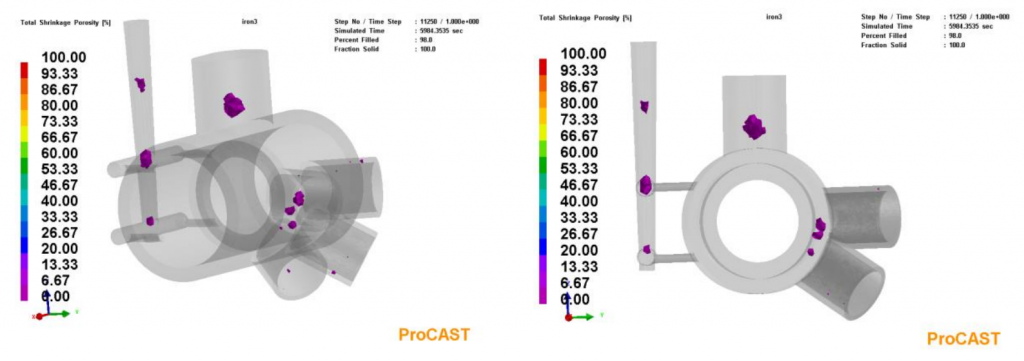

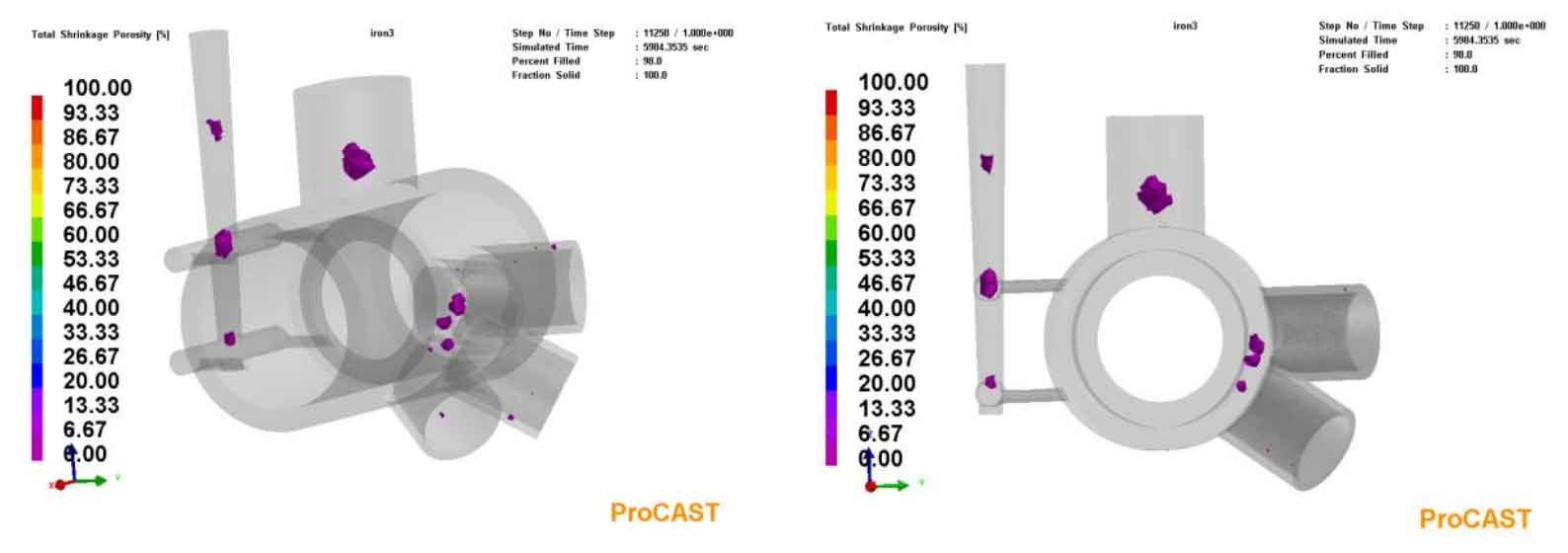

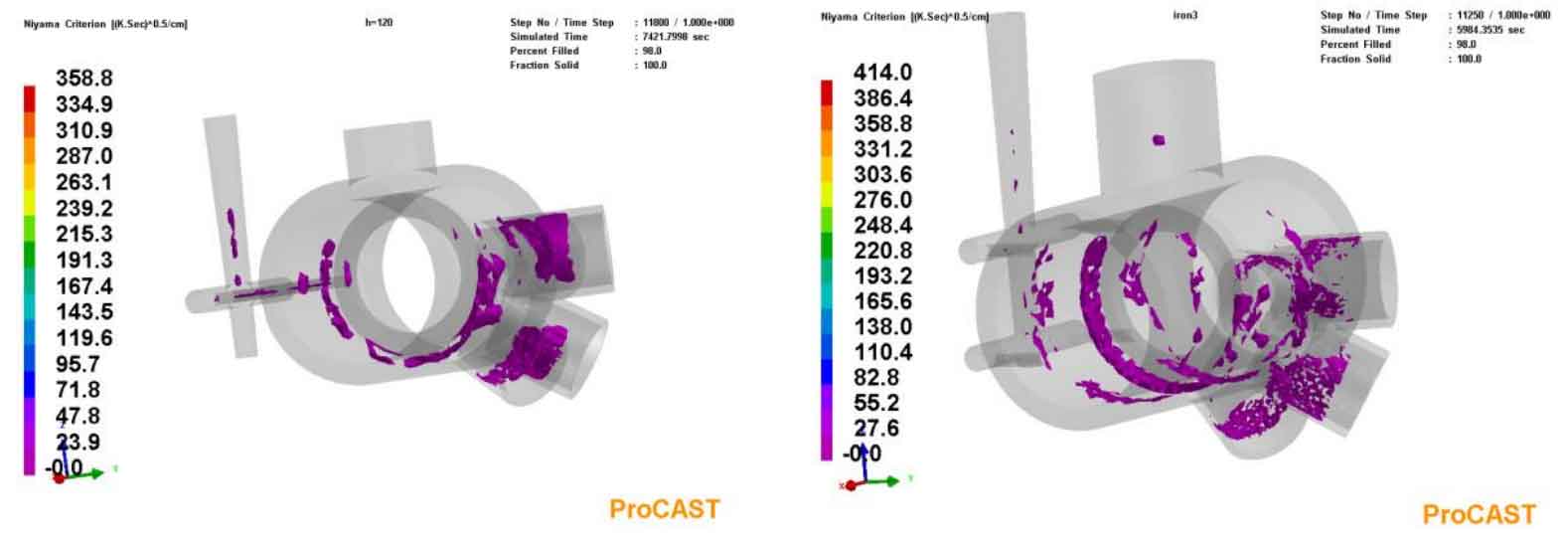

The orthogonal experiment will be designed, the riser height is set as the independent variable, and other process parameters remain unchanged. The shrinkage porosity prediction under different criteria is obtained by software.

Comparing the risers of two heights, it is found that the design of the riser still has a significant impact on the casting quality, especially in the area near the riser. From the simulation results, it can be seen that the shrinkage and looseness defect of the 120mm riser will be very obvious, and even affect the main pipe. The 285mm waist riser significantly reduces the casting defects near the riser and transfers the shrinkage defects to the inside of the riser, so as to carry out feeding well. The high riser pressure will make the steel castings more dense and of better quality. However, the effect of high riser on reducing shrinkage defects near stiffeners is not significant.