50KW medium frequency induction furnace was used for smelting in the test, with 25 kg charge per group.Proportioning principle: proportioning shall be carried out according to the actual requirements for the production of low carbon equivalent gray cast iron of corresponding brand. Raw pig iron, scrap steel and ferroalloy commonly used in production shall be selected as raw materials, and the chemical composition shall be determined by the chemical composition requirements of corresponding brand.

1.The scheme is proportioned according to the composition requirements of HT250. CE is about 3.78% and the wall thickness is less than 30mm.

2.Table 1 for the chemical composition requirements of the gray casting molten iron.

| Chemical compositio | C | Si | Mn | P | S |

| General range (%) | 3.0-3.3 | 1.5-1.8 | 0.8-1.0 | <0.2 | <0.12 |

| Selection (%) | 3.15 | 1.8 | 0.8 | <0.2 | <0.12 |

3.The charge of gray castings includes primary iron Q12, scrap steel, fesi75 and femn75. The chemical composition of the charge and the burning loss rate of main elements in the charge are shown in Table 2.

| Charge name | C | Si | Mn | P | S |

| Q12(%) | 4.4 | 1.1 | 0.3 | / | / |

| Scrap (%) | 0.2 | 0.4 | 0.4 | 0.02 | 0.02 |

| FeSi75(%) | / | 75 | / | / | / |

| FeMn75(%) | / | / | 75 | / | / |

| Burning loss rate in furnace(%) | 5 | 0 | 10 | / | / |

4.Use the selection method to mix the burden of gray castings. The preliminary mix is as follows (the iron charge is calculated as 25kg): Q12 pig iron 75% (18.75kg) and scrap steel 25% (6.25kg).

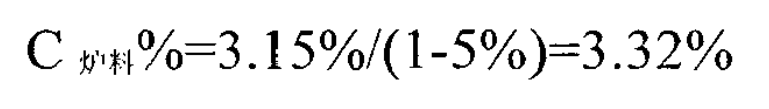

5 carbon content required for gray cast iron charge:

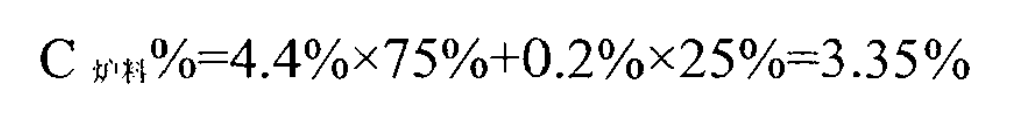

Carbon content of gray cast iron charge:

After calculation, the carbon content of gray cast iron charge is basically consistent with the required carbon content, so the proportioning proportion is appropriate and available.

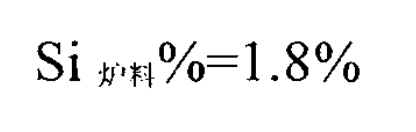

6.Check the silicon content of gray cast iron charge

Required silicon content of gray cast iron charge: since the burning loss of silicon in the furnace is basically zero during the training process of acid induction furnace, the required silicon content of gray cast iron charge is calculated according to the selected silicon content, that is:

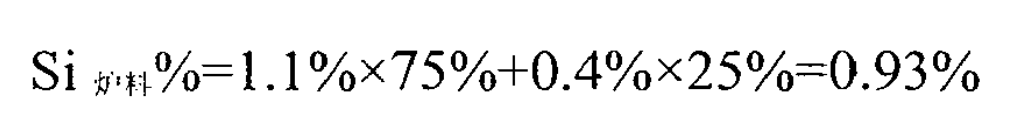

Silicon content of gray cast iron charge:

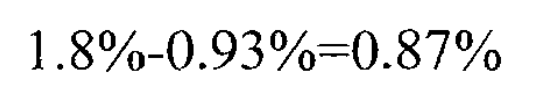

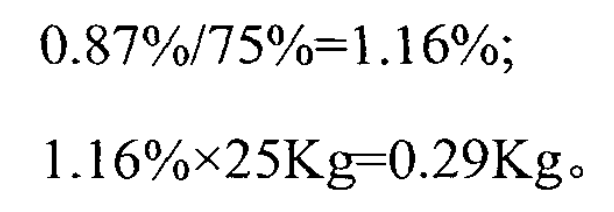

Amount of silicon still lacking in gray cast iron charge:

Silicon supplement with fesi75:

7.Calculate the manganese content in gray cast iron charge:

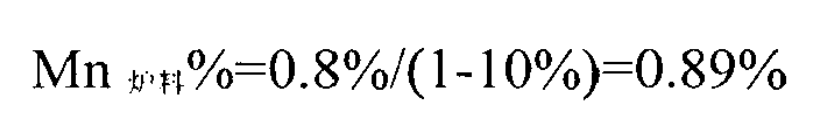

Manganese content required for gray cast iron charge:

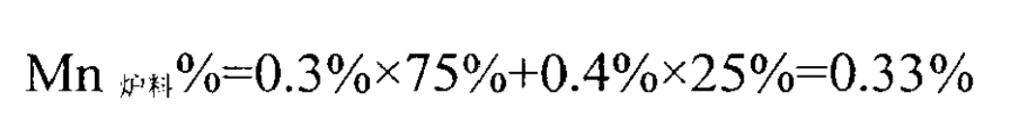

Manganese content of gray cast iron charge:

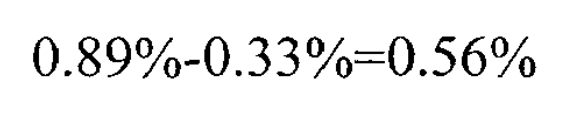

Amount of manganese still lacking in gray cast iron charge:

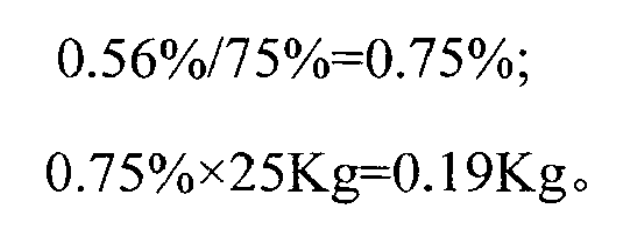

Supplement manganese with femn75:

8.Fill the above batching results into the batching table, as shown in Table 3.

| Name | Proportioning /% | Charge / kg | C charge /% | Si charge /% | Mn charge /% |

| Molten iron requirements | 100 | 25 | 3.15 | 1.8 | 0.8 |

| Burning loss | / | / | 5 | 0 | 10 |

| Charge requirements | / | / | 3,32 | 1,8 | 0.89 |

| Q12 pig iron | 75 | 18.75 | 3.3 | 0.83 | 0.10 |

| steel scrap | 25 | 6.25 | 0.05 | 0.10 | / |

| FeSi75 | 1.16 | 0.29 | / | 0.87 | / |

| FeMn75 | 0.75 | 0.19 | / | / | 0.56 |