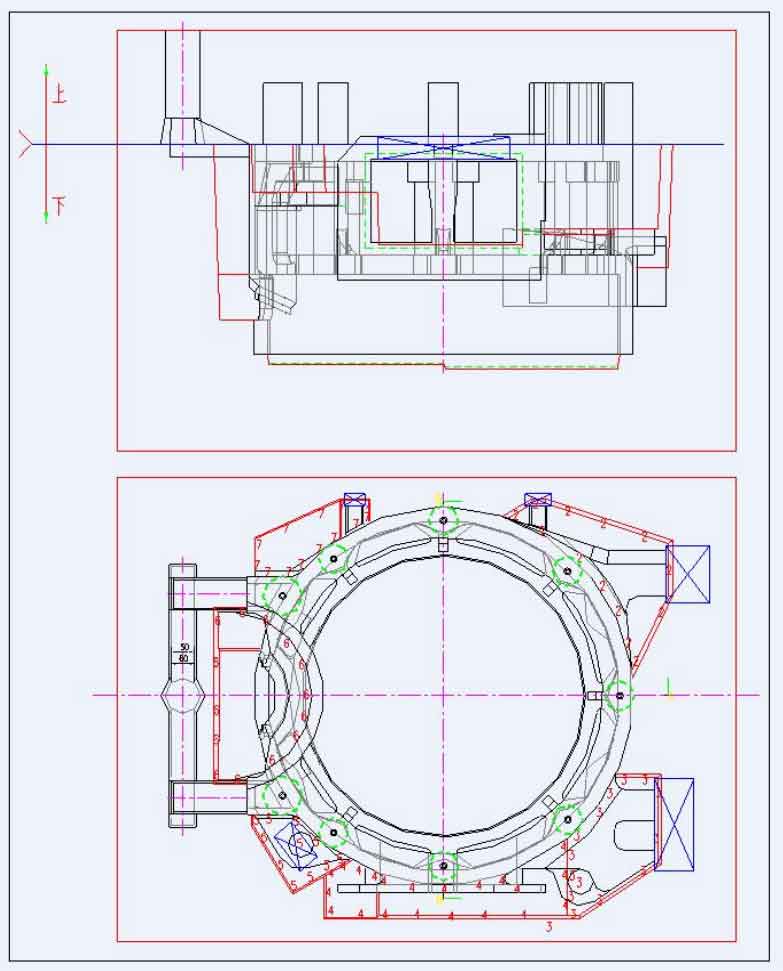

It can be seen from the sand casting process diagram of motor shell casting in Figure 1 that the parting surface is set at the top of the sand casting, and the gating system is top injection type. The two internal crossings are set at the column part with relatively thick sand casting, and multiple risers are set at the top, which leads to the heat concentration at the inner runner part and column top, which is basically the final cooling and solidification, so shrinkage cavities and cracks are easy to occur at this part.

It can be seen from Figure 2 that: 1# the four relatively large cold irons placed on the core are easy to form cracks around the cold irons due to the strong chilling ability of this sand casting process.

In addition, the designed pouring process also has a certain impact on the crack. For thin-walled sand castings, high-temperature fast pouring is required to make the solidification speed slow and uniform, so as to reduce the tendency of hot crack; For thick wall sand castings, if the pouring temperature is too high, it will increase the shrinkage area, so as to slow down the cooling speed, but promote the formation of hot cracks. Therefore, the thick wall sand castings should be poured slowly at low temperature. Because some parts of the motor shell are relatively thin and some parts are relatively thick, cracks are easy to form in high-temperature fast pouring and low-temperature slow pouring. The pouring temperature of the motor shell is set at 1590 degrees in the design, which belongs to high-temperature pouring, which increases the tendency to form cracks.