In sand casting production, it is often found that castings with sand inclusion, either inside or on the surface, are generally not treated or polished or repaired by welding, which will lead to scrapping in serious cases. Sand inclusion mainly includes the following forms:

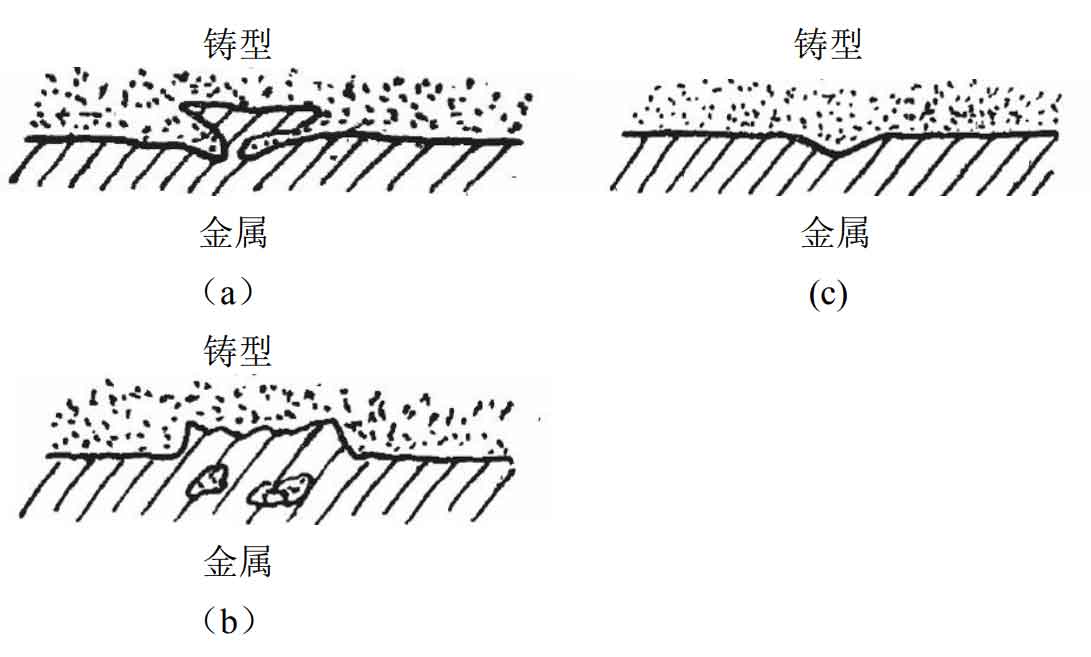

① The sand mold surface bulges and cracks locally, but the cracked and warped sand layer has not been separated from the sand mold body. After the metal liquid enters the sand mold gap, a raised scar is formed on the surface of the sand casting, its edge is separated from the sand casting body, and the middle part is connected with the sand casting, which is called sand inclusion, as shown in Fig. 1 (a).

② The warped sand layer of the sand mold is separated from the sand mold body, and the metal liquid flows into it to form a rough tumor like defect on the surface, which is called scar. The separated sand is sandwiched in the scar block or other parts to form sand holes, as shown in Fig. 1 (b).

③ The surface of the sand mold bulges locally, but there is no crack. At this time, a strip groove is formed on the surface of the sand casting, which is often called “rat tail”, as shown in Fig. 1 (c).

A hole in a sand casting where sand particles or sand blocks are wrapped inside or on the surface is called a sand hole. According to the location of sand holes, they can be divided into surface sand holes and internal sand holes. The sand holes on the surface of sand castings can be identified by visual inspection; The sand holes in sand castings shall be inspected by ultrasonic or radiographic inspection. Sand inclusion on the outside and inside of sand castings are shown in Figure 2 and 3