1.Sample preparation

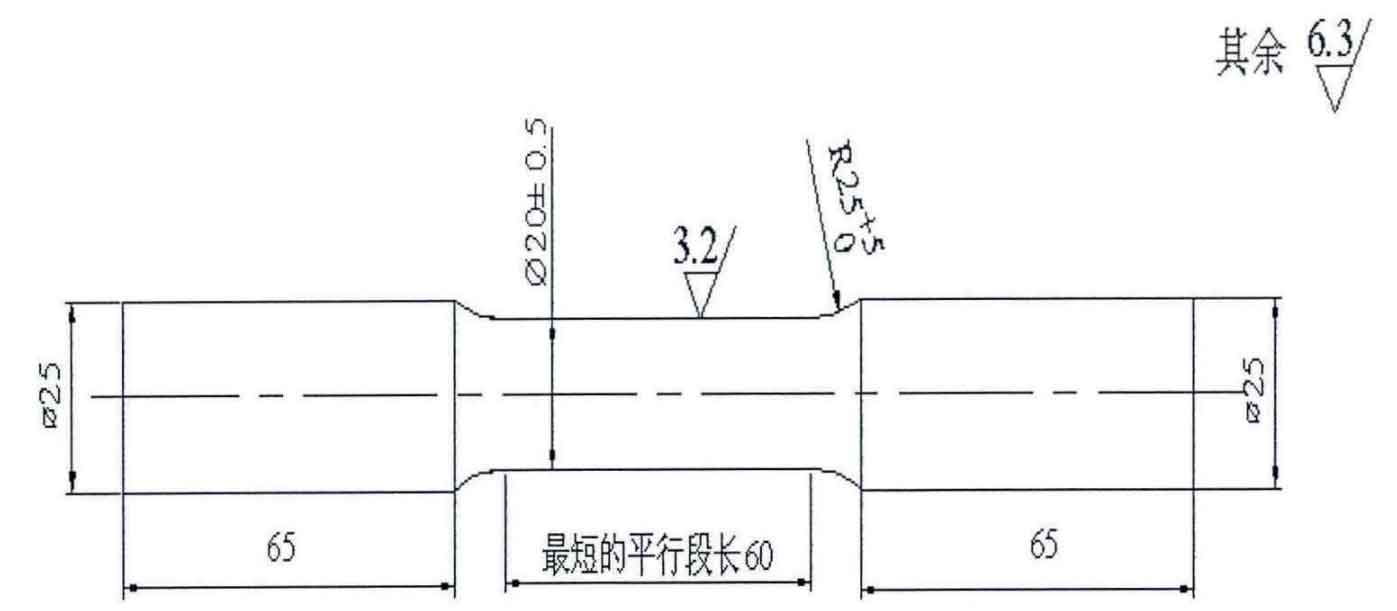

The tensile strength of low carbon equivalent gray cast iron was measured by hydraulic universal tensile testing machine. As shown in Figure, before the experiment Φ The 30mm sample is processed into a standard tensile sample (according to GB / t9439-1988), then the fracture of the tensile sample is cut off, and the remaining part is made into a cylindrical sample for metallographic and hardness tests.

2.Tensile strength test

Tensile strength is an important index used to determine the properties of gray cast iron. Hydraulic universal tensile testing machine is used to test the tensile strength of low carbon equivalent gray cast iron. Steps of measurement:

- First measure the maximum tensile force used when each group of samples is broken;

- Use the formula to calculate the maximum tensile strength of each group of samples;

- Take the average value of the maximum tensile strength of each group of samples.

The calculation formula of maximum tensile strength is:

S – cross sectional area of sample before breaking (mm2); F – maximum tension (n); σ B – tensile strength.

3.Hardness test

Hb-3000 Brinell hardness machine was used to test the hardness of low carbon equivalent gray cast iron. The load of the hardness machine was 750KG and the indenter was Φ 5mm steel ball. During the experiment, the instrument shall be placed stably, the station seat shall be kept horizontal, and the ground gray cast iron sample shall be placed stably on the station seat to ensure that the surface of the station seat and the gray cast iron sample are parallel to each other. Then take three different points on each gray cast iron sample for test, and take the average value after calculation.